Recently, Guangdong, Zhejiang, Jiangsu, and other regions have successively introduced special subsidy policies for the digital transformation of small and medium-sized enterprises. For example, in the Pearl River Delta, subsidies for the digital transformation projects of SMEs are 40%, while in eastern, western, and northern Guangdong, the subsidies increase to 50%, and the 'equipment data collection coverage rate' is explicitly included as an acceptance indicator. However, many SMEs are still using old motors and inverters that are over 10 years old, lacking real-time monitoring methods and key operational data such as current and temperature, leading to the risk of unplanned downtime. Installing sensors has become the mainstream solution for upgrading old motor equipment. CHIPSENSE current sensor offers some good solutions.

The purpose of upgrading and retrofitting old motors is to improve the performance of existing motors through technical means, maximize their performance utilization, and extend their service life.

The space and wiring of old equipment are already fixed, so the retrofit space is limited and requires small, non-contact solutions.

The retrofit needs to control costs; otherwise, it would be better to purchase new equipment instead of replacing old ones. This requires considering the cost of the sensors themselves and installation expenses.

Commonly retrofitted motors have a power range of 55KW~280KW, but small and medium power motors (such as household appliances and small industrial equipment) are more common.

High-precision control is usually not required, but stability and reliability are needed, such as start-stop, speed regulation, or energy-saving optimization.

Motor faults such as overload, stall, and phase loss often manifest through abnormal currents. In the past, with old motors, faults could only be identified by listening to sounds or feeling the machine's temperature by hand, making it difficult to pinpoint the problem. Monitoring current during motor operation is to grasp the load status in real time, promptly detect overload or electrical faults, prevent equipment overheating and damage due to abnormal current, and at the same time optimize operational efficiency and extend service life.

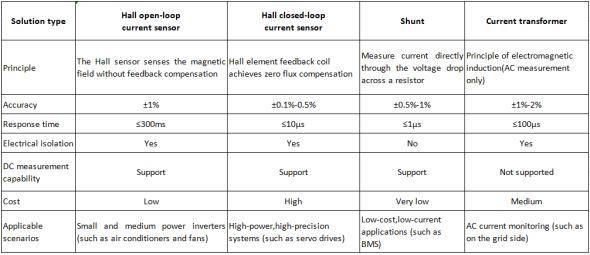

Common solutions for motor current detection

Here is a detailed comparison of four commonly used current detection schemes in the inverter-driven motors, including principles, features, applicable scenarios, and key parameters:

For the needs of retrofitting old motors (low cost, low precision, ease of installation), Hall open-loop current sensors are the most suitable current detection solution.

The Hall open-loop current sensor is a current detection device based on the principle of the Hall effect. It measures current by sensing the magnetic field intensity at the air gap of the magnetic core with a Hall element. It features a simple structure and low cost, making it suitable for AC/DC current monitoring. CHIPSENSE current sensors are meet these needs.

Its core principle is as follows: the primary current Ip generates a magnetic field, which is concentrated by the magnetic core. A Hall sensing chip then senses the magnitude and direction of the primary current Ip at the air gap of the magnetic core. The output voltage of the Hall sensing chip, after passing through a signal processing circuit, allows the sensor's output to accurately reflect the measured current value.

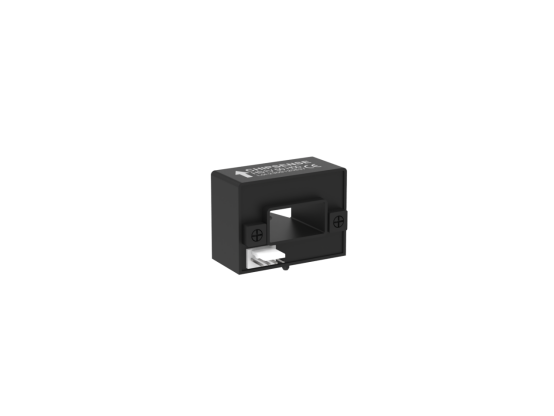

The HS1V series is a mature Hall open-loop current sensor product independently developed by CHIPSENSE, 100% domestically produced, enabling local substitution. It is compatible with major international sensor brands, with a range from 50A to 600A, covering common three-phase motor loads. The accuracy is ±1%, meeting the common condition monitoring needs of motors. It operates at a supply voltage of ±12V to ±15V, outputs an analog voltage signal, and is compatible with PLC/DCS systems, facilitating digital upgrades of equipment. The features of CHIPSENSE HS1V current sensor’s insulation withstand voltage of 3.6kV (AC) and 6.6kV (transient), complying with industrial standards such as EN50178 and IEC61010-1, ensuring control-side safety. The installation method of CHIPSENSE is perforated, requiring no power-off busbar modifications, and its compact size of only 3x4x3 cm makes it convenient for upgrading older equipment without reserved interfaces. CHIPSENSE current sensors must be modified and upgraded to meet customer requirements.

Typical application scenarios:Inverters driving motors: CHIPSENSE HS1V Hall open-loop current sensors are mainly used for current detection, protection control, and system optimization in systems where inverters drive motors.

1.Current Detection and Feedback- Accurate Measurement:

Real-time detection of the inverter output three-phase current (U, V, W) through the Hall effect provides feedback signals for torque current (Iq) and excitation current (Id) for Field-Oriented Control (FOC), ensuring efficient motor operation.

Wide Frequency Response: Capable of capturing high-frequency current harmonics under PWM modulation, meeting the high switching frequency requirements of modern inverters.

2.Protective Function

Real-time monitoring of operating current, detecting overloads, stall conditions, and other anomalies to trigger the inverter's protection mechanisms, preventing damage to power devices like IGBTs. CHIPSENSE current sensor must ensure this.

3.System Optimization

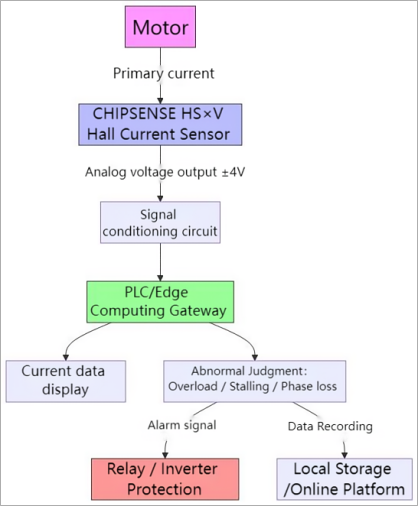

Optimize inverter output through precise current feedback, reducing motor heating and energy consumption, thus improving energy efficiency. Continuous monitoring of current waveforms can identify anomalies such as winding short circuits and inverter switching failures, providing a basis for fault diagnosis.System diagram for retrofitting old motors with current sensors:

Application Case:

A hardware processing factory with 15 old stamping machines uses frequency converters produced in 2012, which lack current feedback functionality.

Upgrade Plan:

Install CHIPSENSE HS1V current sensors on the output side of the frequency converters, connect the current signals to the local edge acquisition box, and upload the data to the lightweight MES system.

Actual Value:

Monitor in real time for overloads (such as mold jamming)

Identify periods of no-load/light-load to optimize production scheduling

Record start-stop cycles and inrush currents to predict the lifespan of contactors

Reduce unplanned downtime by 30% after using CHIPSENSE current sensors.

Conclusion

For the renovation of old motors, Hall open-loop current sensors are recommended, especially domestic sensors. Their low cost, ease of installation, and electrical isolation features perfectly match renovation needs. For small and medium-sized enterprises, starting with 'visible current' is the first step towards digitalization. CHIPSENSE current sensors are also keep adapting to the changes of the times.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806