In recent years, our country's energy storage has developed rapidly. According to the statistics of the National Energy Administration, in the first half of this year, the installed scale of new energy storage in the country reached 94.91 million kW/222 million kWh, an increase of about 29% from the end of 2024. However, the average energy conversion efficiency of the current energy storage system is 85%, which is lower than the "Energy Storage Industry Development Plan" requiring the energy storage system efficiency to reach more than 90%. The loss is mainly due to inaccurate battery management, excessive thermal management, and inverter harmonics. This article talks about how to help energy storage systems improve efficiency through ASIC current sensors. CHIPSENSE current sensor is one of them.

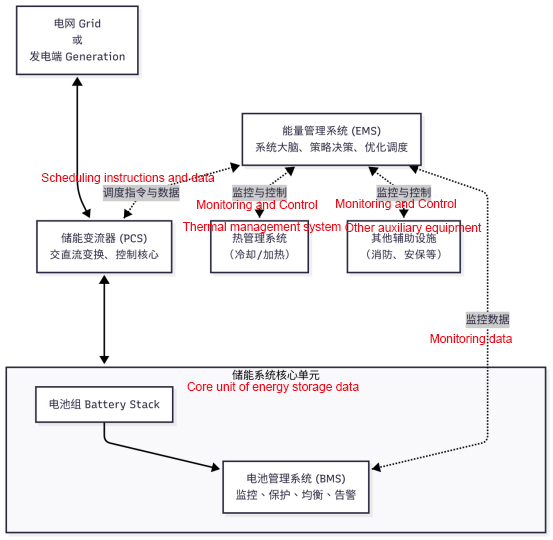

Overview of energy storage systems

Energy storage system is the core component of modern energy system. By storing and releasing electric energy on demand, it realizes efficient use of energy and stable operation of the power grid. According to the application scenario, energy storage systems are mainly divided into grid-side energy storage, user-side energy storage and generation-side energy storage. They are widely used in renewable energy grid connection, peak-to-valley regulation, backup power supply and microgrid. CHIPSENSE current sensors also have many applications.

1. The basic structure of an energy storage system

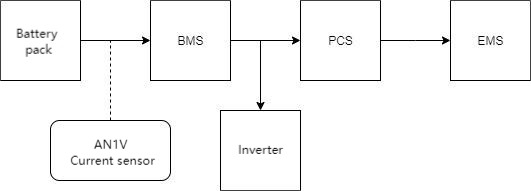

A typical energy storage system is mainly composed of the following components:

Battery pack: Core energy storage unit, usually using lithium-ion batteries, lead-acid batteries, or flow batteries.

BMS (Battery Management System): responsible for battery monitoring, protection, and balance management.

PCS (Energy Conversion System): includes inverters and converters to achieve AC/DC conversion.

EMS (Energy Management System): Overall scheduling and optimization of energy flow.

Monitoring sensor: real-time acquisition of current, voltage, temperature and other key data.

Figure 1: Basic structure of an energy storage system

The key role of current detection in energy storage systems

Current detection is one of the most basic and critical links in an energy storage system. Accurate current data directly affects the SOC (State of Charge) estimation, SOH (State of Health) evaluation and system security protection of BMS. CHIPSENSE is the same as all of them.

At present, there are mainly the following current detection solutions on the market.

| Detection solution | Response time | Accuracy | Temperature drift | Cost | Applications |

| Shunt | <1μs | ±0.5% | High | low | Low voltage low current system |

| Traditional Hall Sensor | >10μs | ±1% | ±3% | middle | General industrial applications |

| Closed Loop Hall Sensor | 5μs | ±0.5% | ±1% | high | High-precision demand scenario |

| AN1V ASIC current sensor | <2.5μs | ±1% | ±1.5% | middle | Efficient energy storage system |

Overview of CHIPSENSE AN1V series current sensors:

CHIPSENSE AN1V series current sensor is a fully upgraded high-performance miniature Hall current sensor product based on the Hall principle independently. CHIPSENSE adopts ASIC technology and is specially designed for high-precision current detection. It is 100% domestic and realizes domestic replacement. The current sensor of CHIPSENSE has the characteristics of primary and secondary insulation, no insertion loss, small size, high consistency and high reliability, and is widely used in energy storage systems, battery management, UPS, frequency converters, wind energy converters and other fields.The application of CHIPSENSE current sensor is more than that.

1.Product model and specifications

| Model | Measuring range(A) | Typical Sensitivity (mV/A) | Operating temperature range(°C) | Applications |

| AN1V 50 PB512 | ±50 | 40 | -40~150 | Low power energy storage、BMS |

| AN1V 100 PB512 | ±100 | 20 | -40~150 | Medium power energy storage、UPS |

| AN1V 150 PB512 | ±150 | 13.33 | -40~125 | Frequency converter, welding machine power supply |

| AN1V 200 PB512 | ±200 | 10 | -40~85 | High power energy storage, wind energy converter |

| AN1V 250 PB512 | ±250 | 8 | -40~85 | Industrial grade inverter |

| AN1V 300 PB512 | ±300 | 6.66 | -40~85 | High power motor drive |

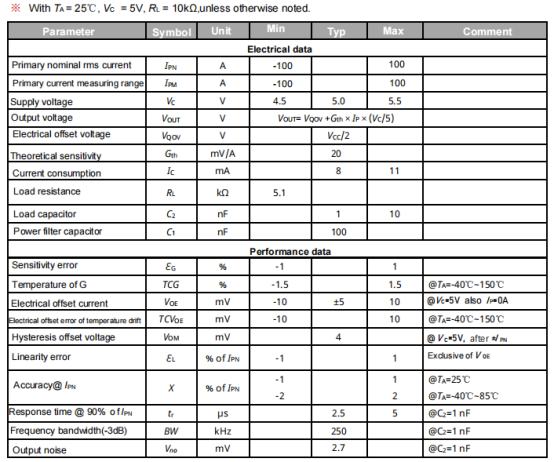

2.Core technical parameters

Electrical characteristics (take AN1V 100 PB512 Current Sensor of CHIPSENSE as an example)

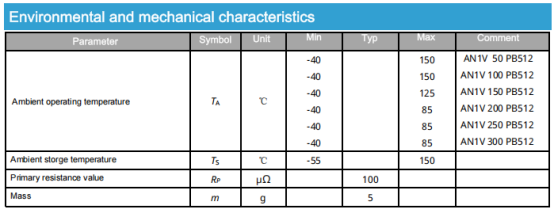

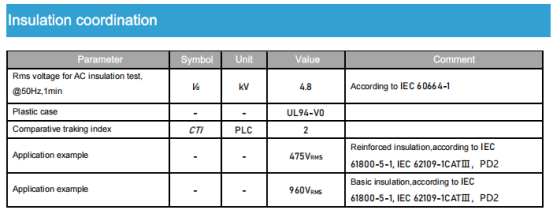

Environmental and safety features

Selection guide

Select the current sensor model of CHIPSENSE according to the current range

Low power (< 50A): CHIPSENSE AN1V 50 PB512 current sensor

Medium power (50~ 150A): CHIPSENSE AN1V 100/150 PB512 current sensor

High power (> 150A): CHIPSENSE AN1V 200/250/300 PB512 current sensor

Figure 2: Application location of CHIPSENSE AN1V current sensors in energy storage systems

| Indicator | Before optimization | After optimization | Improvement range |

| SOC estimation error | ±10% | ±2% | 80% reduction |

| System efficiency | 85% | 92% | 7% increase |

| Heat dissipation energy consumption | 8% | 5% | 37.5% decrease |

| Battery cycle life | 3000 times | 3500 times | Extend by 16.7% |

The basis for comparing actual project data

1. 80% reduction in SOC estimation error

Basis:

The accuracy of the CHIPSENSEAN1V 100 PB512 current sensor is ± 1% at 25 ° C and ± 2% at -40 to 85 ° C.

Conventional Hall sensors typically have an accuracy of ± 3% or less, resulting in SOC estimation errors of up to ± 10% for BMS.

With AN1V current sensor from CHIPSENSE, the SOC estimation error can be reduced to ± 2% (based on the combined effect of sensor accuracy and BMS algorithm).

Calculate:

Original error: ± 10%

Error after optimization: ± 2%

Improvement: (10% - 2%)/10% = 80%

2.System efficiency increased by 7%

Basis:

CHIPSENSE AN1V's high-precision current detection and fast response time (< 2.5μs) enable optimized battery equalization and charge-discharge management for BMS.

According to industry experience, accurate current monitoring can increase the energy conversion efficiency of energy storage systems from 85% to 90% to 92%.

Combined with CHIPSENSE current sensor of AN1V's low temperature drift (± 0.2%) and low noise (2.7mV), further reducing energy loss.

Calculate:

Original efficiency: 85%

Optimized efficiency: 92%

Improvement: 92% - 85% = 7%

3. Reduce heat dissipation energy consumption by 37.5%

Basis:

The high-precision current data of CHIPSENSE AN1V current sensor can help the BMS to more accurately control the charging and discharging process of the battery, reducing overcharge and over-discharge.

By optimizing thermal management strategies, such as dynamically adjusting heat dissipation power, heat dissipation energy consumption can be reduced from 8% to 5%.

Calculate:

Original heat dissipation energy consumption: 8%

Optimized heat dissipation energy consumption: 5%

Improvement: (8% - 5%)/8% = 37.5%

4. Extend battery cycle life by 16.7%

Basis:

CHIPSENSE AN1V's high-precision current monitoring and low temperature drift can reduce battery overcharge and over-discharge, thus prolonging battery cycle life.

According to industry data, accurate current management can increase the battery's cycle life from 3,000 to 3,500 cycles.

Calculate:

Original cycle life: 3000 cycles

Optimized cycle life: 3500 cycles

Range of improvement: (3500 - 3000)/3000 = 16.7%

According to this case, it can be seen that the CHIPSENSE current sensor is a good choice.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806