"Has it snowed where you are?" Even before the start of winter, many parts of the country have recently experienced a strong cold wave, with a sharp drop in temperature causing a rapid increase in electricity demand. From residential heating to urban transportation, and to critical facilities such as hospitals and data centers, stable power supply has once again become a focus of public attention.

Among various emergency power supply solutions, UPS (Uninterruptible Power Supply) systems are the invisible line of defense—they can instantly switch to battery power when the mains power fluctuates or is interrupted, ensuring uninterrupted power to core equipment.

However, to achieve "seamless switching" in a UPS system, one crucial aspect is often overlooked—the accuracy and response speed of current detection. CHIPSENSE current sensors are use for it.

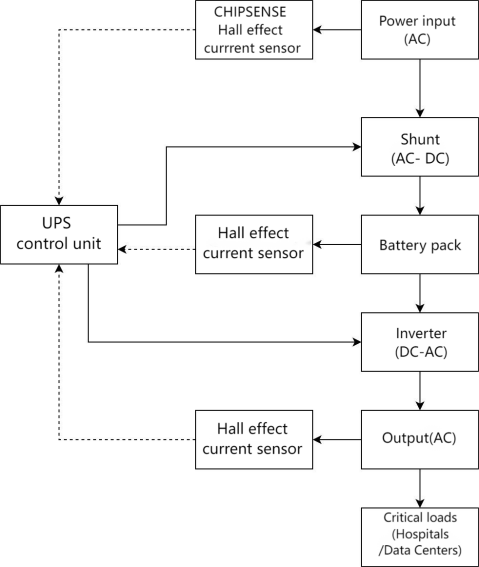

UPS systems have multiple current paths: rectification, inversion, battery charging/discharging, bypass switching, etc.

In scenarios with low temperatures or sudden changes in large loads, these currents often change on a millisecond scale.

Engineers are most concerned about control distortion caused by detection lag, for example:

Switching delays cause output voltage flickering;

Over-discharge or over-current charging of batteries is misjudged;

Some modules overheat but are not detected in time.

While traditional shunt resistor sampling methods are simple, they suffer from several long-standing problems—high power loss, difficulty in isolation, and high levels of signal noise, especially noticeable in high-power UPS systems.

This is why many new UPS systems emphasize current sensing from the design stage.

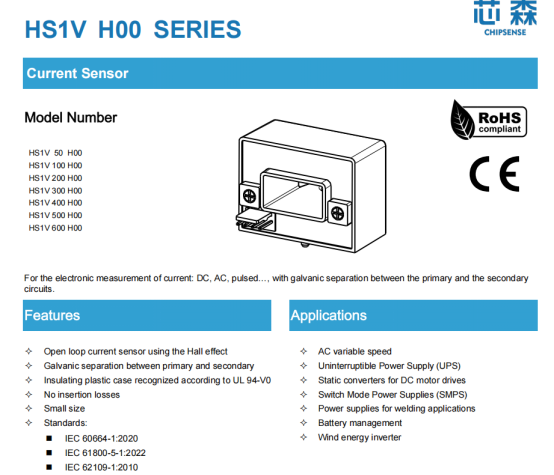

In recent years, Hall effect-based current sensing schemes have been increasingly incorporated into UPS designs. CHIPSENSE hall effect current sensor is one of them.

This scheme does not require direct contact with the circuit; instead, it achieves isolated measurement by inducing changes in the primary current through a magnetic field. Its advantages include:

Fast Response: Millisecond-level response time (CHIPSENSE HS1V series current sensors have a response time as low as 3μs), enabling real-time capture of current surges and helping UPS systems complete power switching within 5ms, significantly reducing the risk of power outages;

Low Loss: Non-contact measurement method, no need to disconnect the main circuit, simplifying system integration and reducing maintenance costs;

Safety isolation: Meets the insulation requirements of high-voltage systems;

Wide measuring range: Covers testing needs from a few amperes to thousands of amperes.

In large data center and rail transit UPS systems, this type of solution has gradually replaced traditional sampling resistors.

Engineers can directly place sensors on the DC bus or inverter branches to monitor the charging and discharging status in real time, enabling smoother control strategies. Meanwhile, CHIPSENSE current sensors have solved this problem for many customers.

Previously, current sensing was only used for protection. But now it is becoming one of the important inputs for intelligent control of UPS systems. Through more accurate current sensing, control algorithms can:

Predict load trends in advance when mains power fluctuates;

Optimize battery discharge curves and extend battery life;

Improve overall system energy efficiency and reduce unnecessary losses.

It can be said that current sensing is no longer just a measuring tool, but rather the "nerve endings" of a UPS system. The resilience of future energy depends not only on the strength of the power supply, but also on the accuracy of the sensing. CHIPSENSE has always focused on high-precision, high-quality current sensors.

1. Real-time Current Monitoring: Integrating CHIPSENSE HS1V current sensors at the UPS input and output terminals monitors load current and battery charge/discharge status in real time, providing millisecond-level feedback data to the controller for optimized switching logic.

2. Overload Protection: CHIPSENSE current sensor through precise current measurement, transient overloads are promptly identified, triggering protection mechanisms to prevent battery over-discharge or inverter damage.

3.Battery Health Management: Combining current data analysis with battery charge/discharge curve prediction helps predict battery life, enabling proactive maintenance and extending battery lifespan. CHIPSENSE current sensors has been focusing on this issue.

4.System Integration Optimization: CHIPSENSE HS1V series current sensors supports ±15V power supply and outputs analog voltage signals (±4V@rated current), which can be directly connected to the UPS controller, simplifying the design.

Real-world application case: During a cold wave, a data center reduced the power switching time from 10ms to 5ms, extended battery life by 15%, and reduced annual maintenance costs by 20% by upgrading the current sensor in its UPS system.

Risk Warning and Recommendations.

Selection Considerations: Select a sensor with an appropriate range based on the UPS power rating (e.g., CHIPSENSE HS1V 200 H00 current sensor is suitable for systems up to 200A), and ensure the insulation class matches the application scenario.

Installation Specifications: Sensor installation must comply with IEC61800-5-1 standards, ensuring the primary busbar temperature does not exceed 105°C to avoid performance degradation. CHIPSENSE current sensors must meet these requirements.

Regular Calibration: CHIPSENSE current sensors will regularly check the sensor's electrical offset voltage (typical ±20mV) and gain error to ensure long-term stability.

Conclusion

When external temperatures plummet and power grid fluctuations become frequent, the resilience of a system is truly tested from within.

A stable and responsive current sensor often determines whether a UPS can stabilize the situation in critical moments. CHIPSENSE current sensors have invested a lot of effort in this area.

For engineers working on UPS, power supply, and energy storage projects, it may be worth re-examining: Have the accuracy, delay, and isolation methods of current sensing kept pace with the advancements in system intelligence? CHIPSENSE current sensors are also constantly upgrading their products.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806