In recent years, the global energy storage market has shown explosive growth. According to relevant data, the new installed capacity of global energy storage in 2024 is about 175.4 GWh, and it is expected that the new capacity will reach 247 GWh in 2025, an increase of 35% year-on-year. However, with the expansion of energy storage scale, safety accidents have also increased year by year. Statistics show that from January to May 2025, there were 18 new energy storage-related safety accidents worldwide, of which system-level defects accounted for as high as 72%. As "invisible killers" of energy storage systems, insulation failures and leakage have become the core risks that threaten system safety. This article will focus on insulation faults in electrochemical energy storage systems and explore the application of leakage monitoring technology. CHIPSENSE leakage current sensors will play an important role in it.

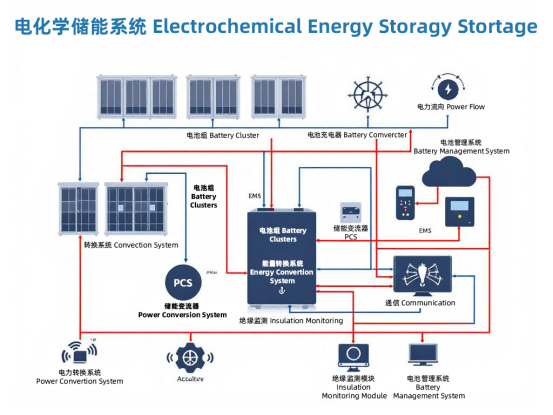

Power flow: Power transfer between battery pack, PCS, load/grid.

Communication data flow: Collaborative control between modules through data exchange.

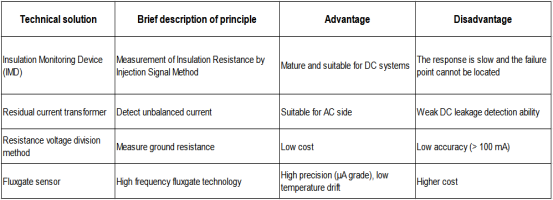

Comparison of technical solutions for energy storage leakage monitoring

In order to deal with the above risks, in addition to using redundant insulation and fault isolation measures in the design stage, insulation resistance testing and real-time leakage current monitoring need to be strengthened. The following is a comparison of common leakage monitoring technical solutions:

Conclusion: The fluxgate technology is more suitable for the strict monitoring of small leakage current in energy storage system because of its high precision and fast response characteristics. CHIPSENSE made a series of fluxgate current sensors for this needs.

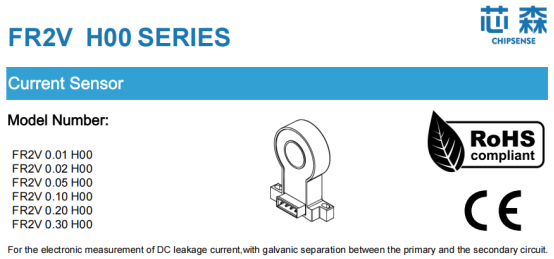

The fluxgate leakage current sensor adopts high-frequency fluxgate technology, which can realize micro-ampere leakage current monitoring and is suitable for DC side insulation fault detection of electrochemical energy storage systems. Its core advantages include:

Typical application scenarios

Battery stack insulation fault detection: prevent thermal runaway caused by DC side short circuit.

DC bus leakage monitoring: ensure the safe operation of the system.

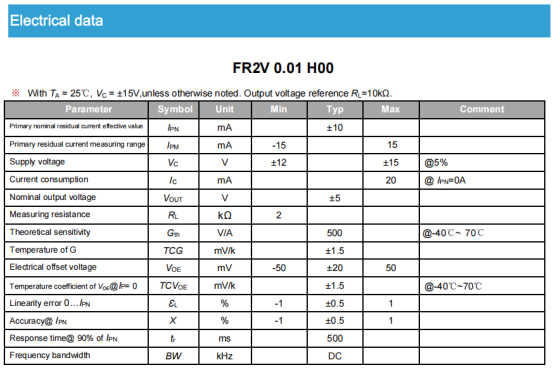

Example of technical parameters

Supply voltage: ± 12 V~ ± 15 V

Rated range: ± 10 mA to 300 mA

Measuring range: ± 15 mA~ 360 mA

Operating temperature: -40 ° C~ 70 ° C

Theoretical gain: 500 V/A

Linearity: 0.5%

Insulation faults and leakage are major hidden dangers for the safe operation of energy storage systems. By adopting high-precision monitoring technologies such as fluxgate leakage current sensors, real-time monitoring of tiny leakage currents can be realized, faults can be detected and dealt with in time, and thermal runaway and fire accidents can be effectively prevented. In the design and operation and maintenance of energy storage systems, redundant insulation design, environmental control and high-precision monitoring technologies should be combined to build a multi-level safety protection system.

CHIPSENSE fluxgate leakage current sensor provides customers with safety and convenience.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806