In industrial inspection, new energy operation and maintenance, and equipment commissioning scenarios, real-time data viewing of Hall effect current sensors is crucial for ensuring safe system operation and quickly troubleshooting faults. Traditional methods relying on professional industrial control computers or wired instruments suffer from cumbersome operation and lack of flexibility, failing to meet the demands of mobile and convenient use. With the development of the Internet of Things and wireless communication technologies, real-time data viewing of Hall effect current sensors has evolved into diverse solutions. This article will analyze the core technical logic, mainstream implementation methods, and portable solution selection to help users efficiently obtain real-time data. CHIPSENSE current sensors also have many wide-ranging application areas.

I.The Underlying Logic of Real-Time Monitoring: The "Three Steps" of Data Transmission

The process from data acquisition to presentation of Hall effect current sensor data involves three core stages: "signal conversion - transmission - parsing and display." The key to real-time performance lies in shortening the delay in each stage and ensuring synchronous data feedback:

1. Signal Conversion Layer: The sensor converts the collected current signal (AC/DC) into a standardized electrical signal (such as a 4-20mA analog signal or a digital pulse signal). This relies on high-precision Hall effect elements and signal conditioning circuits to ensure that the original data is undistorted;

2. Data Transmission Layer: The standardized signal is transmitted to the terminal device through wired or wireless communication protocols. Mainstream protocols include wired (RS485, Modbus TCP), short-range wireless (Bluetooth, Wi-Fi), and wide-area wireless (4G/5G, LoRa). The transmission rate and delay directly affect real-time performance;

3. Data Interpretation and Display Layer: Terminal devices (computers, mobile phones, tablets) interpret the signals through software, displaying them intuitively in the form of numbers, curves, and dashboards. The real-time processing capabilities and interface design of the software determine its ease of use. Many current sensors now have this function.

II.Four Mainstream Real-Time Viewing Solutions: From Local to Remote, from Professional to Portable. All of these operations rely on the help of current sensors.

Solution 1: Direct Hardware Connection – The "Zero Latency" Option for Local Debugging

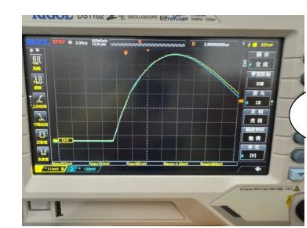

Connect the Hall effect current sensor directly to a computer or dedicated handheld instrument via a data cable (USB, RS485-to-USB cable), and use the accompanying software (such as sensor manufacturer's customized tools, general serial port assistant, or LabVIEW) to read data in real time.

Core Advantages: Extremely low latency (≤10ms), high data accuracy, no network required, unaffected by environmental interference, suitable for equipment factory debugging, laboratory calibration, and other scenarios;

Key Operating Points: Requires matching the sensor communication protocol (such as Modbus RTU), setting the correct baud rate (commonly 9600/19200bps), data bits, and parity bits; the handheld instrument needs to support the sensor signal type (analog/digital), and some instruments can directly display the current value without additional software;

Limitations: Limited by cable length (usually ≤10 meters), unable to view remotely, poor portability, suitable for short-term use in fixed scenarios.

Solution 2: Bluetooth/Wi-Fi Mobile App – The "Portable Choice" for On-Site Inspections

Utilizing the Bluetooth (BLE 5.0 and above) or Wi-Fi module built into the sensor, a connection is established with a mobile phone/tablet app for real-time data viewing, making it the most convenient on-site solution currently available.

Core Advantages: No cables required, operating range of 10-100 meters (Bluetooth/Wi-Fi), intuitive APP interface (supports real-time curves, numerical display, and anomaly alarms), some support data export (Excel format) and historical record queries;

Applicable Scenarios: Outdoor photovoltaic panel current inspection, workshop equipment current spot checks, temporary fault diagnosis, and other mobile scenarios;

Selection Considerations: Confirm whether the sensor has a built-in Bluetooth/Wi-Fi module, and whether the APP supports the target sensor model (some manufacturers provide universal APPs compatible with mainstream brands); prioritize APPs that support offline caching to avoid data loss after disconnection.

Solution 3: 4G/5G Cloud Platform – The "Borderless Solution" for Remote Monitoring

Hall effect current sensors upload data to the cloud platform via an IoT gateway (supporting 4G/5G and LoRa). Users can access the data anytime, anywhere via computer web pages or mobile apps, enabling centralized management across different regions and multiple devices.

Core Advantages: Breaks through spatial limitations, supports remote real-time viewing, historical data tracing (data up to one year can be retrieved), and unified management of multiple sensors (supporting up to thousands of devices). Some platforms also offer data anomaly alarms (SMS, APP push notifications) and data analysis functions;

Implementation Requirements: Sensors must support IoT protocols such as MQTT and HTTP; the gateway needs to be configured with a data SIM card or connected to a local area network; and the cloud platform requires device registration and parameter configuration;

Applicable Scenarios: Suitable for scenarios requiring long-term remote monitoring, such as distributed photovoltaic power plants, remote pumping stations, and high-voltage transmission lines. Portability is achieved through "anytime, anywhere access," eliminating the need to be on-site. CHIPSENSE current sensors have been used in this field.

Solution 4: Handheld Integrated Terminal – The "All-in-One Tool" for Industrial Sites

A professional handheld terminal (such as an industrial PDA or customized current monitor) integrates data acquisition, analysis, and display. It can connect directly to Hall effect current sensors via wired (RS485) or wireless (Bluetooth) connections to display current data in real time. CHIPSENSE current sensor has already begun to be used in this application field.

Key Advantages: Features industrial-grade protection (IP65 and above), resistant to high and low temperatures and vibration, suitable for harsh industrial environments; operates independently without relying on a computer or mobile phone, performing data viewing, recording, and export; some models support offline storage of over 100,000 data points;

Applicable Scenarios: On-site inspection scenarios in chemical workshops, outdoor engineering, mining equipment, and other environments requiring high equipment protection;

Purchasing Considerations: Focus on the terminal's signal compatibility (supports analog/digital sensors), battery life (single charge ≥ 8 hours), and data export methods (USB/Bluetooth).

III.Portable Solution Selection Guide: Precise Matching Based on Application Scenarios

(I) Scenarios Prioritizing Bluetooth/Wi-Fi Mobile Apps

Core needs: Quick on-site viewing, temporary inspections, and no complex operations required;

Applicable conditions: Sensors with built-in Bluetooth/Wi-Fi modules, and the operating environment is free from strong electromagnetic interference (e.g., away from frequency converters and high-voltage equipment);

Recommended combination:Hall effect current sensor supporting BLE 5.0 + general-purpose current monitoring app (such as "Industrial Sensing Assistant"), low cost, simple operation, and all operations can be completed on a mobile phone.

Therefore, CHIPSENSE has higher requirements for its own research and development of current sensors.

(II) Scenarios where 4G/5G cloud platforms are preferred:

Core needs: Remote monitoring, multi-device management, long-term data traceability;

Suitable conditions: Requires 24/7 uninterrupted monitoring, and network coverage (4G/5G or broadband) is available on-site;

Recommended combination: Hall effect current sensor with IoT module + lightweight cloud platform (such as Alibaba Cloud IoT, Huawei Cloud IoT), supporting remote viewing via mobile app, real-time push notifications for abnormal situations, balancing portability and practicality. In addition, CHIPSENSE current sensors are also developing new application areas for their products.

(III) Scenarios where handheld terminal integrated devices are preferred:

Core needs: Use in harsh environments, offline data storage, high reliability;

Suitable conditions: Industrial workshops, outdoor environments without network access, high requirements for equipment protection;

Recommended combination: Industrial-grade handheld terminal + wired/wireless Hall effect current sensor, the terminal supports waterproof and dust-proof features, and has a long battery life, suitable for long-term on-site operation. CHIPSENSE current sensor is an excellent choice.

IV.Implementation Considerations and Optimization Techniques

1. Communication Protocol Matching: Regardless of the chosen solution, confirm in advance that the sensor's supported communication protocol (such as Modbus, HART, MQTT) is compatible with the terminal equipment/software to avoid connection issues;

2. Signal Interference Protection: When used in strong electromagnetic environments (such as near substations or frequency converters), prioritize wireless solutions (Bluetooth/Wi-Fi) or shielded cables to reduce data fluctuations caused by signal interference;

3. Power Supply Guarantee: For portable solutions, pay attention to power supply. Bluetooth/Wi-Fi sensors can use lithium battery power (battery life ≥ 12 hours), and handheld terminals should be equipped with backup batteries to avoid power outages on site;

4. Data Security: Cloud platform solutions should enable encrypted data transmission (HTTPS/MQTTs) and set access permissions (such as account passwords, role-based access control) to prevent sensitive data leakage;

5. Function Simplification: In portable scenarios, prioritize tools with focused functionality (e.g., only needing to view values, without complex data analysis) to avoid cumbersome software/device operation affecting efficiency. CHIPSENSE current sensors are very mature devices in this respect.

V.Summary

Real-time viewing of Hall current sensor data has been achieved with "portability and versatility," with Bluetooth/Wi-Fi mobile apps, 4G/5G cloud platforms, and integrated handheld terminals being the most mainstream portable solutions. When choosing a solution, it's crucial to consider the specific application scenario: Bluetooth/Wi-Fi apps are suitable for quick on-site viewing, 4G/5G cloud platforms for remote monitoring, and industrial-grade handheld terminals for harsh environments. The core principle is "matching needs," avoiding the pursuit of comprehensive functionality. Focusing on compatibility, ease of operation, and data reliability is key to efficiently obtaining real-time data and supporting equipment maintenance and troubleshooting.

It's not just current sensors; CHIPSENSE current sensors will also play a crucial role in this.

Frequently Asked Questions

Q1: How can I achieve portable viewing with traditional Hall effect current sensors that don't have a built-in wireless module?

A: You can upgrade traditional wired sensors to wireless transmission by connecting an external wireless conversion module (such as an RS485 to Bluetooth or RS485 to Wi-Fi module). Then, you can view the data using a mobile app. This is a low-cost and simple modification that doesn't require replacing the sensor.

Q2: Which solution, Bluetooth or Wi-Fi, is more suitable for portable viewing in the field?

A: The Bluetooth solution is suitable for short distances (≤30 meters) and single-point viewing, requiring no network and offering simpler operation. The Wi-Fi solution is suitable for medium distances (≤100 meters) and simultaneous viewing on multiple devices. It can connect to the internet for data synchronization and requires Wi-Fi coverage on-site. The choice depends on the usage distance and the number of devices.

Q3: How can I ensure data accuracy when viewing data using a mobile app?

A: First, choose an app developed by a reputable manufacturer to avoid data distortion caused by inferior third-party software; second, calibrate the sensor and the app using a standard current source before use; finally, avoid using it in environments with strong electromagnetic interference to reduce signal interference.

Q4: Is the latency of remote viewing on the cloud platform high? Can it meet real-time monitoring requirements?

A: The latency of 4G/5G cloud platforms is typically 100-500ms, while LoRa platforms have slightly higher latency (500ms-1s). Both can meet the real-time requirements of industrial monitoring and equipment maintenance scenarios; for millisecond-level latency (such as equipment debugging), it is recommended to choose a local hardware direct connection or Bluetooth solution.

Q5: What is the battery life of the handheld terminal? Can it meet the needs of long-term field work?

A: Industrial-grade handheld terminals typically have a battery life of 8-12 hours per charge, support fast charging (2 hours to fully charge), and some models have replaceable batteries, meeting the needs of daily field inspections; for longer working hours, a power bank or solar charging panel can be used to ensure continuous power supply.

In these application scenarios, the CHIPSENSE current sensor plays a crucial role.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806