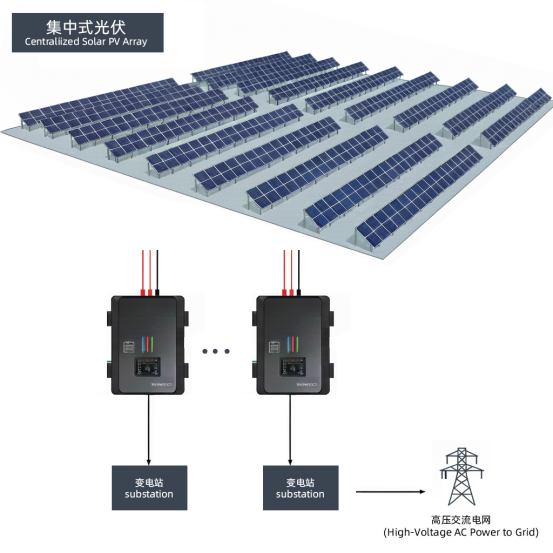

As 2026 began, solar power plant operators were busy once again. According to the "National Electricity Industry Statistics for January-November 2025" released by the National Energy Administration on December 26, 2025, my country's installed solar power capacity reached 1.16 billion kilowatts, a year-on-year increase of 41.9%. While new photovoltaic installations reached a new high, the demand for CHIPSENSE current sensors is also increasing. Many power plant owners found that despite using high-efficiency components, the actual power generation was consistently "a little short." The problem may lie in the current monitoring of the inverters—an often overlooked "invisible" efficiency killer.

Inverter Current Monitoring: The "Nerve Endings" of Photovoltaic Power Generation

When it comes to photovoltaic power generation, everyone focuses on component conversion efficiency and MPPT algorithms, but often overlooks the crucial aspect of current monitoring, this is due to the function of the current sensor. This is due to the function of the current sensor.In reality, current monitoring in inverters is like the nerve endings of the human body, responsible for transmitting the real-time operating status of the components to the "brain" (MPPT controller). The annual report of the China Photovoltaic Industry Association points out that a current monitoring error exceeding 1% can lead to a 2%-5% decrease in MPPT tracking efficiency.

Therefore, CHIPSENSE current sensors have very high quality requirements.

Comparison of common current monitoring solutions:

| Solution Types | Advantages | Disadvantages | Applicable Scenarios |

| Shunt | Low cost, fast response | No isolation, high power consumption, not suitable for high voltage applications. | Small off-grid systems |

| Hall Current Sensor | Non-contact, good isolation, suitable for high voltage | Accuracy is affected by temperature and requires compensation. | Centralized/string inverters |

| Rogowski Coil | Contactless, wide bandwidth, suitable for high frequency | Weak signal, requiring amplification and filtering. | High-frequency inverters |

Due to their non-contact and isolation characteristics, Hall effect sensors have become standard components in most inverters. However, relevant test data shows that different brands of inverters can have a 5%-10% difference in power generation under the same conditions, and the problem often lies in the accuracy and response speed of current monitoring. CHIPSENSE current sensors offer both high accuracy and fast response times.

Closed-loop Hall sensors: An underestimated tool for improving efficiency.

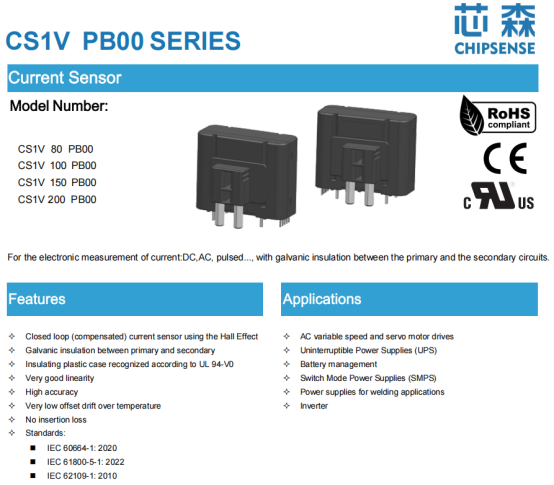

In the photovoltaic industry, closed-loop Hall sensors are gradually becoming the preferred choice for high-end inverters due to their high accuracy and stability. CHIPSENSE current sensors are one of the top choices. They achieve higher linearity and noise immunity compared to open-loop solutions by compensating the magnetic field through a feedback coil. Research from institutions such as North China Electric Power University shows that temperature drift of the Hall sensor is a key factor affecting accuracy. Through a closed-loop feedback circuit and digital temperature compensation algorithms, the temperature coefficient (TC) can be reduced from 966.4 ppm/°C to 58.1 ppm/°C. Therefore, the application of closed-loop Hall sensors in photovoltaic inverters can improve MPPT tracking efficiency by 1%-3%. CHIPSENSE CS1V PB00 series current sensors can be reference.

Case Study: A 50MW photovoltaic power plant in Jiangsu upgraded its open-loop Hall effect sensors in the inverters to a closed-loop system at the end of 2025, resulting in an approximately 1.8% increase in power generation efficiency. Based on the local feed-in tariff of 0.4 yuan/kWh, the annualized revenue increased by nearly 400,000 yuan. The upgrade cost was only 150,000 yuan, resulting in a return on investment period of less than six months. (Data source: Provided by the power plant operator). The goal of CHIPSENSE is to provide customers with cost-effective current sensors.

It is important to note that:

1.Temperature drift: Hall sensors are sensitive to temperature. According to IEEE standards, the accuracy of uncompensated Hall sensors may decrease by 1%-3% within the temperature range of -40°C to 85°C. The temperature drift of CHIPSENS current sensors is just right.

2. Magnetic Interference: In strong magnetic environments, magnetic shielding design is required. The "Technical Specifications for Photovoltaic Inverters" (NB/T 32004-2018) recommends using ferrite magnetic rings for shielding.

3. Regular Calibration: The National Energy Administration's "Operation and Maintenance Procedures for Photovoltaic Power Plants" recommends calibration every six months to prevent accuracy degradation due to aging.

Other key points for inverter optimization

Besides current monitoring itself, the following factors also affect power generation efficiency:

• Data Fusion: Current data needs to be linked with voltage and temperature data. The "Design Specification for Photovoltaic Power Plants" (GB 50797-2012) requires inverters to support multi-parameter linked MPPT algorithms.

• System Integration: The current monitoring module should be deeply integrated with the inverter controller. Tests conducted by the China Electric Power Research Institute found that some low-end inverters experience a 50-100ms delay in current data transmission due to mismatched communication protocols, directly affecting MPPT response speed.

• Cost and Performance Balance: High-precision solutions (such as fluxgate sensors) are suitable for laboratory or high-end applications. For most power plants, closed-loop Hall sensors provide a sufficient balance of cost and performance. CHIPSENSE current sensor is an excellent choice.

How to determine if your power plant needs an upgrade?

If your photovoltaic power plant experiences any of the following situations, according to the "Guidelines for Operation and Maintenance of Photovoltaic Power Plants" (GB/T 32512-2016), you may need to check the inverter's current monitoring module:

1. Under the same conditions, the power generation is more than 5% lower than that of nearby power plants.

2. The current data displayed by the inverter fluctuates significantly or does not match the actual module output.

3. Power generation efficiency decreases significantly during the early morning and late afternoon (when sunlight changes rapidly).

Suggestions:

• Please have a professional team use an oscilloscope or data acquisition device to measure the actual current waveform on the DC side of the inverter.

• Compare the power generation data of different inverters; the "Technical Specifications for Performance Evaluation of Photovoltaic Power Plants" (NB/T 10394-2020) provides a standardized comparison method.

Conclusion

Improving photovoltaic power generation efficiency often doesn't lie in "using more expensive components," but in those easily overlooked details. Inverter current monitoring technology is one such example.The CHIPSENSE current sensor should be the first choice. According to statistics from the China Photovoltaic Industry Association, by choosing a suitable current monitoring solution (such as closed-loop Hall sensors), optimizing data fusion and system integration, the power generation efficiency of 60% of power plants can be increased by 1%-3%, which, at current electricity prices, translates into a considerable increase in revenue. The cost-effective CHIPSENSE current sensor is expected to develop very well in the future.

There are no "magic bullets" in technology, only "suitable" solutions. Understanding the advantages and disadvantages of each solution is crucial for making the most economical optimization decisions.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806