According to data from the Chinese Renewable Energy Society: offshore wind power tenders in the first half of 2025 increased by 41% year-on-year. Industry trend tracking indicates: during the first half of 2025, newly installed onshore wind power capacity connected to the grid nationwide reached 48.90GW, representing a 95.52% year-on-year increase; newly installed offshore wind power capacity connected to the grid reached 2.49GW, marking a 200.00% year-on-year increase. Cumulative onshore wind power capacity reached 528GW, marking a 22.89% year-on-year increase. This signifies not only a new phase in clean energy development but also presents fresh challenges to grid stability from large-scale wind power integration. As wind turbine unit capacities continue to rise, current sensors–often overlooked as minor components–are becoming critical to ensuring system reliability. CHIPSENSE current sensor is one of them.

In recent years, the wind power industry has transformed from a "rush for installation" to a "steady growth" phase. This year's increase has once again exceeded expectations, mainly due to three reasons:

1.Policy drive: During the concluding phase of the 14th Five-Year Plan, many regions are concentrating on advancing wind power projects.

2.Industrial upgrade: Large onshore and offshore wind turbines over 10MW are gradually becoming the mainstream.

3.Green transformation: The power system's reliance on clean energy continues to rise.

But opportunities come with challenges. When large wind turbines are connected to the grid, the output current increases exponentially, which also heightens the risk of impacts and fluctuations on the power grid. If current monitoring and control are not precise enough, it may lead to grid instability, or even trigger protective misoperations or equipment damage.

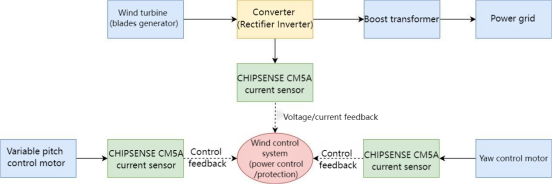

An electrical system of a wind turbine typically includes:

Generator (converts wind energy into electrical energy)

Inverter (rectifies and inverts to achieve AC/DC conversion)

Boost transformer (increases voltage to grid box level)

Control system (real-time adjustment of power and protection)

and auxiliary pitch and yaw motors

In these processes, the current sensor acts like 'eyes', responsible for monitoring the magnitude and fluctuations of the current, and transmitting the data in real time to the control system.

Figure 1: Wind diagram of the fan electrical system

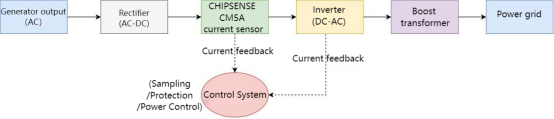

The electrical energy generated by the wind turbine is first converted to direct current by the rectifier, and then output to the grid through the inverter. The current on the DC bus not only reflects the real-time output of the generator but is also a key parameter for the grid-connected inverter's power control and protection.Therefore, current sensors are often installed at the DC bus, Taking on responsibilities:

• Real-time current sampling → Provides precise control basis;

• Fault monitoring → Abnormal current triggers protection;

• Data feedback → Supports Maximum Power Point Tracking (MPPT).

Figure 2: Schematic diagram of DC bus current detection (Typical installatio for CHIPSENSE CM5A current sensor)

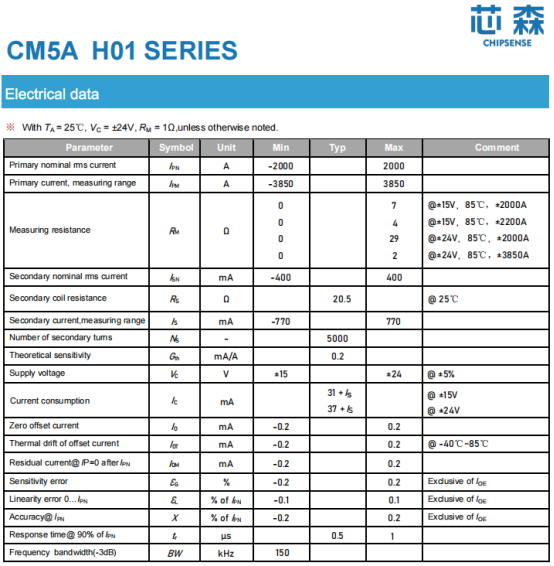

Among many current sensors, CHIPSENSE CM5A series current sensor is widely used in large wind turbine systems due to its wide measurement range, high precision, and high cost-performance ratio as a domestic alternative. Its features include:

Wide measurement range: Rated from 100-2000A, can measure up to ±3850A, covering the needs of 10MW level wind turbines.

High insulation capability: Withstand voltage of 6kV and impulse voltage of 23kV, suitable for high-voltage grid connection environments.

High precision, low drift: Based on closed-loop Hall principle, ensuring stable data under long-term operation.

Fast response: 0.5-1µs, can provide instant feedback during grid fluctuations to prevent accident escalation.

Application scenarios: Inverter for wind turbines, wind energy frequency converters, auxiliary motor control, energy storage support, etc.

It can be said that CHIPSENSE CM5A current sensor plays the role of a 'goalkeeper' in wind turbines: it does not generate electricity directly, but ensures the safety of the entire system through precise current monitoring. CHIPSENSE current sensor is not only a good choice for compliance but also a solid guarantee of customers.

In today's world, where the proportion of new energy is continuously increasing, the importance of current sensors is being re-recognized. CHIPSENSE current sensor also play an important role in it.

For the power grid: reduce grid impact and improve the stability of the power system.

For wind farms: improve operational efficiency, extend equipment lifespan, and reduce total life-cycle costs.

For the energy transition: providing fundamental support for large-scale renewable energy consumption.

Conclusion

The rapid increase in wind power installation capacity this year is great news, but it requires more technical support behind it. Large current sensors like CHIPSENSE CM5A current sensor are indispensable 'invisible heroes' in the process of integrating wind energy into the grid. They silently monitor every fluctuation in current, CHIPSENSE current sensor allowing clean energy to enter households more stably and safely.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806