Recently, I've been researching current monitoring solutions for electric vehicle powertrains and have found that integrated three-phase Hall effect current sensors have quite widespread applications and advantages in motor control, inverters, and battery management systems (BMS). The advantages of these non-contact measurement are particularly evident in high-voltage, high-current scenarios. However, I've also encountered some technical details and challenges in practical applications. Today, I'd like to discuss the technical characteristics and application limitations of Hall effect current sensors. Many current sensor manufacturers, including CHIPSENSE, can be used as references.

Basic Principles of Hall Effect Current Sensors

The basic principle of Hall effect current sensors can be summarized as follows: They utilize the Hall effect to convert the magnetic field signal generated by the current in a conductor into a directly measurable voltage signal, which is then amplified and processed for output. CHIPSENSE current sensor works on this principle. This non-contact measurement method means that the sensor itself does not need to be connected in series with the circuit under test, thus avoiding the power consumption and heat dissipation problems of traditional shunt resistors, making it particularly suitable for high-voltage and high-current applications.

Based on the different ways of processing the magnetic field in the magnetic core, there are two main categories:

Open-loop Hall Effect Current Sensors

The structure is relatively simple: the conductor under test passes through the magnetic core → a magnetic field is generated → the magnetic field directly acts on the Hall element in the air gap → the Hall voltage is linearly amplified and directly output. The principle is to use the Hall element to directly detect the magnetic field generated by the energized conductor, and then estimate the current magnitude based on this magnetic field strength. The advantages are low cost and small size. However, there are also disadvantages: accuracy and linearity are easily affected by the magnetization characteristics of the magnetic core, temperature drift is relatively large, and the response time is slower. Therefore, it is suitable for applications where high accuracy is not required, such as in frequency converters, UPS systems, and power supply equipment. In many of these scenarios, CHIPSENSE current sensor has received good feedback from numerous customers.

Closed-loop Hall effect current sensors (also known as zero-flux or magnetic balance type)

The structure is based on the open-loop Hall effect current sensor, with an additional compensation coil wound around the magnetic core. Instead of passively measuring the magnetic field, it actively generates a magnetic field equal in magnitude and opposite in direction to the magnetic field of the measured current, keeping the magnetic core in a zero-flux state. By measuring the compensation current required to generate this opposing magnetic field, the magnitude of the measured current is obtained. CHIPSENSE current sensors offer many model options in this regard. Its advantages include extremely high accuracy, excellent linearity, fast response speed, low temperature drift, and a wide bandwidth. Disadvantages include complex structure, higher power consumption, higher cost, and relatively larger size. It is typically used in applications requiring high performance, such as precision measurement, inverter control, servo drives, and power instruments.

Integrated Three-Phase Hall Current Sensor Characteristics

Working Principle:

The integrated three-phase Hall current sensor achieves accurate measurement of three-phase current based on the Hall effect. In the integrated three-phase Hall current sensor, the three-phase currents generate magnetic fields through the primary windings, which act on the Hall elements and induce voltage signals proportional to the currents. Subsequently, through amplification and signal processing circuits, the weak voltage signals output by the Hall elements are converted into digital or analog signals that are linearly related to the input current. The design of the three-phase Hall current sensor utilizes multi-channel synchronous sampling technology, ensuring no phase difference between the measured values of each phase current, thus meeting the high-precision and real-time current detection requirements of new energy vehicles. CHIPSENSE AT4V H00 current sensor is an excellent three-phase current sensor product. CHIPSENSE AT4V H00 current sensor is widely used in these fields.

CHIPSENSE AT4V H00 Series Current Sensors Introduction

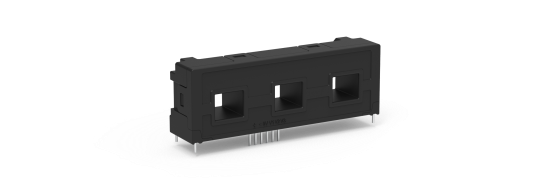

CHIPSENSE AT4V H00 series Hall effect open-loop current sensor is a high-performance current sensing solution designed for demanding three-phase drive systems. This series utilizes open-loop technology based on the Hall effect, with each sensor integrating three independent primary through-holes corresponding to the U, V, and W phases of the busbar, ensuring synchronous and accurate measurement of the three-phase currents. It is suitable for various applications including electric vehicles (EVs), hybrid electric vehicles (HEVs/PHEVs), elevator control systems, industrial inverters, and servo drives. CHIPSENSE AT4V H00 current sensor performs particularly well in applications such as elevators and automobiles.

Key Parameters:

• Measurement Range: CHIPSENSE typically supports ±50A to ±200A, with some models extending to ±600A peak current.

• Accuracy: Typical value ±1% (excluding offset voltage), linearity error ≤±0.5% IPN.

• Response Time: ≤5μs, bandwidth up to 50kHz (-3dB), suitable for high-frequency PWM control.

• Isolation Performance: AC isolation voltage 3.6kV (50Hz, 1min), transient withstand voltage 6.6kV (1.2/50μs), creepage distance 12.5mm, clearance 11.0mm.

• Environmental Adaptability: Operating temperature -40°C to 105°C, offset voltage temperature coefficient ±0.2mV/K, gain temperature coefficient ±0.02%/K.

The parameters of the CHIPSENSE AT4V H00 current sensor are superior to those of competing current sensor manufacturers.

A new energy vehicle contains a considerable number of core components that utilize a three-phase electrical system, such as three-phase motors, three-phase OBCs, and three-phase DC/DC converters. In terms of current detection, integrated three-phase current sensors, compared to traditional "three discrete single-phase sensors," CHIPSENSE AT4V H00 current sensor solve four key pain points:

Comparison Dimensions CHIPSENSE AT4V Integrated Three-Phase Measurement Discrete single-phase sensors New Energy Vehicle Application Value:

Measurement Synchronization Three-phase currents share the same magnetic core and signal processing circuit, resulting in consistent response times (3-5μs) and no phase difference. Three sensors are installed independently, leading to potential differences in response time (±1-2μs) and easily causing phase deviations. Motor vector control and OBC power factor correction require precise three-phase synchronous sampling to avoid control deviations.

Installation and Space Requirements Single unit (85g, compact size), allowing all three phases of the busbar to pass through simultaneously, simplifying layout. The three sensors require separate mounting, occupying three times the space, and resulting in complex wiring. The high-voltage compartment of new energy vehicles (PDU, motor controller) has limited space; integrated design can save more than 50% of installation space.

Interference Immunity Three-phase signals are transmitted along the same path, experiencing consistent electromagnetic interference, which can be canceled out through algorithms. The three sensors have different wiring lengths, leading to inconsistent interference that is difficult to cancel out. The high-voltage system has a complex electromagnetic environment (strong radiation from motors and inverters); integrated design improves measurement stability.

Cost and Reliability Single sensor set + 1 interface, reducing the number of components and connection points. Three sets of sensors + 3 interfaces, resulting in numerous connection points and a high failure rate. Reduces overall vehicle BOM cost and the probability of after-sales repairs (automotive-grade requirements: MTBF ≥ 10000h).

Application Scenario Analysis of Integrated Three-Phase Hall Current Sensors in New Energy Vehicles

Integrated three-phase Hall current sensors, with their high synchronization, compact structure, and automotive-grade reliability, have become a key sensing component in the high-voltage drive and control systems of new energy vehicles. Taking CHIPSENSE AT4V H00 series current sensors as an example, this device adopts a single-package design, integrating three independent Hall measurement channels (V1/V2/V3), sharing a single 80 mm×16 mm primary opening, supporting the simultaneous passage of three-phase busbars, and outputting proportional voltage signals through a 6-pin standard interface, significantly simplifying system integration. Therefore, many customers choose CHIPSENSE current sensors.

1. Three-Phase Permanent Magnet Synchronous Motor Controller (Inverter)

New energy vehicles commonly use three-phase permanent magnet synchronous motors (PMSM), whose vector control algorithm relies on high-precision, highly synchronized three-phase current feedback (Ia, Ib, Ic) to calculate the d/q axis current components.

The integrated design of CHIPSENSE AT4V series Hall effect current sensor demonstrates three major advantages in this scenario:

Synchronization Guarantee: The response time for all three channels is 3–5μs (typical value 3μs), with no inter-channel delay, ensuring accurate id/iq calculation and effectively suppressing torque fluctuations and motor vibration under low-speed or uphill conditions;

Consistent Accuracy:Linearity error ≤±0.5% IPN, gain error ≤±0.5%, and highly matched three-phase measurements help control current imbalance to a reasonable level, reducing additional copper and iron losses;

Structural Adaptability:A single elongated through-hole can accommodate standard three-phase busbars (total width typically ≤10 mm), allowing for direct integration into the inverter output terminal without requiring additional installation space.

2.Three-Phase On-Board Charger (OBC) Power Factor Correction (PFC)

High-end new energy vehicles (especially those with a range of ≥600km) often use OBCs with a three-phase 380V AC input. Their PFC circuits require precise monitoring of the three-phase current on the grid side to achieve a power factor of ≥0.99 and suppress harmonics.

Key adaptation capabilities of CHIPSENSE AT4V current sensors include:

Bandwidth matching:A -3dB bandwidth of up to 50kHz, allowing for complete reconstruction of high-frequency current waveforms at switching frequencies of 20–30kHz;

Three-phase synchronous sampling: Avoiding "phase shift" in PFC control due to amplitude or phase deviations between channels, preventing power factor reduction or exceeding THD limits;

High-voltage insulation compatibility: A 3.6kV isolation voltage and primary-to-secondary electrical clearance of 11mm will be in it , most of CHIPSENSE current sensors are meeting the reinforced insulation safety requirements of IEC 61800-5-1 and IEC 62109-1 for 300V systems.

3. Three-Phase Isolated DC/DC Converter

In 800V high-voltage platform vehicles, three-phase isolated DC/DC converters are used to achieve 800V→400V or 400V→12V conversion, requiring real-time monitoring of three-phase current for current sharing control and overload protection.

The adaptation characteristics of CHIPSENSE AT4Vcurrent sensor are reflected in:

•Wide current range coverage: Offers rated current (IPN) models from 50A to 200A, corresponding to measurement ranges of ±150 A to ±600 A (IPM), covering the needs of 10kW-class converters (e.g., CHIPSENSE AT4V 50 H00 supports ±150A overload);

• Integrated design saves space: The single-unit three-channel structure eliminates the need for multiple mounting points, making it particularly suitable for integration into space-constrained power distribution units (PDUs);

• Temperature stability: Typical gain temperature coefficient of ±0.02%/K (–40℃ to +105℃) ensures consistent three-phase current measurement across the entire temperature range, guaranteeing current sharing accuracy. CHIPSENSE AT4V current sensor is near a leader in the current sensor industry.

Risk Warnings and Usage Precautions

EMC Interference:

In high-voltage and high-frequency environments, it is recommended to place filtering capacitors near the sensor and keep it away from strong magnetic field sources.

The primary busbar should completely fill the vias to reduce parasitic inductance.

Temperature Effects:

When operating at 105°C for extended periods, ensure proper heat dissipation to avoid exceeding the temperature limit of the insulation material.

Regularly calibrate the offset voltage to compensate for temperature drift.

Installation Safety:

The sensor is an integrated device; after installation, the conductive parts must be covered with a protective cover to prevent electric shock.

The main power supply should have a disconnect mechanism for easy maintenance.

CHIPSENSE current sensors will always come with safety instructions for the customer.

Conclusion:

CHIPSENSE AT4V's "integrated three-phase measurement" is not an additional function, but a core feature specifically designed for the three-phase high-voltage components of new energy vehicles. Its accuracy and irreplaceable nature in various application scenarios are based on this deep integration with the electrical architecture of new energy vehicles.

In the future, the development direction of Hall effect current sensors may include material innovation, algorithm optimization, and ecosystem collaboration to further improve their performance and reliability under complex operating conditions. Not only the AT4V current sensor, but other current sensors from CHIPSENSE will also be the best choice for customers.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806