From August 1, 2025, the two major standards on new energy vehicles and their charging piles, "Safety Requirements for Electric Vehicle Power Supply Equipment" (GB 39752-2024) and "Safety Requirements for Electric Vehicle Conductive Charging Systems" (GB 44263-2024), will be implemented. The implementation of the new standard will further improve the safety level of electric vehicle power supply equipment and charging systems, and ensure the safety of life and property of electric vehicle users. This paper only discusses the application of PFC module current detection in DC charging piles above 600KW. CHIPSENSE current sensor is also involved.

What is DC fast charging?

DC fast charging is an efficient charging method in electric vehicle charging technology, which can replenish a large amount of power to the vehicle in a short time and significantly improve the charging efficiency. The principle is to convert AC power into high-voltage direct current (usually 300-900V), bypass the on-board charging OBC, and directly deliver it to the power battery pack of the electric vehicle. Now the ultra-fast charging piles (such as 480kW, 600kW) on the market can even achieve "charging for 5 minutes and battery life of 200 kilometers", which greatly shortens the charging time. CHIPSENSE also takes into account the customer's time cost.

The core components of DC fast charging

1.Power conversion module: Its function is to convert the AC power input from the power grid into the high-voltage DC power required by the battery, and it is the core power source for realizing fast charging.

2.Control system: Coordinate the work of each module of the charging pile, communicate with the vehicle BMS (battery management system), and dynamically adjust the output voltage and current to ensure charging safety and efficiency.

3.Cooling system: During high-power fast charging, the power module will generate a lot of heat (for example, the heat dissipation demand of 600kW charging piles can reach tens of kilowatts per hour), and excessive temperature will lead to device damage. Supercharging piles above 400KW use liquid-cooled radiators based on water cooling.

4. Input and output protection devices:

Input side: circuit breaker (overload/short circuit protection), lightning protection module (to prevent lightning damage to equipment), leakage protector (to ensure personnel safety).

Output side: DC contactor (to quickly cut off the output and protect the battery in case of failure), voltage/current sensor (to monitor the output status in real time).

The "heart" of DC fast charging - power module

In the power conversion module of the overcharged pile, the power module is the core unit to realize the power conversion and power output, which directly determines the power level, conversion efficiency and stability of the overcharged pile. It usually exists in a modular design. For example, the 600kW pile is often composed of multiple 100-150kW modules in parallel, and the ultra-high power output (such as 480kW, 600kW or even 1000kW or more) is achieved by combining.

The power module is an integrated "power conversion unit", and the core structure includes the following parts:

| Core component | Functions | Key components/technologies |

| Rectifier unit | Converting the input alternating current (AC) to direct current (DC) is the first step in AC-DC conversion. | Three-phase bridge rectifier circuit is adopted, and the core device is diode or IGBT (controllable rectifier). |

| Filter unit | Filter out the ripple (current fluctuation) in the rectified DC, and output a smooth DC voltage. | Electrolytic capacitors, thin film capacitors (high voltage resistance, low ESR, suitable for high-frequency scenarios). |

| DC-DC conversion unit | Adjust the voltage/current of the rectified DC to match the high voltage output required by the battery (e.g. from 500V to 800V). | High-frequency transformers (for electrical isolation), IGBTs or SiC MOSFETs (switching devices). |

| Drive and protection circuit | Drive the switching device (IGBT/SiC) to work and monitor the module status (overvoltage, overcurrent, overheating). | Driving chips (e.g. isolated gate drivers), sensors (voltage/current transformers). |

Power Factor Correction PFC (Power Regulation Center) of Supercharged Pile Rectifier Unit

In the rectifier unit of the overcharged pile, PFC (Power Factor Correction) is one of the core technologies. Its function is to improve the waveform of the input current of the power grid, increase the power factor, reduce the harmonic pollution to the power grid, and at the same time improve the power conversion efficiency. Its performance directly affects the compatibility, operation efficiency and power stability of the overcharged pile with the power grid. The commonly used PFC technologies in the overcharged pile are divided into passive PFC and active PFC. Active PFC has become the mainstream due to its performance advantages, and no PFC exists in the overcharge. All CHIPSENSE current sensors are developed in strict accordance with standards.

PFC current detection

In the PFC circuit, the current detection is to collect the input current in real time and provide feedback signal to the control chip to ensure that the input current waveform follows the voltage waveform in a sinusoidal curve, so as to achieve high power factor and low harmonics.

Three Core Objectives of PFC Current Detection

1.Waveform tracking: Make the input current waveform and the input voltage waveform in phase (sinusoidal) to ensure that the power factor is close to 1.

2. Protection of limited viewership: real-time monitoring of current peak or effective value to prevent circuit damage due to overcurrent (such as load mutation, short circuit).

3. Harmonic suppression: By accurately detecting current distortion and adjusting the control strategy of the switching device, the total harmonic distortion rate (THD) can be reduced.

PFC Current Detection Objects and Scenes

The current to be detected in the PFC circuit mainly includes:

AC input current: directly reflects the current waveform on the grid side, used to determine power factor and harmonic level.

Inductor current: In Boost-type PFC (Supercharged Pile Mainstream Topology), the inductor is the core of energy storage, and its current change directly reflects the energy conversion state, which is the key basis for controlling the switch to turn on/off.

DC side current: In some scenarios, the DC current output of the PFC needs to be detected for overcurrent protection or power closed-loop control.

Common current detection schemes and principles

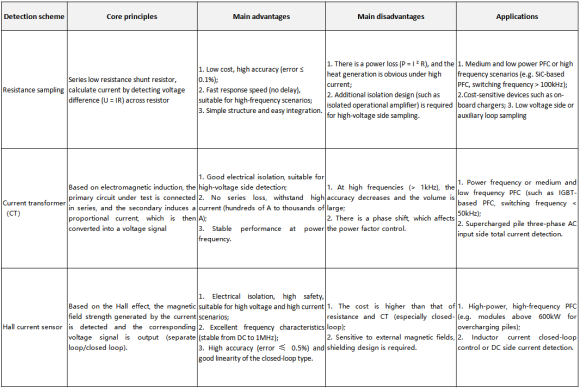

According to the different detection components, PFC current detection is mainly divided into three categories: resistance sampling, current transformers, and Hall sensors. The following is a comparison of the three types of solutions:

PFC current detection is the dual core of "waveform correction" and "system protection". Under the new national standard, resistance sampling is not suitable for overcharging because it is prone to power loss and obvious heat generation. Current transformers (CT) need compensation circuits or combine with other detection methods to meet the requirements of the new national standard for charging efficiency and power quality. Hall current sensors meet the requirements of the new national standard and are a better choice. Its electrical isolation, high-frequency characteristics are good, and its accuracy and linearity meet the needs of power optimization and safety protection. It can be competent for 800A high current and high-frequency switching circuit detection. CHIPSENSE has different currents for different applications.

Introduction to AN3V current sensor of CHIPSENSE

AN3V PB35/55 series current sensor is a brand-new open-loop Hall current sensor product specially built by CHIPSENSE for high-current detection scenarios.

This series of CHIPSENSE products precisely focuses on the power supply, photovoltaic, energy storage and other industries, and is deeply in line with the high reliability and high performance of current measurement in these fields

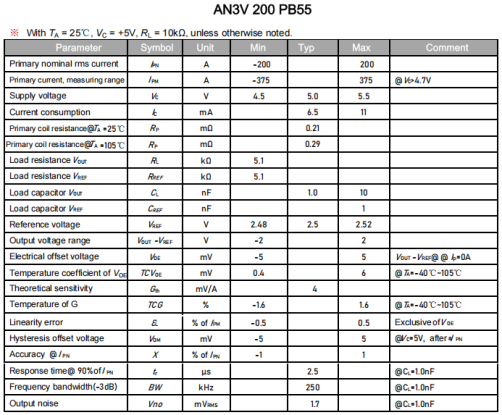

The demanding requirements of consistency. CHIPSENSE new AN3V series current sensors mainly includes AN3V PB35/PB55 and other models current sensors, covering the rated measurement range from 80A to 200A. CHIPSENSE current sensor not only does it ensure measurement accuracy, but also greatly improves the dynamic measurement range, reliability and excellent linearity.

Characteristic

Open loop current sensor based on hall principle

Insulation between primary and secondary sides

Raw materials comply with UL 94-V0

No insertion loss

Power supply voltage: + 3.3V

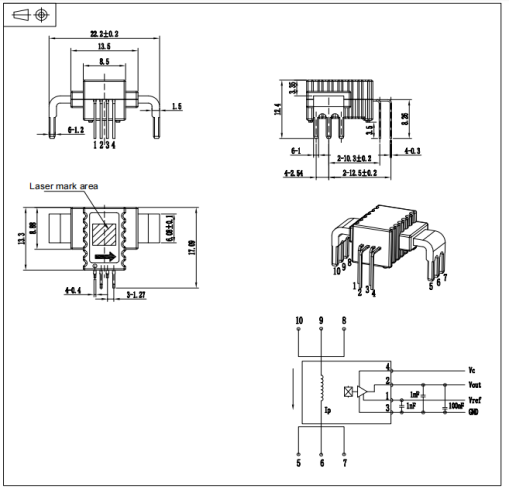

Height h = 8.7mm

Execution standards:

IEC 60664-1:2020

IEC 61800-5-1:2022

IEC 6 2109-1: 2010

Parameter characteristics:

Power supply: + 5V/3.3V

Rated range: ± 80~ 200A

Measuring range: ± 80~ 375A

Working range: -40~ 105 ° C

Typical accuracy: 1%po

Response time: 2.5 μs

Insulation voltage: 4.3kV

Bandwidth: 250kHz

Linearity: 0.5%

Dimensions

Conclusion: The Precision Guardian of Surging Power - CHIPSENSE

The DC fast charging pile above 600kW under the new national standard is powered by the efficient conversion of modular power supply, and the PFC module, as the "energy inlet", its stable and efficient operation cannot be separated from accurate, fast and safe current monitoring technology. The open-loop Hall current sensor ASIC solution represented by AN3V of CHIPSENSE has become one of the mainstream components to support the new generation of high-power PFC circuits with its comprehensive advantages of zero loss, microsecond response, native isolation and high integration.They are like sophisticated "current sentinels", silently guarding the efficient operation of the PFC module, laying a solid technical foundation for the new infrastructure's ultra-fast charging network. So CHIPSENSE is a good choice.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806