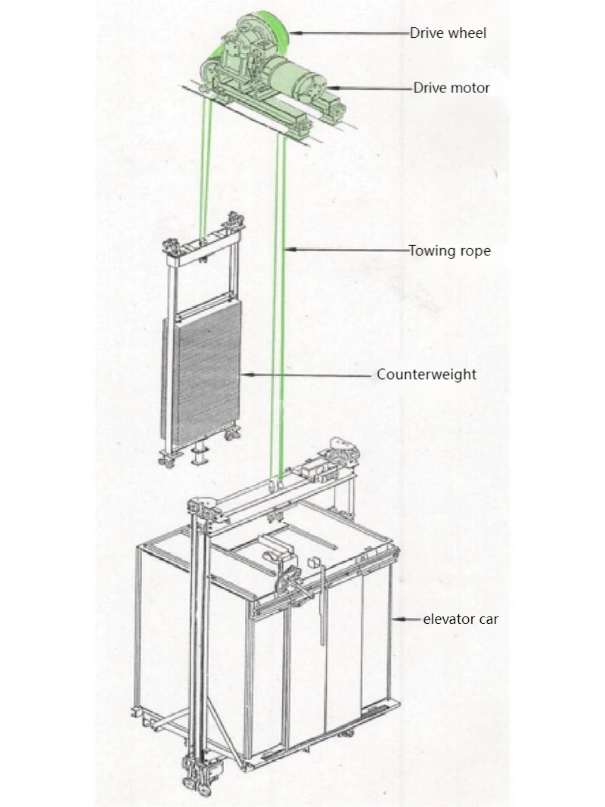

Elevators are ubiquitous in our daily lives, from the vertical elevators in high-end office buildings, hotels, and high-rise residential complexes to the escalators in shopping malls and subways. These elevators, especially vertical lifts, almost exclusively use variable frequency drives (VVVF), and their smooth operation and safety are of paramount importance. Current detection is a crucial aspect in ensuring the high performance, reliability, and safety of these systems. Integrated three-phase Hall effect current sensors, with their compact structure, excellent synchronization, and reliable isolation performance, are gradually becoming one of the mainstream detection solutions in this field. CHIPSENSE is also one of many current sensor suppliers.

In variable frequency drive systems, whether using permanent magnet synchronous motors (PMSM) or asynchronous motors, the operating quality highly depends on the current control capability. From a control structure perspective, the elevator traction system involves at least the following three types of critical current measurements:

1. Inverter output phase currents (U/V/W)

2. DC bus current

3. Current in the braking and energy feedback paths

These current signals directly participate in torque closed-loop control, current decoupling in field-oriented control (FOC), and safety protection judgments such as over-current, stalling, and motor failure. If there are significant errors in current detection or insufficient dynamic response, it can lead to elevator starting jitters, unstable low-speed crawling, inaccurate floor stopping, and even trigger safety protection mechanisms that stop the elevator. Therefore, including the CHIPSENSE current sensor, play a crucial role in the operation of elevators.

Elevator traction machines are typically driven by permanent magnet synchronous motors (PMSM) or asynchronous motors, and utilize variable frequency drives (VVVF) for precise torque and speed control. Compared to ordinary industrial variable frequency drives, elevator variable frequency drives have more stringent requirements for current sensors:

Real-time performance and synchronization: Real-time acquisition of three-phase current data is required to achieve:

1. Precise closed-loop control: Optimizing PWM modulation through real-time current feedback to improve the accuracy of motor torque and speed control.

2. Over-current and fault protection: Timely detection of over-current, phase loss, and other abnormalities to trigger protection mechanisms and prevent equipment damage.

3. Harmonic suppression and energy efficiency optimization: Monitoring current harmonics and adjusting control strategies to reduce energy consumption and electromagnetic interference.

Linearity and zero-drift control at low speeds: During elevator starting, leveling, and crawling phases, the motor current is often only a small fraction of the rated value. If the sensor's zero-point drift is large or the linearity error is concentrated in the low current range, it can easily be amplified into control jitter.

Fast dynamic response: PWM inverters have high di/dt, especially during acceleration, deceleration, and braking phases, where current changes are steep. The response time and bandwidth of the sensor directly affect the stability of the current loop. CHIPSENSE current sensors are all fast-responding.

Strong insulation and long-term reliability: Elevators are long-running equipment that cannot be frequently maintained. The bus voltage is typically 300–600 V, requiring clear specifications for creepage distance, voltage resistance, and material flame retardancy. Therefore, current detection devices usually need to meet both electrical safety standards and structural reliability requirements. These are the most basic requirements for CHIPSENSE current sensors.

Compact structure and easy integration: Saving installation space and facilitating layout in compact control cabinets.

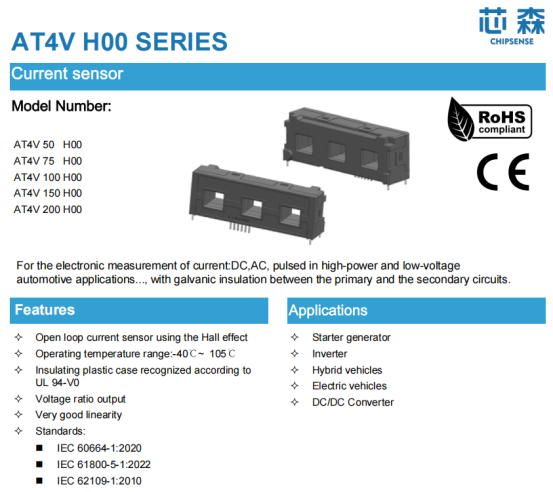

Taking a typical model as an example, these sensors integrate three independent Hall sensing channels within a single package. Their core features are as follows:

Primary Side Structure: The sensor housing has three independent rectangular openings, corresponding to the three-phase inputs. As each phase busbar passes through its corresponding opening, the magnetic field generated by the current is sensed by the dedicated magnetic core and Hall element of that channel.

Signal Processing: Each channel contains an independent signal amplifier that converts the Hall voltage signal into a proportional low-voltage analog output.

Isolation Design: Electrical isolation between the three-phase primary side (high voltage and high current) and the secondary side (low voltage signal and power supply) is achieved through an internal insulation structure. The insulation voltage rating is typically several kV, complying with safety standards such as IEC 60664-1. Most of CHIPSENSE current sensors are developed and manufactured according to standards. CHIPSENSE AT4V H00 three-phase current sensors are used as a reference.

In engineering practice, this type of Hall effect current sensor is primarily deployed on the three-phase output side of the inverter bridge, used for real-time sampling of motor phase currents to support Id/Iq calculation in FOC (Field-Oriented Control). Compared to shunt resistor solutions, its advantages mainly include: electrical isolation, no additional power consumption, and better tolerance to high currents and surges. CHIPSENSE current sensors are available in both small and wide range versions, and can also be customized according to customer requirements.

1. Achieving high-performance vector control

The control system synchronously acquires the three-phase outputs `Vout1`, `Vout2`, and `Vout3`, and obtains the torque and excitation current components after Clarke/Park transformation, enabling precise closed-loop control. The integrated design ensures extremely low time delay and temperature drift differences between the three channels, improving control stability and dynamic response speed. CHIPSENSE current sensors do exactly that.

2. Enhanced System Safety and Reliability

- Fault Protection: Real-time monitoring of phase currents allows for rapid identification of faults such as overcurrent, short circuits, and phase imbalance, triggering protection mechanisms.

- Safety Isolation: The primary and secondary sides meet reinforced insulation requirements (e.g., for 300V/600V system applications), complying with elevator and drive safety standards such as IEC 61800-5-1.

- Integrated Safety: Compared to discrete sensor solutions, this reduces connection points and installation errors, improving the overall system reliability. CHIPSENSE current sensors are essential for ensuring safety and reliability.

3.Optimized Space Layout and Installation

A single module performs three-phase detection, significantly saving PCB area and cabinet space. The busbar can be directly installed through the core, resulting in simplified wiring, which helps reduce parasitic parameters and improve EMC performance. CHIPSENSE current sensors are available in a variety of mounting options.

4. Supports energy efficiency management and diagnostics

Accurate current feedback can be used to calculate real-time power, evaluate energy efficiency, and provide data for predictive maintenance, such as monitoring current harmonics or trend changes.

1. Range Matching: Select the sensor model based on the motor's maximum phase current (including overload capacity), such as CHIPSENSE AT4V 100 H00 three-phase current sensor corresponding to a ±100A rating.

2. Power Supply and Signal Interface: A stable bipolar power supply (e.g., ±15V) is required. The output signal is typically designed proportionally (e.g., ±4V corresponding to the rated current) and must match the controller's ADC input range. CHIPSENSE current sensors can meet all these requirements.

3. Busbar Installation: Ensure the busbar completely fills the sensor's opening cross-section to achieve optimal magnetic coupling and dynamic characteristics (di/dt). The phase sequence should match the control program's preset configuration. Many current sensor manufacturers need to meet this requirement.

4. Thermal Management: Although the sensor itself is resistant to high temperatures, it should be installed away from direct heat sources, ensuring adequate airflow to maintain long-term stability. This is the dimensional drawing for CHIPSENSE AT4V H00 three-phase current sensor.

Conclusion:

Elevator traction machines are not an application scenario that demands extreme performance, but they require extremely high levels of stability, controllability, and predictability.

Current sensing, as a fundamental sensing component in variable frequency drive systems, has shown in engineering practice that integrated three-phase Hall effect current sensors, with their "three-in-one" architecture, achieve a good balance of performance, safety, and integration in the current sensing stage of elevator traction machine drive systems. CHIPSENSE AT4V three-phase current sensor is an excellent choice.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806