Foreword: While everyone's attention is focused on the glittering $4,000 gold price, smart capital has already begun new arrangements. This global surge in risk aversion and investment is quietly driving a more promising sector—the comprehensive upgrade of new energy infrastructure. In the 'heart' of photovoltaic power plants—the inverters, with high-precision current monitoring technology has become the key to improving power generation efficiency and ensuring investment returns.

On October 8th, during China's National Day holiday, the international spot gold price surpassed the $4,000 per ounce mark for the first time. This was primarily driven by recent events such as the U.S. government shutdown and escalating conflicts in the Middle East, which heightened global risk aversion. Coupled with declining confidence in the U.S. dollar, rising expectations of a Federal Reserve interest rate cut, and accelerated global de-dollarization, central banks in multiple countries have increased their gold holdings for 11 consecutive months since November last year. Gold, as a safe-haven and hedging asset, has become highly favored. At the same time, after gold prices broke through $3,500 per ounce, technical indicators strengthened, and market bullish sentiment grew. With multiple positive factors converging, the gold bull market has entered an accelerated phase.

Against the backdrop of global de-dollarization and increasing geopolitical risks, sectors such as infrastructure, technology, and green energy in emerging markets are attracting capital inflows due to their growth potential and policy support. New energy, particularly photovoltaic power generation, with its clear industrial policies and huge market potential, may have become the key investment focus of this wave of capital frenzy.

After entering 2025, investment in photovoltaic power plants has clearly shifted from the extensive model of 'acquiring land and building plants' to a more refined pursuit of 'power generation efficiency' and 'operational returns.' In terms of improving power generation efficiency, core equipment such as photovoltaic modules, inverters, and tracking systems are continuously being upgraded. Technologies like N-type high-efficiency batteries, bifacial modules, and intelligent tracking mounts are widely applied, significantly increasing power generation per unit area. For example, N-type module conversion efficiency has exceeded 25%, bifacial modules can increase power generation by 5%-20%, and intelligent tracking systems can enhance generation efficiency by 3%-10%.

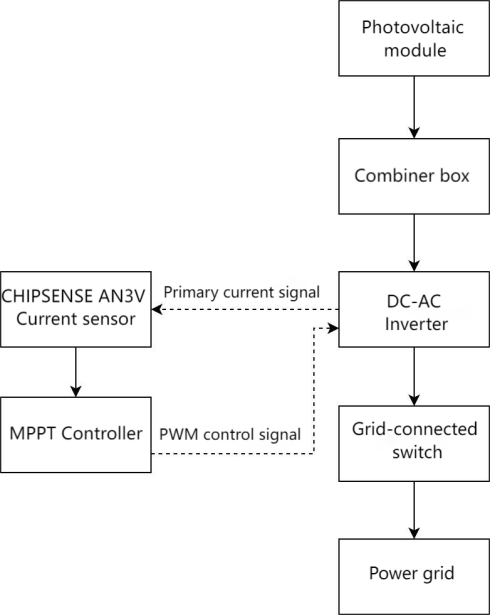

Inverter as the core equipment of a photovoltaic power generation system, the performance of the inverter directly affects the overall system's power generation efficiency. CHIPSENSE current sensor also play an important role in it. Inverters use current sensors to accurately measure and feedback current data, which directly and indirectly enhances the efficiency of the photovoltaic system. Its main functions and mechanisms are as follows:

1.Precise MPPT (Maximum Power Point Tracking) implementation

Real-time Current Monitoring: The current sensor collects the output current of the photovoltaic modules in real time. Combined with voltage data, it helps the MPPT algorithm accurately lock onto the maximum power point. Especially when there are rapid changes in sunlight (such as cloud cover) or inconsistent aging of the modules, high-precision current measurement can prevent MPPT algorithm misjudgments, ensuring the system always operates at the optimal point and reducing power generation losses (which can improve generation efficiency by 1%-3%).

Dynamic Response: High-bandwidth, low-latency current sensors (such as Hall effect sensors) can quickly respond to changes in sunlight, allowing the MPPT algorithm to adjust more promptly and avoid energy waste.

2.Improve inverter conversion efficiency

Closed-loop control: The inverter uses data feedback from the current sensor to adjust the PWM (Pulse Width Modulation) signal in real time, optimizing the switching timing of IGBTs or MOSFETs, reducing switching losses and harmonic distortion, and improving inverter efficiency (especially noticeable under partial load conditions).

Harmonic suppression: By accurately measuring the harmonic components in the output current,the inverter can dynamically adjust the filtering parameters, reduce harmonic losses, improve grid-connected power quality, and indirectly enhance system efficiency.

3.Support grid connection and grid compatibility

Grid Synchronization: In grid-connected inverters, current sensors monitor the phase and amplitude of the grid current to ensure that the inverter output is synchronized with the grid, reducing reactive power and harmonic injection, and improving grid connection efficiency.

Low Voltage Ride Through (LVRT): During grid faults, current sensors help the inverter quickly detect and respond to the grid status, adjust the output according to standard requirements, prevent disconnection from the grid, and reduce power generation interruptions.

4.Optimization of Energy Storage System Coordination

Charge and discharge management: In an photovoltaic energy storage system, current sensors accurately measure the charge and discharge currents of the energy storage batteries, optimize charging strategies (such as maximum charge efficiency point tracking), reduce energy conversion losses, and improve the overall efficiency of the energy storage system.

Energy balance: In hybrid systems (such as photovoltaic, energy storage, and diesel generators), current data helps inverters balance multiple energy inputs, maximize self-consumption ratios, and reduce photovoltaic curtailment losses.

5.Improve low-light power generation performance

Weak current detection: High-sensitivity current sensors (such as zero-fluxgate sensors) can accurately measure tiny currents under low-light conditions (such as early morning or cloudy days), ensuring that the inverter operates efficiently even with low power input and extending daily power generation time.

6.Data-Driven Intelligent Operations and Maintenance

Remote monitoring: Current data is uploaded to the cloud platform, where big data analysis identifies system bottlenecks (such as mismatched components or line losses) and guides operation and maintenance optimization.

Predictive maintenance: By combining AI algorithms, current waveforms and trends are analyzed to predict equipment failures (such as capacitor aging or IGBT performance degradation), allowing for proactive intervention to prevent efficiency loss.

Application framework diagram of CHIPSENSE AN3V current sensor in photovoltaic inverters

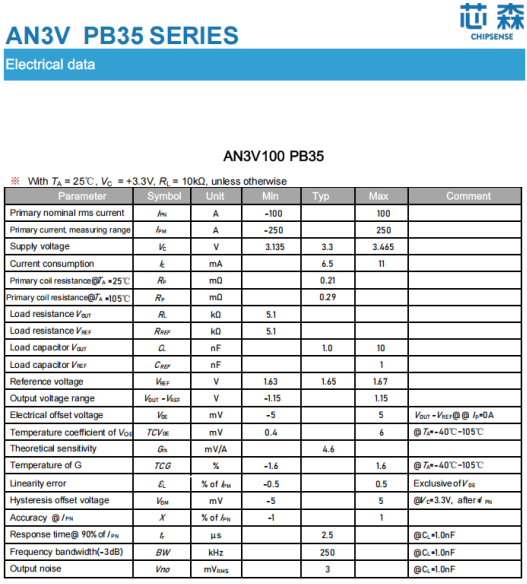

Modern inverters integrate current sensors with control circuits, reducing signal interference and transmission loss, thereby further improving system reliability. For example, the AN3V PB35 series Hall open-loop current sensors independently developed by CHIPSENSE play a key role in photovoltaic inverters, with core advantages including:

CHIPSENSE current sensor ±1% high precision with a gain error temperature drift of only ±1.6%, ensuring the MPPT algorithm obtains accurate current data, precisely locks the maximum power point of the PV array, and reduces power generation losses (can improve power generation efficiency by 1%-3%).

The primary-side current bus uses tin-plated copper with very low resistance. The product size is only 22.2*13.3*12.4mm, making it easy to integrate and solder onto PCBs, supporting modular design;

CHIPSENSE current sensor covers a rated measurement range from 80A to 200A, meeting the needs of inverters with different power levels;

The response time is only 2.5μs, with an output bandwidth of up to 250 Hz, quickly capturing changes in light or load fluctuations. This allows the inverter to dynamically adjust the PWM duty cycle, reducing energy waste. These two features make it better suited for high-frequency inverters, supporting high-frequency switching of wide-bandgap devices such as SiC/GaN, reducing switching losses and improving overall efficiency.

Power supply voltage is only 5V/3.3V, with no insertion loss, reducing overall system loss;• Operating temperature -40~105°C, suitable for different working environments, ensuring stability under high and low temperatures and humidity.

Primary and secondary insulation withstand voltage of 4.3kV (AC) and 8kV (transient), creepage distance >8mm, compliant with IEC62109-1 CATIII standard, suitable for 600V/1000V photovoltaic systems, no additional insulation measures required, simplifying inverter structure.

Low temperature drift design: zero output voltage temperature drift is only ±6mV (full temperature range), gain drift ±1.6%, reducing MPPT deviation caused by temperature changes;

Micro-Current Detection: High-gain design (e.g., CHIPSENSE AN3V 80 PB35 current sensor with a gain of 5.75 mV/A) can accurately measure tiny currents under low light conditions (such as early morning or late evening), ensuring the inverter operates efficiently even at low power input, thereby extending daily power generation time;

Analog Output Voltage (Vout-Vref) directly reflects the primary-side current, facilitating MCU data acquisition and analysis, and enabling: detection of module aging, hot spots, or shading faults; assisting the system in uploading current data to the cloud platform to optimize operation and maintenance strategies; real-time monitoring of abnormal currents, triggering protection mechanisms to prevent device damage.

Standards Compliance of CHIPSENSE current sensor: EC60664-1:2020, IEC61800-5-1:2022, IEC62109-1:2010 (photovoltaic inverter safety standards)

The AN3V PB35 series current sensor from CHIPSENSE, featuring high precision, fast response, strong insulation, wide temperature adaptability, and low power consumption, has become a key component for improving the efficiency of photovoltaic inverters, particularly excelling in MPPT optimization, dynamic efficiency enhancement, and intelligent operation and maintenance. CHIPSENSE current sensor is a good choice among peers.

Conclusion:

The surge in gold prices may be superficial, while the energy revolution is the core. The direction of capital often reveals the main trajectory of future economic development. For the photovoltaic industry, future competition will also depend on the competition in technical details. Core components such as current sensors like CHIPSENSE AN3V series current sensors are key to enhancing the value of power station assets and ensuring returns on capital investment. With the development of technologies such as AI smart operation and maintenance and virtual power plants, the requirements for front-end data collection will become increasingly demanding, and the foundational role of current sensors will become even more prominent. We believed that CHIPSENSE current sensor will also become the customer's first choice.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806