In the inverters of photovoltaic power stations and the battery cabinets of energy storage systems, the silent working Hall current sensors are safeguarding the safety and efficiency of every green kilowatt-hour with a precision of 0.5%. The high-quality development of the new energy industry has quietly entered the era of precise measurement.

In the maintenance room of photovoltaic power stations, engineer Wang is frowning as he stares at the suddenly fluctuating data curve on the monitoring screen. "The DC current of Inverter No. 3 in Zone C is abnormally fluctuating, exceeding the safety threshold by 5%."

He quickly retrieved historical data and found that this anomaly had started intermittently three days ago, each time lasting less than 2 seconds. The conventional monitoring equipment could hardly capture it.

However, with the new monitoring system equipped with high-precision CHIPSENSE Hall current sensors, these subtle abnormalities were nowhere to hide. After on-site investigation, the problem was ultimately located to a slight corrosion of the connection terminals of a group of photovoltaic panels. This seemingly minor fault, if not detected in time, could potentially cause thermal spot effects, leading to component damage or even fire risks over the long term.

1. Industry Turning Point, New Energy Electricity Enters the Era of Precise Measurement

The Chinese new energy electricity industry is undergoing a profound transformation. The latest industry data shows that it is expected that by 2026, the installed capacity of solar power generation will historically exceed that of coal power for the first time, and the combined installed capacity of wind and solar power is expected to account for about half of the total installed capacity.

The comprehensive implementation of the power market trading mechanism is underway, and new energy electricity no longer enjoys the preferential treatment of "guaranteed quantity and guaranteed price". The value of each kilowatt-hour of electricity needs to be realized through market transactions.

In this context, the industry focus has shifted from the "expansion" stage of merely pursuing installation scale to a new stage that emphasizes "multi-energy complementarity, source-grid coordination, and integration" for high-quality development.

This transformation has placed unprecedented precision requirements on the monitoring and control of the new energy power system.

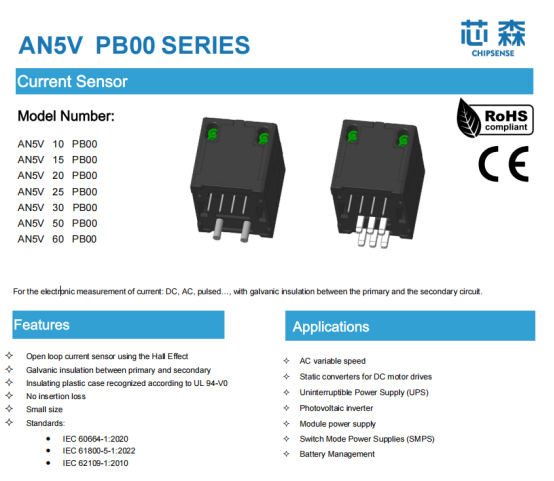

Traditional current measurement technologies such as shunts have limitations such as insertion loss and insufficient electrical isolation. They are inadequate in today's high-voltage and high-power new energy applications. However, CHIPSENSE current sensors based on the Hall effect, with their non-contact measurement, high precision, wide frequency response, and excellent isolation characteristics, are becoming the key components for current monitoring in the new energy system.

2. Technical Principle: How the Hall Effect Achieves Precise Current Sensing

The core principle of CHIPSENSE Hall current sensor is the Hall effect in electromagnetism. When current flows through a conductor, a magnetic field is generated around it, and the strength of this magnetic field is proportional to the current magnitude.

The Hall element is placed in the magnetic field, and a potential difference - the Hall voltage - is generated in the direction perpendicular to the current and the magnetic field.

By accurately measuring this voltage, the actual value of the measured current can be indirectly obtained. The Hall effect converts current measurement into magnetic field measurement, achieving complete electrical isolation between the measured circuit and the measurement circuit, which is its most significant technical advantage.

In new energy application scenarios, CHIPSENSE Hall current sensors have derived various technical routes. Open-loop Hall sensors have a simple structure and low cost, directly sensing the magnetic field through the Hall element; closed-loop Hall sensors use a feedback coil to generate a counter-magnetic field, achieving higher accuracy and linearity.

In recent years, integrated Hall current sensors integrate the Hall element, signal conditioning circuit, and temperature compensation function on a single chip, significantly simplifying system design.

In actual new energy systems, current measurement faces many challenges: a system voltage of up to 1500V on the DC side, complex harmonic components on the AC side, wide temperature range (-40°C to +85°C), and strong electromagnetic interference environment.

The core advantage of CHIPSENSE Hall current sensor lies in its inherent electrical isolation capability. It can complete the measurement without physical contact with the measured conductor, completely eliminating the insertion loss and safety hazards of traditional shunts.

3. Application Scenarios: The "Current Eye" of the New Energy System

In photovoltaic power generation systems, CHIPSENSE Hall current sensors play multiple key roles. On the DC side, they monitor the output current of each string of photovoltaic modules in real time, providing precise data input for maximum power point tracking.

The new sensors installed in the power station where Mr. Wang works can detect current imbalances as low as 0.1%, helping the maintenance team promptly identify string faults, shading, or dust accumulation problems.

On the AC side, the output current monitoring of grid-connected inverters is more critical. Power quality standards require that the total harmonic distortion rate of grid-connected current be below 5%. High-precision Hall sensors can accurately capture each harmonic component, providing feedback for the inverter control algorithm.

In wind farms, CHIPSENSE Hall current sensors are also widely used. The rotor-side converter of doubly-fed wind turbines requires precise control of rotor current to achieve maximum wind energy capture; the full-power converter of direct-drive permanent magnet synchronous generators needs to monitor stator current to ensure stable grid connection.

Facing random fluctuations in wind speed, sensors must have extremely fast response speed (typically below 1 microsecond) and wide frequency band characteristics to keep up with the dynamic requirements of the control system.

Energy storage systems are another important application area for Hall current sensors. In battery management systems, sensors precisely measure charging and discharging currents, providing key input for state of charge estimation, with errors typically controlled within 0.5%.

The latest integrated sensors can even directly output digital signals, communicating with the main controller through I2C or SPI interfaces, significantly simplifying system wiring. Wang's team recently verified this advantage in a photovoltaic storage integrated project: After adopting digital output Hall sensors, the wiring inside the battery cabinet was reduced by 40%, and the system reliability significantly improved.

4. Technical Requirements, Special Challenges in New Energy Scenarios and Their Solutions

New energy applications have imposed strict technical requirements on Hall current sensors. In terms of accuracy, grid-connected metering needs to reach 0.5 class or even 0.2 class accuracy, while protective purposes focus more on rapid response and overload capacity.

Temperature stability is particularly crucial. The sensor must maintain accuracy within the wide temperature range of -40°C to +85°C, and an internal temperature compensation algorithm becomes a necessary function.

Electrical characteristics-wise, the high-voltage environment of the new energy system requires the sensor to have sufficient isolation voltage (typically 2.5kV to 6kV). Rapid response capability is also important, especially for applications requiring real-time control, where the sensor bandwidth needs to cover from DC to hundreds of kHz.

Electromagnetic compatibility is a severe test for on-site applications. Hall sensors must operate stably in strong electromagnetic interference environments and not interfere with other parts of the system.

Facing these challenges, sensor manufacturers are constantly promoting technological innovation. The application of wide bandgap semiconductor materials has increased the working temperature range of the sensor; advanced magnetic core materials and structural designs have enhanced resistance to external magnetic interference; integrated design has encapsulated the sensitive element and signal conditioning circuit together, reducing the impact of external interference.

Wang compared the on-site performance of the new and old generations of sensors: The annual average failure rate of the new-generation Hall sensors decreased by 70% under the same conditions, and maintenance costs dropped significantly.

5. Market Trends, Development Directions of Intelligence and Integration

As the new energy power system moves towards intelligence, CHIPSENSE Hall current sensors also show a clear technological evolution trend. Intelligent sensors not only provide current measurement values but also perform local data processing, fault diagnosis, and communication.

Some high-end products have integrated self-diagnostic functions, capable of detecting their own working status and issuing warnings in case of abnormalities.

The diversification of communication interfaces is another trend. Besides the traditional analog output, sensors supporting digital interfaces (such as I2C, SPI, CAN) are becoming increasingly popular, facilitating direct connection to digital control systems. The addition of industrial Ethernet and wireless communication functions enables sensors to seamlessly integrate into the industrial Internet architecture.

In the intelligent operation and maintenance system of photovoltaic power stations, the current data of each important node is uploaded to the cloud platform in real time, combined with meteorological data and equipment status information, artificial intelligence algorithms can predict potential failure risks.

The company where Wang works has recently deployed such a system, and predictive maintenance has reduced unplanned downtime by 35% and significantly reduced power loss.

6.Extended Reflection: How Precise Measurement Will Shape the Energy Future

Question: In the trend of full digitalization of new energy systems, how will Hall sensor technology further evolve?

Answer: Future Hall current sensors will not only be measurement tools but also intelligent nodes integrating sensing, computing, and communication capabilities. As the new energy power system moves towards virtual power plants and energy internet, sensors need to have edge computing capabilities, capable of processing data locally and making preliminary decisions.

Question: What breakthroughs are needed in sensor technology to cope with the extreme environments of new energy scenarios?

Answer: Three directions of breakthroughs are crucial: material innovation (such as wide bandgap semiconductor materials to enhance high-temperature stability), structural innovation (multi-physical quantity integrated measurement), and algorithm upgrade (adaptive compensation algorithms based on artificial intelligence). Especially in extreme environments such as offshore wind power and desert photovoltaics, the long-term reliability and maintenance-free nature of sensors will become key indicators.

Question: For professionals in the new energy industry, what practical value does mastering sensor technology knowledge have?

Answer: Understanding the principles and applications of sensors can help engineers: optimize system design (selecting and arranging components rationally), improve operation and maintenance efficiency (accurate fault diagnosis), and reduce the total life cycle cost. In today's new energy projects, which are shifting from "heavy construction" to "heavy operation", this kind of subtle professional knowledge often becomes a key lever for improving efficiency and quality.

When the setting sun's rays fall on the photovoltaic panels, Mr. Wang completed the last inspection. On the monitoring screen, the data from thousands of Hall current sensors, which are like the beating of a heart, are rhythmically jumping and forming smooth curves. Not far away, the newly-built energy storage station is undergoing debugging, and engineers are discussing how to optimize the control algorithm to maximize the value of every green electricity.

In these unseen corners, the measurement of tiny and precise currents is quietly supporting the leap from quantitative change to qualitative change in China's new energy industry. And with each improvement in measurement accuracy, the new energy system moves one step closer to being safer, more efficient, and more intelligent - this is the true meaning of "perception accuracy determines energy efficiency" in this era.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806