Recently, the world's largest rooftop solar project was officially launched in Bahrain, with a single-unit capacity of 77 MWp. The project comprises 189 rooftop solar photovoltaic power stations and 900 ground-mounted solar photovoltaic installations, making it the world's largest industrial-scale on-site solar project to date, marking a new stage in the large-scale application of clean energy. However, no matter how large a photovoltaic power station is, it cannot function without the technical support of precise current monitoring. Current sensors are found in core equipment such as inverters and DC combiner boxes; these small components silently safeguard large-scale photovoltaic systems.

Technical challenges of current monitoring in large-scale photovoltaic power plants

Inverter Efficiency Loss:** Statistics show that a current sampling error exceeding 1% can lead to MPPT (Maximum Power Point Tracking) algorithm inaccuracies, resulting in a 2%–5% decrease in power generation efficiency. A monitoring error of >±2% for small currents of 10–50A will cause a 3%–8% MPPT efficiency loss. CHIPSENSE has a corresponding current sensor to address this issue.

Insufficient String-Level Monitoring Accuracy:** Power generation losses in a single string can reach 15%–30% due to shading, hot spots, or loose wiring. Without independent monitoring, anomalies are often masked by average values, leading to prolonged operation with inherent defects.

DC-Side Leakage Risk:** Insulation faults in high-voltage DC systems are difficult to detect in real time, and accumulated leakage current can cause fires or equipment damage.

Environmental Interference:** Strong electromagnetic interference and temperature fluctuations place stringent demands on the accuracy and stability of sensors.

High Environmental Adaptability Requirements:** Photovoltaic power plants are often located in extreme environments such as plateaus, deserts, and coastal areas. Sensors must operate stably at temperatures ranging from -40℃ to +85℃/105℃ and 95% humidity, and possess low-temperature drift characteristics.

Safety isolation and insulation level: 1500V systems are becoming mainstream, which places higher insulation requirements on sensors. Sensors used in combiner boxes must meet standards such as IEC61800-5-1 and IEC62109-1. This is also the standard for CHIPSENSE current sensors.

Traditional Hall current sensors are susceptible to problems such as temperature drift and poor linearity in high-current, high-precision scenarios. How to select a current sensor that is suitable for large-scale photovoltaic projects? Would a CHIPSENSE current sensor be a good choice?

Solutions and Technological Breakthroughs

Photovoltaic technology is now mature, and many solutions are available. The following are just a few examples for reference:

String-level intelligent monitoring (e.g., a certain Zhizhi solution)

Supports 24 string channels for current/voltage monitoring, with positioning accuracy down to the single-string level;

Integrates AFCI arc detection algorithm, identifying and alarming within 30 seconds;

Modular split structure, compatible with retrofitting old combiner boxes, no equipment replacement required.

High-precision current sensor applications

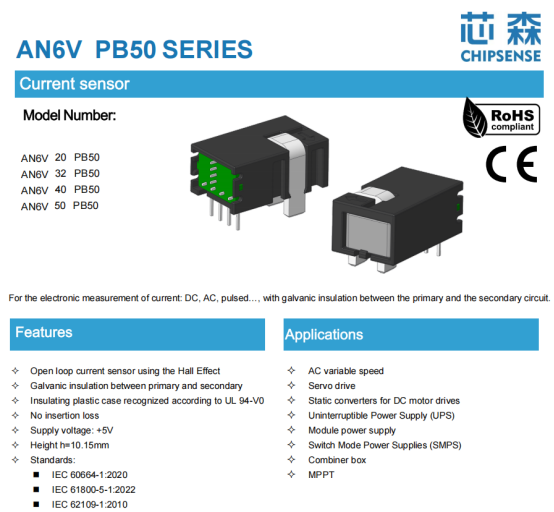

Open-loop Hall effect sensor (e.g., a certain Chip & Johnson solution CHIPSENSE AN6V current sensor):

Accuracy ±0.8%, small size suitable for residential inverters;

Insulation withstand voltage 3.0kV AC, creepage distance 5.5mm, meeting CAT III safety level.

Fluxgate Leakage Current Sensor (e.g., CHIPSENSE FR7V fluxgate leakag current sensor solution from a certain chip manufacturer):

Resolution reaches the milliampere level, accuracy ±0.5%;

Temperature drift is only ±1.5mV/k, zero-point offset at 85℃<0.1mA, supporting year-round calibration-free operation.

CHIPSENSE AN6V Current Sensor Technical Features:

This series is an open-loop current sensor based on the Hall effect from CHIPSENSE, employing an ASIC integrated design. Its compact design integrates significant functionality, with complete electrical isolation between the primary and secondary sides, no insertion loss, and compliance with international safety standards such as IEC 60664-1 and IEC 61800-5-1. In the photovoltaic field, it can be applied to MPPTs, combiner boxes, etc.

Key Features

High-precision measurement: Nonlinear error ≤0.5%, accuracy @ rated current ≤0.8%;

Wide temperature range: Operating temperature -40°C to 105°C, adaptable to extreme outdoor environments;

Fast response: Output bandwidth up to 250kHz, tracking time ≤2.5μs, suitable for high-frequency PWM control systems;

Insulation safety: 3kV AC withstand voltage, 5.4kV transient withstand voltage, meeting reinforced insulation requirements;

No insertion loss: Does not affect main circuit current, suitable for high-efficiency systems.

Application Scenarios of CHIPSENSE AN6V current sensor in Photovoltaic Systems

1. Inverter MPPT Optimization

Problem: Inverter MPPT algorithms rely on real-time current data; sensor errors can lead to power loss;

Solution: The current sensor of CHIPSENSE AN6V's high accuracy (≤0.8%) and low temperature drift (±3mV) ensure that the MPPT algorithm maintains optimal tracking efficiency across the entire temperature range;

Results: In a 50MW photovoltaic power plant, using CHIPSENSE AN6V current sensor improved inverter efficiency by 1.5%–3%, increasing annual power generation by approximately 200,000 kWh.

2.Over-current Protection for Combiner Boxes

Problem: Combiner boxes need to monitor branch currents in real time to prevent overload damage.

Solution: The current sensor of CHIPSENSE AN6V's fast response (≤2.5μs) and high precision achieve millisecond-level overcurrent protection.

Effect: Improves system reliability and reduces maintenance costs.

Solution Comparison: CHIPSENSE AN6V current sensor vs Traditional Hall Sensor

CHIPSENSE AN6V current sensor vs Traditional Hall Sensors

| Parameters | CHIPSENSE AN6V Current Sensor | Traditional Hall effect sensor |

| Accuracy (%FS) | ≤0.8% | ≤2% |

| Nonlinearity Error (%FS) | ≤0.5% | ≤1% |

| Operating Temperature Range (°C) | -40 to 105 | -20 to 85 |

| Response Time (μs) | ≤2.5 | ≥5 |

| Insulation Withstand Voltage (kV) | 3 (AC) / 5.4 (Transient) | 2 (AC) / 3 (transient) |

| Installation Method | PCB Soldering / Modular | Traditional Hall effect sensor |

Key findings: The AN6V current sensor achieves a balance between accuracy, stability, and ease of installation, making it the preferred choice for large-scale photovoltaic projects.

Installation and Usage Precautions

Mechanical Installation:

Use PCB soldering to ensure complete isolation between the primary busbar and the secondary circuit;

Follow the dimensions in the mechanical drawings to ensure adequate heat dissipation and insulation distance.

Electrical Connections:

Maintain a stable power supply voltage of 5V±0.5V to avoid measurement errors caused by low voltage.

Install a 1nF filter capacitor at the output terminals (Vout, Vref) to reduce high-frequency noise interference.

Safety Specifications:

Strictly adhere to IEC 61800-5-1 standards to ensure safe use of the sensor in hazardous voltage environments.

Regular calibration to prevent accuracy degradation due to aging.

Risk Warnings:

Avoid Overload: Prolonged use exceeding the rated current (e.g., CHIPSENSE AN6V current sensor-50 operating above 125A) will cause permanent damage to the sensor.

Environmental Adaptability: In high humidity or corrosive environments, a protective cover must be installed to prevent degradation of insulation performance.

Data Fusion: It is recommended to combine temperature, voltage, and other data to build a comprehensive fault diagnosis model to improve system reliability.

Conclusion: Precise Monitoring, Safeguarding the Future of Green Energy

The completion of the world's largest single-unit rooftop photovoltaic project is a milestone in the development of clean energy and an ultimate test of technical detail. CHIPSENSE AN6V current sensor, with its high precision, high reliability, and easy integration, has become a key choice as the "invisible guardian" of photovoltaic systems. In the pursuit of energy efficiency and security, accurate current monitoring is the cornerstone of every "green electricity" project. Choosing CHIPSENSE AN6V current sensor is not just choosing a sensor, but also choosing a long-term investment in system stability.

Discussion: In your photovoltaic or energy storage projects, which performance characteristic of the current sensor is most critical? Is it accuracy, response speed, or environmental adaptability? We welcome your sharing of your views.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806