Driven by the goal of "double carbon", the construction of large-scale energy storage power stations has entered a fast lane. The new national standard for energy storage safety, "Safety Regulations for Electrochemical Energy Storage Power Stations", which will be officially implemented on July 1, 2023, requires that the energy storage system must have the ability of real-time monitoring, rapid cut-off, and two-way energy management. The National Energy Administration and other departments jointly issued the "Notice on Strengthening the Safety Management of Electrochemical Energy Storage" in April 2025, further emphasizing the work of improving standards and specifications and implementing safety management responsibilities.

This means that the coordination of the battery management system (BMS) and the bidirectional converter (PCS) becomes the key to ensuring the safe and efficient operation of the power station. CHIPSENSE products will also adapt to the development of the times.

What is a bidirectional converter and its functions and characteristics?

Bidirectional converter is a kind of power electronic device that can realize two-way conversion of electric energy. It can switch between alternating current (AC) and direct current (DC) flexibly and is widely used in energy storage systems, electric vehicles and renewable energy fields.

In the energy storage power station, the bidirectional converter (PCS, Power Conversion System) is the core equipment between the battery and the power grid. It realizes the bidirectional flow of electric energy through the switching control of power semiconductor devices (such as IGBTs and MOSFETs), combined with PWM modulation technology:

Charging mode (AC-DC rectifier mode): converts the alternating current of the grid into direct current to charge the battery pack.

Discharge mode (DC-AC inverter mode): Converts battery DC power into AC power for transmission to the power grid or for use by AC equipment.

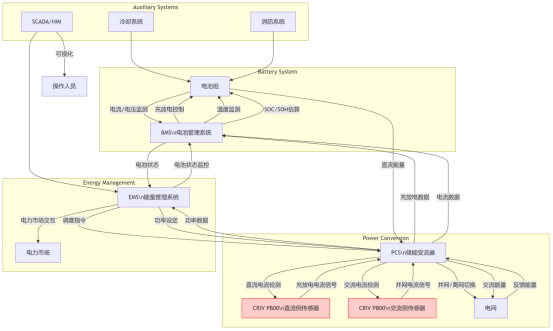

Energy storage equipment system topology diagram

Unlike unidirectional inverters, energy storage PCS integrates charge and discharge management functions, requiring frequent switching of charge and discharge modes and stable operation under different operating conditions. This two-way energy interaction places higher requirements on the high accuracy, wide dynamic range, fast response and anti-interference ability of current detection. If the detection delay or insufficient accuracy, it may cause battery overcharge and discharge, reduce the power quality of the grid, and even trigger system-level safety accidents. CHIPSENSE not only guarantees product quality, but also pays attention to protecting the safety of customers.

Technical requirements: high standards for current detection

In a PCS and BMS collaboration scenario, the current sensor needs to meet the following requirements:

Wide range and high accuracy: It can not only monitor the standby current of milliamp level, but also cover the main circuit of charge and discharge of hundreds of amps.

Wide bandwidth and fast response: ensure accurate capture of current mutations within milliseconds.

Electrical isolation and safety protection: Avoid high-voltage main circuits from interfering with the control board to ensure the safety of equipment and personnel.

Peer industry plan comparison

Current detection is one of the key technologies in PCS, which affects the control accuracy and stability of the system. Commonly used current detection technologies include resistance sampling and Hall sensor sampling. Although traditional resistive shunts have high precision, they are prone to heat generation under high voltage and high current conditions, and have limited safety isolation performance; while magnetic flux sensors have high precision, but are large in size and high in cost, which is not conducive to system integration. The industry needs a solution that combines high performance and system economy. CHIPSENSE made it.

Introduction to CHIPSENSE CR1V current sensor

The CR1V series current sensor launched by CHIPSENSE is a high-precision hall closed-loop sensor.

Characteristic

A closed-Loop (Compensation) current sensor based on hall principle

Insulation between primary and secondary sides

Raw materials comply with UL 94-V0

Excellent linearity

Exceptional accuracy

Low temperature drift

No insertion loss

Execution standards:

IEC 60664-1:2020

IEC 61800-5-1:2022

IEC 6 2109-1: 2010

Industrial application field

AC frequency conversion speed regulation, servo motor

Uninterruptible power supply (UPS)

DC Motor Driven Static Converter

Switching Power Supply (SMPS)

Welding machine power supply

Battery management

Wind energy inverter

Test and measurement equipment

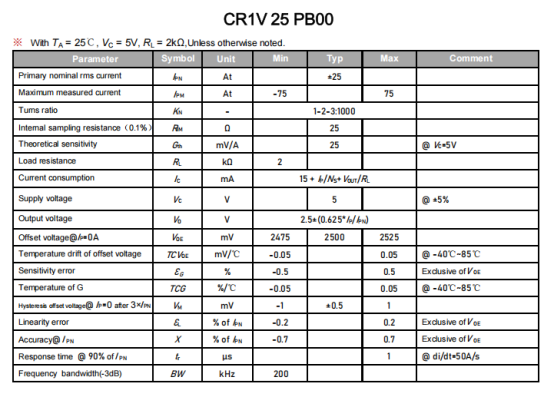

From the above parameter table, it can be seen that CHIPSENSE CR1V current sensor can be deployed in:

1.Applied to bidirectional converter (PCS)

Core requirements:

Accurate measurement of bi-directional current (charge/discharge mode switching).

High bandwidth to track fast-switching current wave-forms.

High isolation voltage ensures system safety (energy storage PCS usually involves hundreds of volts DC bus voltage).

Matching of CHIPSENSE CR1V PB00 current sensor:

Bidirectional measurement capability:

All models (CHIPSENSE CR1V 6/15/25 PB00 current sensor) measure within ± values (e.g. ± 6A, ± 15A, ± 25A).

The output voltage formula Vout = 2.5 ± (0.625 * Ip/Im) explicitly supports positive and negative current output (2.5V is the midpoint).

High dynamic response:

The tracking time is only 1 μs (@90% Im, di/dt = 50A/μs), and the bandwidth is 200 kHz, which can accurately capture the high-frequency switching current of PCS.

Security isolation:

Primary secondary insulation withstand voltage AC 2.5kV/50Hz/1min, transient withstand voltage 9kV.

The creepage distance is 15.5mm, the electrical gap is 6.35mm, which meets the basic insulation of 600V systems (IEC 61800-5-1, CAT III, PD2), and can be directly used for DC bus current detection.

Direct matching of application fields:

The specification explicitly lists "battery management" and "wind inverters" (topology similar to PCS for energy storage), proving that its design is for such scenarios. CHIPSENSE’s datasheets are clearly shown.

2.Applied to battery management systems (BMS)

Core requirements:

Monitor battery charge/discharge current (bi-directional).

High-precision measurement (SOC estimation relies on current integration)

Low temperature drift guarantees accuracy over the full temperature range.

Matching of CHIPSENSE CR1V PB00 current sensor:

High precision and low temperature drift:

Full-scale accuracy ± 0.7% (excluding offset voltage).

The gain temperature drift is ± 0.05%/℃, and the offset voltage temperature drift is ± 0.05 mV/℃ (-40 ℃~ 85 ℃), ensuring stable current measurement over a wide temperature range.

Bidirectional current detection:

The difference between charge and discharge current is also supported by ± 1m range and output voltage formula.

Low insertion loss:

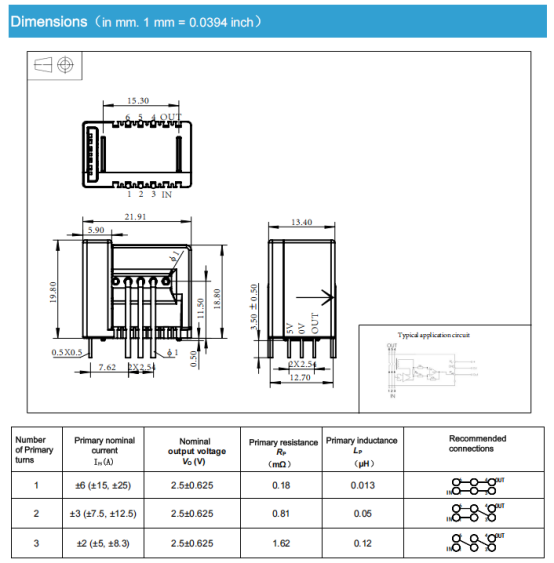

The primary resistance is extremely small (only 0.18 mΩ per turn), which hardly affects the efficiency of the battery circuit.

Compactness and safety:

CHIPSENSE CR1V PB00 current senseor is only 10g, the size is small, and it is easy to integrate into the battery module.

UL94-V0 flame retardant material meets battery system safety requirements.

Conclusion

Driven by high-voltage policies and market expansion, energy storage systems pose an unprecedented challenge to the collaboration between PCS and BMS. CHIPSENSE CRIV PB00 series current sensor is an ideal choice for PCS and BMS current detection in energy storage power plants due to its bi-directional measurement, high precision, safety isolation and dynamic response characteristics, providing a solid guarantee for the safe and efficient operation of energy storage power plants. CHIPSENSEN current sensor will keep it.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806