In modern railway transportation, whether it is the "Fuxing" high-speed rail with a speed of 350 kilometers per hour or the "Harmony" high-speed train with a speed of 250 kilometers per hour, it is mainly driven by electricity. The locomotive traction system is the core power system to ensure the efficient and safe operation of the train. In the complex locomotive traction system, it is necessary to monitor the current of the traction motor in real time to provide accurate feedback signals for the control system to ensure the stable output of the traction force, overcurrent protection and energy efficiency optimization, etc., to ensure the stable operation of the system. This paper will combine several common current detection schemes and analyze CHIPSENSE CM4A current sensor of it’s typical application examples in the locomotive traction system.

The vast majority of high-speed trains and bullet trains, such as Harmony and Fuxing, rely on external power systems to provide their power sources: the "pantograph" on the roof is in continuous contact with the catenary wires, introducing high-voltage electricity into the train, converting it into three-phase alternating current driving the motor through traction transformers, converters and other equipment, and finally driving the wheels through the traction motor.

Notes: Some trains may use a mix of electric and internal combustion engines to accommodate complex circuits.

Current Detection Requirements in Locomotive Traction System

A locomotive traction system usually consists of a converter, an inverter, and a traction motor. The traction current has the following characteristics:

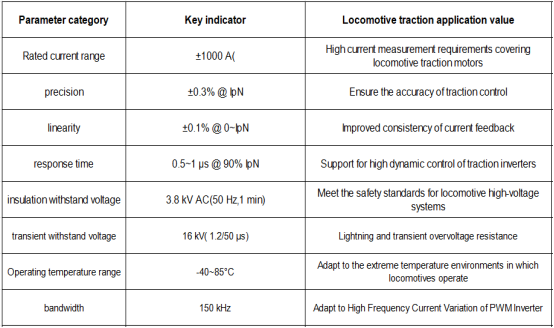

Therefore, current sensors used in locomotive traction systems generally require high accuracy, wide measurement range, and fast response characteristics, while meeting the requirements of electrical insulation and environmental resistance. The current sensor of CHIPSENSE will meet this needs.

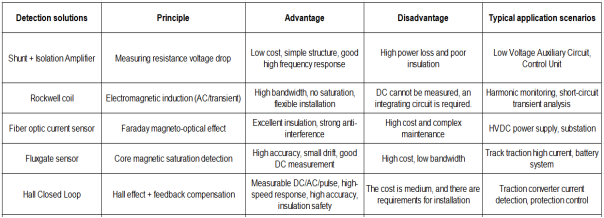

Common Current Detection Scheme of Locomotive Traction System

The current detection schemes of the locomotive traction system include shunt, Roche coil, fiber optic current sensor, fluxgate, hall closed-loop current sensor, etc. They have their own characteristics in terms of performance, application scenarios and cost:

In the actual locomotive traction system, it is often not a single solution, but a combination according to the functional requirements of different application scenarios and links.

Application Example of Hall Closed Loop Current Sensor in Locomotive Traction System

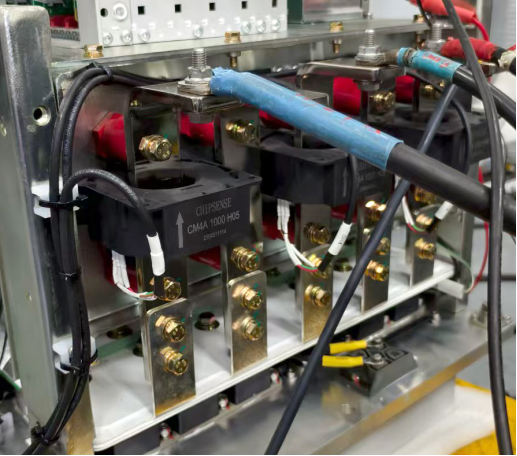

As can be seen from the application diagram, CM4A current sensor of CHIPSENSE is installed on the DC bus or AC output of the traction converter. The primary bus is fully filled with the via of the sensor, and the output wiring harness of the sensor is connected to the control system to provide real-time current feedback signals to the system. Its typical functions include:

Current Feedback in Traction Inverters: CHIPSENSE CM4A current sensors monitor the phase current of the traction motor in real time, providing accurate current feedback to the Control Unit of the inverter, real-time adjustment of PWM modulation, and precise motor control. Through closed-loop control, traction output can be optimized, over-current protection can be achieved, and fault diagnosis can be achieved.

Energy feedback in regenerative braking systems: In regenerative braking mode, CHIPSENSE CM4A current sensors accurately measure the feedback current to ensure the efficiency and stability of energy recovery, preventing excessive feedback current from overloading the power grid or energy storage devices.

Protection function: When the traction current is abnormally high (e.g. short circuit or out of control), the sensor signal can trigger a protection mechanism to avoid damage to the power device.

Condition monitoring and fault diagnosis: Through real-time acquisition of current waveforms, fault recording and health monitoring systems can be assisted to achieve predictive maintenance.

Current monitoring of auxiliary systems: CHIPSENSE CM4A current sensor can also be used in auxiliary systems of locomotives, such as auxiliary inverters and battery management systems, to provide stable power monitoring for air conditioners, lighting, and other equipment.

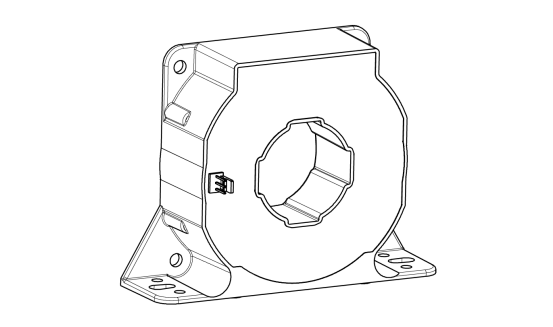

Introduction to Hall Closed Loop Current Sensor CM4A 1000 H05 of CHIPSENSE

CM4A series current sensors are independently developed by CHIPSENSE. They use Hall closed-loop (compensation) principle to detect the magnetic field generated by the primary current through Hall components, and generate compensation current through the secondary coil to achieve electrical isolation between the primary and secondary sides. The same is true for CHIPSENSE’s other current sensors.

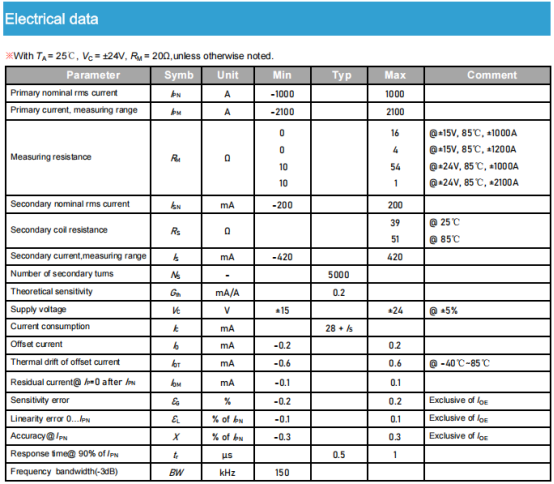

Core technical parameters:

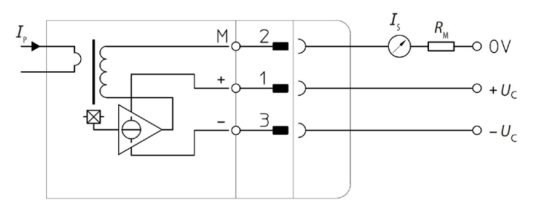

Typical application connection diagram

Summary

In the locomotive traction system, the Hall closed-loop current sensor provides a reliable current detection method for traction motor control and system protection through high precision, fast response and good insulation characteristics. Although it is not a universal solution, it is indeed a mature and reliable technical path in the railway traction scenario of high voltage and high current. From the customer's feedback, it can be seen that CHIPSENSE current sensor is a good choice.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806