Recently, many places across the country have entered high temperature weather of 35 ° C

or even 40° C, and the air conditioner is turned on almost 24 hours a day. If it is a traditional fixed-frequency air conditioner, then the electricity consumption of the air conditioner will be a small cost. With its high-efficiency and energy-saving advantages, the variable-frequency air conditioner quickly replaced the traditional fixed-frequency air conditioner and became the mainstream choice in the market. The AN1V PB312 series current sensor newly launched by CHIPSENSE has become the core component of current monitoring with the characteristics of "no insertion loss, wide range, extreme environmental tolerance, and easy installation of PCB", which can become the key technical fulcrum of the "energy-saving revolution" of the variable-frequency air conditioner.

The inverter air conditioner adjusts the compressor speed through the inverter, so that the air conditioner can operate at a low frequency to maintain a constant temperature after reaching the set temperature, avoiding frequent switching. The current sensor monitors the current change of the compressor in real time in the inverter air conditioner system, providing accurate current signals for the control system, so that the compressor can adjust the appropriate speed to always maintain the best efficiency range. Therefore, the inverter air conditioner saves 20% -30% energy than the traditional fixed frequency air conditioner by used CHIPSENSE current sensor.

The core advantages of the CHIPSENSE AN1V PB312 current sensor

1.Based on ASIC technology: CHIPSENSE AN1V current sensor is based on ASIC (application specific integrated circuit) chip design, which is superior to traditional Hall sensors in terms of processing speed, accuracy and reliability.

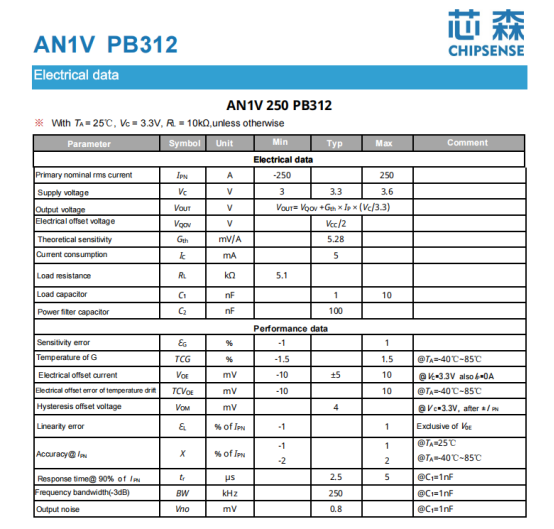

2.High accuracy: gain error ± 1%, linearity ± 1%, even in the face of transient current shock when the air conditioner compressor starts, CHIPSENSE AN1V PB312 current sensor can accurately capture fluctuations.

3.High response: CHIPSENSE current sensor’s response time is only 2.5 μs, ensuring that the air conditioning system adjusts the output frequency of the inverter in real time. In the scenario of rapid changes in compressor frequency, the current sensor can instantly feedback current changes to avoid energy efficiency losses.

4.Low loss: No insertion loss, avoiding the power loss of traditional shunt resistors.

5.Range coverage: CHIPSENSE current sensor from 50A to 300A range optional, suitable for all scenarios from household split machines to commercial central air conditioners.

6.Environmental tolerance: CHIPSENSE current sensor can work during -40 ° C to 150 ° C operating temperature range, easily cope with the stable operation of the air conditioner in high temperature exposure or low temperature frost environment.

The compressor is the "heart" of the air conditioner, and its operating state directly affects the energy efficiency of the whole machine. CHIPSENSE AN1V PB312 current sensor can monitor the current waveform when the compressor is started, running, and overloaded in real time:

Starting stage: Determine whether the motor is starting normally by the slope of the current rise to avoid stalling and burning. For example, when the current current rises too fast or too slowly, the sensor will immediately trigger the protection mechanism to prevent the motor from being damaged. CHIPSEN will be rigorous at every step.

Operation stage: CHIPSENSE combined with the ambient temperature and the set temperature, the output frequency of the inverter is dynamically adjusted, so that the compressor always runs in the best energy efficiency range. The current data fed back by CHIPSENSE current sensor helps the main control board to accurately control the compressor speed and avoid the ineffective energy consumption of the "big horse-drawn trolley".

Protection stage: When the current sensor exceeds the threshold (e.g. phase loss, short circuit), the protection mechanism is triggered within 0.1 seconds to cut off the power supply and prevent equipment damage.

Cost-effectiveness and delivery advantages of domestic compatible current sensor

For a long time, the high-precision current sensor market has been monopolized by international giants such as some big brands. Domestic air-conditioning manufacturers are not only facing the dilemma of "technology stuck neck", but also have to bear the pressure of high cost. The emergence of CHIPSENSE AN1V PB312 current sensor is like a key, opening the door to domestic substitution, and achieving "dimensionality reduction" with cost-effective and delivery advantages. CHIPSENSE current sensor is far ahead of other companies in domestic sensors.

Performance benchmarking: "China core" that exceeds international standards

CHIPSENSE AN1V PB312 current sensor confronts international giants and achieves a "counterattack" on key indicators:

Accuracy: Total error ≤ ± 1%, more accurate than ± 1.5% of other brand model like ACS758.

Temperature stability: -40 ° C to 150 ° C operating range, temperature drift is only ± 0.02%/° C, better than ACS770's ± 0.04%/° C.

Certification: through IEC 60664-1, IEC 61800-5-1 and other international standards, to meet the global market access requirements.Therefore, CHIPSENSE current sensor are very competitive to a large extent.

Cost and delivery: the "game-breaking power" of local production

Another major killer of CHIPSENSE AN1V PB312 high quality current sensor is the combination of "cost-effective + fast delivery":

Price: The price is less than half of the imported products, saving about 15 yuan in BOM cost for each air conditioner. Price is one of the major factors that CHIPSENSE considers for consumers.

Delivery cycle: Localized production shortens the delivery time to within 2 weeks, while imported products often require a long wait of 8-12 weeks. CHIPSENSE is more efficient than others.

Service: Provide customized range and packaging design services, respond to customer needs within 72 hours, and solve the pain points of "long delivery time and poor service" of imported products.

At present, CHIPSENSE AN1V PB312 current sensor already has been supplied in batches to an air conditioner head company. The R & D director of the company lamented: "The high precision and reliability of the AN1V PB312 current sensor from CHIPSENSE is not worse than that of expensive imports, which has improved the energy efficiency ratio of our inverter air conditioners a lot, and the current sensor market competitiveness has also improved."

Disassembling the air conditioner shell and pasting CHIPSENSE AN1V currrent sensor that is less than the size of a thumb on the PCB board seems low-key, but with the characteristics of "high precision, no loss, wide adaptation, and convenient installation", it may redefine the energy efficiency boundary of inverter air conditioners, and it is also a positive response to the goal of "double carbon". When thousands of air conditioners in households quietly save every kilowatt-hour of electricity, CHIPSENSE AN1V PB312 current sensor is illuminating the way to a green future with the "light of technology".

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806