Recently, the billion-dollar collaboration between AMD and Open AI has attracted widespread attention in the industry, signaling that the AI computing power race has entered a new stage. While the industry's focus is on the grand narratives of cloud-based models, a key question emerges: how can these powerful AI systems truly be implemented to solve concrete industrial problems, such as electric vehicle charging safety? The answer may not lie in the algorithms themselves, but in the starting point of their decisions—data. And high-quality data comes from the front-end, often unnoticed, sensors. CHIPSENSE current sensor is a part of them.

Under the feast of computing power, the 'data cornerstone' for AI implementation is even more crucial.

The collaboration between AMD and Open AI aims to challenge NVIDIA's dominance and provide a more powerful computing foundation for global AI development. This is undoubtedly an important force driving technological progress. However, historical experience shows that no matter how sophisticated the top-level algorithms are or how powerful the computing power is, the effectiveness of their application ultimately depends on the quality of the input data. In the industrial sector, especially in the charging pile industry where life and property safety are at stake, unreliable data can lead AI models to make wrong judgments, with potentially disastrous consequences. Therefore, the first lesson in building an intelligent safety monitoring system is to solidify the foundation of data.The current sensors are an important component among them, and CHIPSENSE current senors will play an important role in it.

Core requirements for electric vehicle charging pile leakage monitoring

1.Specificity of Electric Leakage Risk-

In DC charging systems, leakage currents are usually at the milliampere level and are influenced by insulation aging and environmental factors, making them covert.

Traditional RCDs are mainly designed for AC leakage detection and have insufficient sensitivity to DC leakage, which can easily lead to missed or false alarms.

2.Monitoring Challenges

High accuracy requirements: It is necessary to detect very small currents at the ±10mA level, and the error must be controlled within ±0.5%. CHIPSENSE current sensors can do it.

Many environmental interferences: Electromagnetic interference, temperature changes, etc., can affect the stability of the sensor.

Short response time: Leakage faults need to trigger the protection mechanism within milliseconds to prevent the expansion of accidents.

3.Standards and Specifications

According to IEC 61800-5-1 and IEC 62109-1 standards, the leakage protection device of the charging pile must meet high precision and high reliability requirements, and pass strict insulation withstand voltage tests (such as 3kV/1min). CHIPSENSE all current sensors are manufactured to these high standards.

Key Technology Selection: Why Is Fluxgate Technology the Preferred Solution?

Among the various current sensing technologies, fluxgate technology achieves high-precision current measurement through the magnetic saturation effect, and is especially suitable for detecting very small DC currents. It is considered the preferred solution for high-precision DC leakage monitoring. Currently, there are many domestically produced fluxgate current sensors with high precision, wide range and frequency response, high stability, and low temperature drift, which are 100% domestically made and compatible with mainstream international sensor models. For example, taking the CHIPSENSE FR2V series current sensors, CHIPSENSE FR2V series current sensors includes the models: FR2V 0.01 H00, FR2V 0.02 H00, FR2V 0.05 H00, FR2V 0.10 H00, FR2V 0.20 H00, and FR2V 0.30 H00, with residual current measurement ranges from 0.01 to 0.3 A. AI Sensors: Technological Upgrades and Safety Challenges in Charging Pile Leakage Monitoring

The compatibility of CHIPSENSE FR2V H00 current sensor is as follows:

1.Ultra-high precision: Fluxgate technology can stably detect micro DC currents at the milliampere level. This ability to capture "the slightest traces" provides the data foundation for AI early warning systems. CHIPSENSE has also developed this type of fluxgate current sensor.

2.Extremely low zero-point temperature drift: The technology itself ensures that its zero-point error is minimally affected by temperature changes. This means that whether at the peak of summer or in the depths of winter, the sensor can provide accurate and reliable readings, avoiding false alarms caused by self-drift, and offering high-quality data input for AI models. So CHIPSENSE current sensors has received high praise from many customers for its precision.

3.Inherent isolation safety: Current sensors using fluxgate technology naturally have high insulation strength between the primary side (high-voltage measured side) and the secondary side (signal output side). This easily meets international safety standards, such as IEC61800-5-1, for reinforced insulation, CHIPSENSE current sensors ensuring the safety of the entire system.

Taking CHIPSENSE FR2V 0.01 H00 current sensors as an example, its key parameters are as follows:

| Parameters | Type Value | Comment |

| Primary rated residual current | ±10mA | Suitable for micro-leakage detection |

| Accuracy | ±0.5% | Higher than industry standards |

| Response time | 500ms | Meets rapid protection requirements |

| Insulation withstand voltage | 3kV(50Hz/1min) | Complies with IEC 62109-1 CAT III |

| Creepage distance | 7.2mm | Ensures safe insulation |

In comparison, traditional Hall sensors often have limitations in terms of accuracy and temperature drift. In scenarios like charging station safety, where reliability is critical, CHIPSENSE FR2V current sensors provide a reliable technical solution for leakage monitoring in charging stations, thanks to their high accuracy, low temperature drift, and strong insulation characteristics. Real-time data collection and rapid response mechanisms represent a rational first step towards AI integration. And CHIPSENSE current sensor is a good choice for customers.

Pathways of AI Safety Monitoring: From 'Threshold Alarms' to 'Trend Prediction'

The introduction of AI aims to achieve a paradigm shift in safety monitoring.

Pattern Recognition: AI models can identify subtle abnormal patterns caused by early aging or moisture in insulating materials by analyzing complex features such as current wave-forms and harmonic components, thus issuing warnings before the current reaches dangerous thresholds.

Predictive Maintenance: Based on long-term, continuous high-precision data, AI can analyze the degradation trends of equipment performance, enabling predictive maintenance and fundamentally changing the passive approach of "repair after failure."

However, the premise for all these intelligent applications is that the current data provided by sensors must be sufficiently accurate, stable, and low-noise. If the sensors themselves have significant zero-point temperature drift or insufficient accuracy, the AI model will learn a biased "world model," and the predictions and warnings it produces will naturally lose credibility.

Building a Closed Loop: From 'Precise Perception' to 'Intelligent Decision-Making'

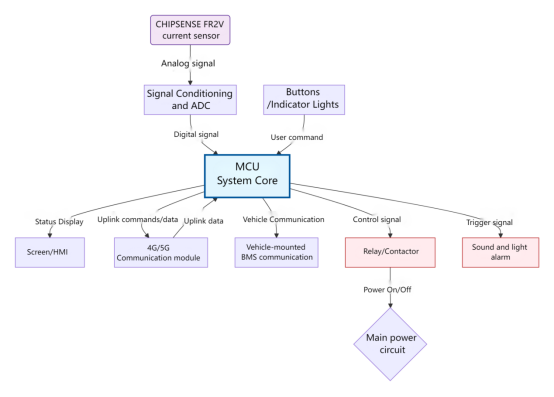

When high-precision sensors are in place, a complete AI security monitoring closed loop can be established:

Perception Layer: High-precision current sensors act as 'nerve endings,' collecting the most original and authentic current data 24×7 hours.

Edge Computing Layer: Local processors equipped with AI acceleration chips analyze the data in real time, performing preliminary fault diagnosis and rapid response.

Cloud Platform: Massive amounts of data converge in the cloud, where deep mining, pattern optimization, and algorithm iteration are conducted using large models provided by platforms such as Open AI, and the more intelligent models are then deployed back to the edge.

Conclusion

The collaboration between AMD and Open AI outlines a grand blueprint for the development of AI computing power. However, turning this blueprint into concrete practices for charging station safety begins with choosing highly reliable sensing technologies capable of capturing real and subtle fault signals. The intelligent upgrade of the industry is a 'duet' between underlying hardware (sensors) and top-level algorithms (AI). Only through their synchronized evolution can the industry achieve the leap from 'passive protection' to 'active immunity,' thereby building a solid safety foundation for the vigorous development of the electric vehicle industry. CHIPSENSE will also continuously upgrade and optimize its current sensors according to the marking needs.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806