As renewable energy gradually replaces large-scale fossil fuel power generation, the volatility of renewable energy can easily impact the power grid. Therefore, Grid-Forming Storage technology has been introduced to stabilize the renewable energy grid.

On December 6th, the largest Grid-Forming Storage power station project in China, and arguably the largest in the world to date, officially commenced operation. This project utilizes grid-based technology, with a storage capacity of 1000 MW/4000 MWh (1 GW/4 GWh), directly connected to the 220 kV side of the 500 kV Arongqi substation. This project will significantly improve the local capacity to absorb wind and solar power, outputting 1.032 billion kWh of green electricity annually and reducing coal consumption by approximately 300 million tons. So, how is current monitoring performed in this new type of energy storage system with large capacity, high voltage, and rapid dynamic response? CHIPSENSE current sensor will also be involved.

What is "Grid-Forming Storage"?

Grid-forming storage is an advanced energy storage technology capable of autonomously constructing and maintaining stable grid voltage and frequency. It generates a constant AC voltage source by controlling a converter, thus achieving operating characteristics similar to a synchronous generator. Unlike grid-following storage, which relies on grid phase information, grid-forming storage does not require phase-locked loops (PLLs) for synchronization. It can operate independently in weak grid or off-grid environments, providing voltage and frequency support for the power system and actively supporting grid security. It is particularly suitable for power systems with a high proportion of renewable energy integration. The application areas of CHIPSENSE current sensor also include this.

Grid-forming storage is a necessity for building a new "high-efficiency, high-voltage, and high-value" power system and a key technology for solving the problems of renewable energy consumption and the safe and stable operation of the power grid. CHIPSENSE current sensor also knows.

Key Features

Voltage Source Characteristics: Essentially a voltage source, capable of independently setting and outputting stable voltage and frequency.

Active Support: Does not passively follow the grid, but actively provides inertia and voltage support, enhancing system strength.

Islanding Operation: Can operate independently of the main grid, providing power in microgrids or remote areas.

Virtual Synchronous Machine: Equivalent to a large synchronous generator, providing inertia and damping.

Working Principle

Virtual Synchronous Generator (VSG) Technology: Simulates the inertia and damping characteristics of a synchronous generator through control algorithms, enabling the energy storage system to operate stably like a traditional generator.

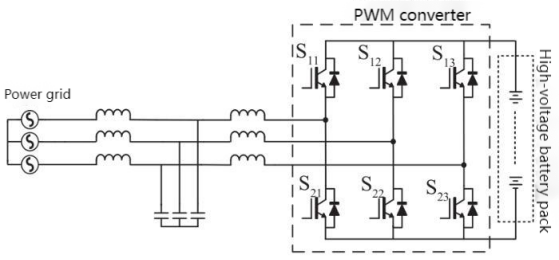

Energy Storage Converter (PCS): As the core hardware, it adjusts active and reactive power output in real time, responding to grid demands in milliseconds.

Single-stage energy storage PCS topology diagram

Grid-Connected (Grid-Standing): Relies on grid signals, passively adapting, like "limbs" performing power regulation.

Grid-Building: Actively "creates" the grid, like the "heart" maintaining vital signs and providing a stable foundation.

Current monitoring requirements for Grid-Forming Storage systems:

Grid-Forming Storage systems do not follow the power grid but rather define its rules, actively establishing support for grid voltage, frequency, and inertia, resulting in a response speed far exceeding that of ordinary inverters. Therefore, the requirements for current sensors are significantly higher. Therefore, CHIPSENSE current sensor was also developed accordingly.

High precision:

The system needs to monitor battery charging and discharging current in real time (for SOC estimation, over-current protection, etc.) and PCS output current (for power control, harmonic analysis). Measurement accuracy directly affects system decision-making and grid quality. For example, the typical accuracy of current monitoring in a battery management system (BMS) needs to reach ±1% @25℃, while fluxgate technology can even achieve an extremely high accuracy of 0.01%. CHIPSENSE current sensor can also achieve very high performance.

High-frequency bandwidth & fast dynamic response:

Grid-Forming Storage needs to cope with instantaneous fluctuations in the power grid. Current sensors need to have fast response capabilities (such as tracking time ≤ 5μs) and wide dynamic range to accurately capture current changes from tens of mA to thousands of A, meeting the needs of all scenarios from module-level monitoring to system output. The applications of CHIPSENSE current sensors are also very wide, and they can even be customized.

Stability in Extreme Environments:

The sensor must maintain stable output under complex operating conditions such as wide temperature ranges (e.g., -40℃ to 150℃), strong electromagnetic interference (e.g., 10kV/m), and high humidity/dust (IP67 protection rating) to ensure data reliability. CHIPSENSE current sensors have been supplied to customers in remote areas and have received positive feedback from them.

High Isolation and Safety:

High-voltage DC systems require the sensor to have high isolation withstand voltage (e.g., 4.8kV) to ensure personnel safety and equipment insulation. The CHIPSENSE current sensor has no safety issues in customer use. Simultaneously, a zero insertion loss design avoids impacting system efficiency.

Wide Measuring Range and Overload Capacity:

Measuring Range: The range must cover a wide spectrum from no-load to twice the rated current to handle high-current conditions during fault ride-through or transient overload in grid-connected energy storage (e.g., 1.5 times overload for 10 seconds).

Overload Tolerance: The sensor must have short-term overload capability (e.g., 3 times the rated current for 1 second) to prevent damage during grid faults.

Multi-dimensional Monitoring Requirements

Three-phase imbalance monitoring: Grid-Forming Storage needs to independently support three-phase voltage, therefore, it is necessary to monitor the amplitude and phase difference of the three-phase current in real time to ensure the symmetry of the output voltage.

Harmonics and DC components: It is necessary to monitor the harmonic content (e.g., THD < 3%) and DC component in the current to prevent harmonics from being injected into the grid or affecting the safety of the converter.

Wide-band monitoring: It is necessary to cover a wide bandwidth of 0.1Hz to 1kHz to identify sub-synchronous oscillations or high-frequency noise in the grid.

Reliability and Redundancy Design

Redundancy Configuration: Critical nodes (such as the grid connection point PCC) require dual or triple redundant current sensors to ensure stable system operation even in the event of a single sensor failure.

Interference Immunity: Sensors must possess high common-mode rejection ratio (CMRR > 120dB) and electromagnetic compatibility (EMC) design to resist converter switching noise and grid harmonic interference.

Self-Diagnostic Function: A real-time self-test mechanism must be integrated, such as sensor disconnection, saturation, or drift detection, to trigger protection actions.

Coordination with the Control System

Closed-Loop Control: Current monitoring data needs to be directly connected to the grid controller as feedback signals for the Virtual Synchronous Machine (VSG) or droop control, achieving millisecond-level response. CHIPSENSE current sensors are all fast-responding.

Fault Ride-Through: In the event of grid short circuits or other faults, rapid monitoring of fault current is required, supporting low-voltage ride-through (LVRT) or high-voltage ride-through (HVRT) strategies.

Black Start Support: In off-grid or black-start scenarios, monitoring of current changes within the microgrid is necessary to ensure the system can autonomously establish voltage and frequency.

Technology selection recommendations:

| Sensor Types | Advantages | Disadvantages | Applicable Scenarios |

| Hall Current Sensor | Wide bandwidth, high precision, isolated measurement; | Susceptible to temperature drift, higher cost; | High-precision monitoring, wide-range applications; |

| Fluorescence Gate Sensor | extremely high precision, low drift; | smaller measuring range, slower response time; | Precision monitoring of DC component or small current; |

| Rogowski Coil | no saturation, wide bandwidth, high overload capacity; | requires integrating circuit, susceptible to interference; | Transient current, fault recording; |

| Shunter | low cost, high precision. | no isolation, high power consumption. | Small-capacity systems or auxiliary monitoring. |

The control requirements for Grid-Forming Storage are extremely stringent:

High-frequency PWM: 16–48kHz

Extremely rapid current surges

Sub-millisecond response required for fault ride-through

Therefore, sensors need:

Bandwidth ≥100kHz (200kHz+ recommended)

Response time < 1–2μs. Traditional shunts, low-bandwidth Hall effect sensors, and current transformers (CTs) struggle to meet these requirements.

High-performance Hall effect ASICs and closed-loop Hall effect sensors have become the mainstream choices. CHIPSENSE current sensor is a good choice.

Typical Applications of Hall Current Sensors in Grid-Forming Storage

The applications of Hall current sensors in Grid-Forming Storage systems cover a wide range of aspects, mainly including current monitoring, protection, control, and fault diagnosis.

1. PCS Main Current Detection (High Bandwidth + High Current)

For example, the AC/DC side of the energy storage converter (PCS) needs to monitor a high current (e.g., ±5000A) in real time to ensure stable system operation. It can choose the high current of the CHIPSENSE current sensor.

Hall Sensor Selection

Closed-Loop Hall Sensor:

Measuring Range: 100A~2000A (or higher, such as CHIPSENSE CM9A 5000A current sensor).

Accuracy: 0.3%~1% (meets the high accuracy requirements of grid-type energy storage).

Bandwidth: 100kHz (captures high-frequency transient currents).

Response Time: <1μs (meets millisecond-level control requirements).

Technical Advantages:

High Isolation: Primary and secondary insulation withstand voltage ≥6kV, ensuring safety.

Wide Measuring Range: Covers overload conditions (e.g., 1.5 times rated current).

Low Temperature Drift: Adapts to temperature variations in outdoor energy storage (-40°C~85°C). The temperature range of the CHIPSENSE current sensor is also quite wide.

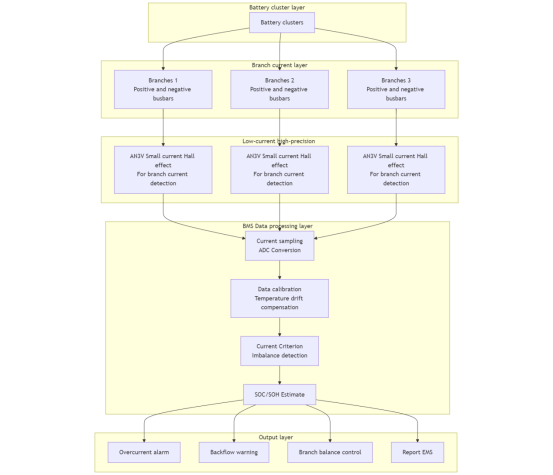

2.Battery Cluster/Branch Current Detection (High Precision + Low Current)

In grid-type energy storage systems, the charge and discharge current of each battery cluster needs to be monitored to achieve SOC (State of Charge) estimation and equalization control.

Hall Sensor Selection

Closed-loop Hall sensor (e.g., CHIPSENSE CR1A/CS1V series current sensor):

Range: 50A~300A (suitable for battery cluster-level monitoring).

Accuracy: 0.5%~1%.

Response time: <3μs.

Technical Advantages

High Precision: Ensures accurate SOC estimation.

Low Power Consumption: Reduces impact on the Battery Management System (BMS).

Redundant Design: Multiple sensors connected in parallel improve reliability.

3. DC/DC Loop Current Detection (Bidirectional High Frequency)

Current sensor applicable to bidirectional power flow scenarios such as photovoltaic-energy storage, wind-energy storage, and converter units:

Requires high bandwidth

Consistent bidirectional accuracy

Unaffected by di/dt interference

4. Virtual Synchronous Machine (VSG) Control

Grid-Forming Storage simulates the inertia and frequency regulation characteristics of a synchronous generator using Virtual Synchronous Machine (VSG) technology. Hall effect sensors are used to monitor:

Active/Reactive Current:** Achieving droop control and frequency support.

Transient Current:** Responding to grid frequency fluctuations.

Hall Sensor Selection

High-Precision Closed-Loop Hall Sensors (e.g., CHIPSENSE CM9A series current sensor):

Accuracy: 0.1%~0.5%.

Bandwidth: 10kHz~100kHz.

Technical Advantages

High Precision: Ensures the accuracy of VSG control.

Low Latency: Real-time response to grid frequency changes.

Interference Resistance: Suppresses converter switching noise.

Limitations and solutions of Hall effect sensors in Grid-Forming Storage

| Limitations | Solutions |

| High-frequency noise interference | Use differential design or digital filtering to suppress noise |

| temperature drift | Select a low-temperature drift sensor or add a temperature compensation algorithm |

| range limitation | Use multiple sensors in parallel or segmented range designs |

| high cost | Use open-loop Hall sensors (such as CHIPSENSE AN3V current sensor) in non-critical loops to reduce costs |

Conclusion

with the commissioning of the 1GW/4GWh Grid-Forming Storage project in Arongqi, China's energy storage industry is evolving from an "energy warehouse" to a "grid stabilizer." In this technological revolution, the value of current sensors is gradually being amplified. In the future, with the full-scale deployment of Grid-Forming Storage, Hall current sensors, possessing high bandwidth, high isolation, high precision, and high reliability, will become indispensable core components. CHIPSENSE will strive to develop its own current/voltage sensors and become the customer's first choice.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806