On February 2, 2026, the nationwide Spring Festival travel season officially begins. It is estimated that there will be 9.5 billion cross-regional passenger trips over the next 40 days. In particular, rail transportation is expected to see record-breaking daily peak passenger volumes, making operational safety and efficiency a key focus. Transportation authorities have made preparations in advance. The stable operation of traction systems, auxiliary power supplies, and energy recovery systems all rely on high-precision current monitoring technology. Especially in traction inverters, regenerative braking energy recovery, and auxiliary power systems, current sensors are not only the "gatekeepers" ensuring equipment safety but also crucial components for improving energy efficiency and maintenance efficiency. Many current sensor manufacturers are eager to take action. CHIPSENSE current sensors will also be involved.

Closed-loop (compensated) Hall effect current sensors detect magnetic field changes using a Hall element and compensate the magnetic field in real time through a feedback coil, thereby achieving high-precision current measurement. Compared to open-loop Hall sensors, the closed-loop design offers higher linearity, lower temperature drift, and faster response speed, making it particularly suitable for the complex electrical environments in rail transit.Some of CHIPSENSE's current sensors are excellent choices.

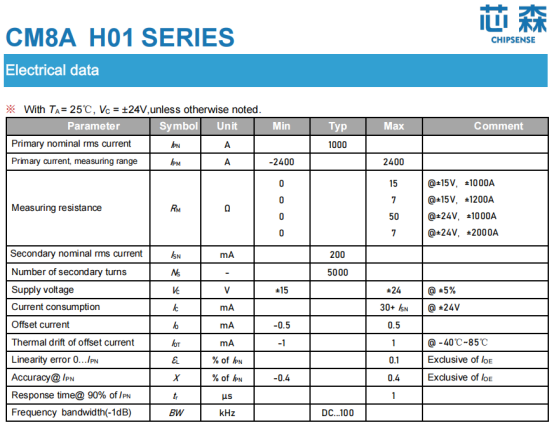

Taking CHIPSENSE CM8A H01 series current sensor as an example, its core technical parameters are as follows:

• Measurement range: Supports large current measurements up to ±2400A, covering the typical current requirements of rail transit traction systems.

• Insulation performance: 13.4kV AC insulation withstand voltage (compliant with IEC 60664-1 standard), 45mm air gap and 64mm creepage distance, ensuring safe isolation in high-voltage environments;

• Dynamic performance: 1μs response time, DC~100kHz bandwidth, capable of accurately capturing high-frequency current changes in PWM-controlled traction inverters;

• Environmental adaptability: Operating temperature range of -40°C to 85°C, UL94-V0 flame-retardant casing, meeting the stringent environmental requirements of rail transit. It's not just the CHIPSENSE CM8A series current sensor that can be used in this field; other current sensors from CHIPSENSE are also suitable, or can be customized.

1. Traction Inverter Current Monitoring

The traction inverter is a core power component of rail transit vehicles. Real-time monitoring of its output current is crucial for ensuring stable motor operation. Closed-loop Hall sensors can accurately measure three-phase current, preventing over-current damage and optimizing inverter efficiency through feedback control. In regenerative braking energy recovery systems, the sensors monitor the feedback current, ensuring efficient energy recovery and reducing energy waste. The three-phase current sensors of CHIPSENSE perform exceptionally well in the rail transit sector.

2.Auxiliary Power Systems

The auxiliary power system of rail transit vehicles provides stable power for lighting, communication, and control equipment. Closed-loop Hall sensors monitor the input and output currents of the DC/DC converter, promptly detecting abnormal fluctuations and preventing operational disruptions caused by equipment failures. CHIPSENSE current sensors can detect anomalies in a timely manner, reducing losses for customers.

3. Fault Diagnosis and Predictive Maintenance

By analyzing current wave-forms, closed-loop Hall sensors can identify potential problems such as insulation aging and poor contact. Combined with an intelligent operation and maintenance platform, this enables remote monitoring and early warning, transforming fault handling from "reactive maintenance" to "predictive maintenance," significantly improving operational safety. CHIPSENSE current sensors frequently receive positive feedback from customers in this regard.

1. Electromagnetic Compatibility

Strong electromagnetic interference in the rail transit environment may affect sensor accuracy. Therefore, shielding cables and filters should be used during installation to ensure signal stability. CHIPSENSE current sensors have very high accuracy requirements.

2. Installation and Heat Dissipation

During sensor installation, the primary conductor temperature should not exceed 100°C to avoid thermal drift affecting measurement accuracy. It is recommended to reserve sufficient heat dissipation space during the design phase and regularly check the tightness of the installation. CHIPSENSE current sensors come with installation instructions for customers.

3. System Integration

The closed-loop Hall sensor needs to be compatible with the on-board control system (TCMS) to ensure real-time data transmission. During the integration process, special attention should be paid to the compatibility of the communication interface and the synchronization of data acquisition.

Advantages of the CM8A H01's Mechanical and Electrical Design

• Mechanical Structure: Φ42mm primary conductor aperture, compatible with rail transit busbar dimensions; 4×M6 mounting holes ensure mechanical stability and reduce vibration effects.

• Electrical Interface: 4×M5 terminals, supporting 6.3×0.8mm quick connectors, simplifying field wiring and improving installation efficiency.

• Safety Standards: Complies with IEC 61800-5-1 standard, ensuring safe use in high-voltage environments and providing a reliable current monitoring solution for rail transit systems.

In recent rail transit projects, such as subway traction system upgrades and high-speed rail auxiliary power supply modifications, CHIPSENSE CM8A H01 current sensor has been widely used for current monitoring in traction inverters and energy recovery systems due to its high accuracy and stability. When selecting the device, it is recommended to choose the appropriate measuring resistor (R_M) and supply voltage (V_C) based on the actual current range, installation space, and environmental conditions to ensure optimal performance. If you have special requirements, CHIPSENSE current sensors can be professionally customized.

Closed-loop Hall effect current sensors play a "critical monitoring" role in rail transit, providing precise current data for traction systems, auxiliary power supplies, and energy recovery, supporting operation and maintenance decisions. However, users should strictly adhere to safety regulations and pay attention to technical details such as electromagnetic compatibility, heat dissipation, and system integration during application to ensure the sensors perform at their maximum efficiency. In electrified rail transit systems, closed-loop Hall effect sensors are not a "universal solution," but rather a key tool that provides reliable data support. CHIPSENSE current sensors will be the most suitable option among many current sensor suppliers.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806