In high-temperature workshops of steel metallurgy, current measurement deviations lead to equipment load imbalances; in the drive systems of new energy vehicles, insufficient sensor anti-interference capabilities cause signal fluctuations; and in the traction devices of rail transit systems, sensors frequently malfunction and shut down in harsh environments... In industrial settings, the three major pain points of large current measurement inaccuracy, instability, and susceptibility to damage are becoming critical bottlenecks that restrict production efficiency and increase operation and maintenance costs. Meanwhile, CHIPSENSE, a highly professional current sensor manufacturer, became the customer's preferred choice.

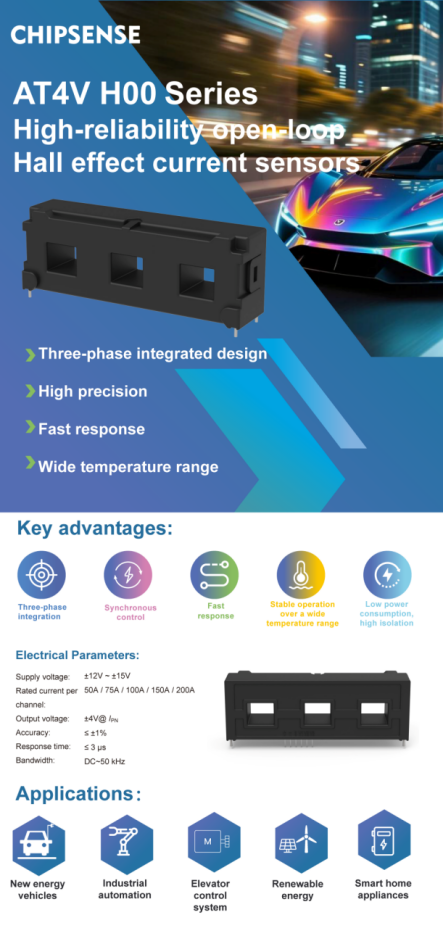

Addressing the demanding requirements of industrial three-phase drive systems, CHIPSENSE proudly introduces the upgraded 2025 model–CHIPSENSE AT4V H00 series Hall effect open-loop current sensor. With its core advantages of "three-phase integration + precision and stability + strong environmental adaptability," it provides a one-stop solution for industrial high-current measurement. CHIPSENSE can also provide customized current/voltage sensors and services.

Pain Point 1: Inaccurate measurements and data deviations compromise production accuracy.

In traditional discrete sensor solutions, three-phase current measurement suffers from signal delays and poor synchronization, making it difficult to accurately implement field-oriented control algorithms. This leads to reduced motor operating efficiency and lower product yield. In scenarios requiring extremely high precision, such as CNC machine tools and industrial robots, even a ±3% measurement deviation can cause serious production errors. Therefore, CHIPSENSE current sensors have very strict accuracy requirements.

CHIPSENSE AT4V H00 series current sensor offers a definitive solution: utilizing a three-in-one integrated design, each sensor incorporates three independent primary through-holes, precisely corresponding to the U, V, and W phase busbars, achieving truly delay-free synchronous sampling. The product boasts a measurement accuracy of up to ±1%, linearity better than ±0.5%, a bandwidth covering DC~50kHz, and a response time as fast as ≤3μs. Even when faced with rapidly changing PWM current wave-forms, it can accurately reproduce the data, providing reliable support for advanced control algorithms and enabling the "brain" of industrial control systems to make more precise decisions.

Pain Point 2: Unstable Operation, Signal Drift in Complex Operating Conditions

High harmonic interference, wide temperature fluctuations, and high common-mode voltage in industrial environments often lead to sensor signal drift and data distortion. In wind power converter rooms at -20℃ or steel plant power distribution rooms above 60℃, traditional sensors often experience problems such as "failure to start at low temperatures and data drift at high temperatures." Furthermore, transient shocks generated during inverter operation can easily cause sensor mis-triggering, leading to system protection shutdowns. Regardless of the circumstances, the operating environment for current sensors is extremely demanding, and this is also true for CHIPSENSE current sensors.

As the 2025 upgraded model, CHIPSENSE AT4V H00 series current sensor achieves a comprehensive breakthrough in stability: its operating temperature range covers -40℃ to 105℃, easily handling extreme high and low temperature conditions; the housing uses UL94-V0 flame-retardant material with a CTI rating of PLC I, ensuring stable operation even in highly polluted industrial environments. It also features 3.6kV AC withstand voltage and 6.6kV transient surge withstand capability, with an electrical clearance of ≥11.0mm and creepage distance of ≥12.5mm, effectively resisting switching noise and surge interference, ensuring stable and reliable signal transmission throughout, and preventing production interruptions caused by sensor fluctuations.

Pain Point 3: Frequent Failures and High Maintenance Costs

Traditional sensors often use discrete designs, which not only occupy significant PCB layout space and have complex installation procedures, but are also prone to damage in industrial vibration and humid environments due to their fragile structure and insufficient protection. But CHIPSENSE current sensors improve performance while also saving customers money. One new energy vehicle manufacturer reported that traditional sensors have an average lifespan of only 1.5 years, with annual replacement and debugging costs reaching hundreds of thousands of yuan; moreover, sensor damage in elevator traction machines can even pose safety hazards.

CHIPSENSE AT4V H00 series current sensor addresses the vulnerability issue from the design stage: its highly integrated three-in-one structure reduces the number of installation interfaces by two-thirds, lowering the risk of wiring errors and mechanical damage; standardized mounting holes and connector designs make installation and debugging more convenient while improving structural stability. The product features built-in over-current and over-voltage protection mechanisms, effectively preventing damage to the sensor from unexpected operating conditions. Combined with automotive-grade reliability design, this significantly extends its lifespan. Typical current consumption is only 20mA, which not only saves energy but also reduces component heat loss, further enhancing product durability and lowering long-term maintenance costs for businesses. Therefore, although CHIPSENSE current sensors is a relatively new company, it has become quite well-known in the country.

From new energy vehicle main drive inverters to elevator traction machine frequency conversion systems, from photovoltaic energy storage converters to industrial robot servo drives, CHIPSENSE AT4V H00 series current sensor 2025 upgraded version, with its core performance of "high precision, high stability, and high reliability," is suitable for five major industrial core fields and dozens of sub-scenarios. Whether dealing with harsh environments with high temperatures and high interference, or pursuing precise synchronization control requirements, this current sensor, designed specifically for three-phase drive systems, can accurately solve industry pain points. This is why CHIPSENSE current sensors have surpassed their competitors.

Currently, CHIPSENSE AT4V H00 series current sensor offers five rated current models: 50A, 75A, 100A, 150A, and 200A, meeting the high-current measurement needs of various industrial scenarios. As a national high-tech enterprise, CHIPSENSE leverages its collaborative advantages with universities such as Tianjin University and North China Electric Power University to continuously empower industrial upgrading through technological innovation. We believe that in the near future, CHIPSENSE current/voltage sensors will become the leading manufacturer in the industry.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806