By the first half of 2025, China's cumulative photovoltaic installed capacity had surpassed 1,000 gigawatts, marking the nation's entry into the terawatt era. Although new installations saw year-on-year growth, the pace of expansion slowed after June. Industry experts predict the market may transition from explosive growth to stable development, with the sector's focus shifting from ‘rush installations’ to ‘precise management’–that is, maximising every kilowatt-hour through meticulous operation and maintenance. This is precisely why CHIPSENSE current sensor adopts a customer-centric approach.

At SNEC 2025, multiple inverter and monitoring manufacturers coincidentally emphasised one direction: string-level current monitoring.

Why? Because actual measurement data reveals that local shading, module degradation or loose wiring alone can cause power generation losses of 15% to 30% in a single string. Without independent monitoring, such issues are often masked by ‘average values’, leading to prolonged operation with faults.

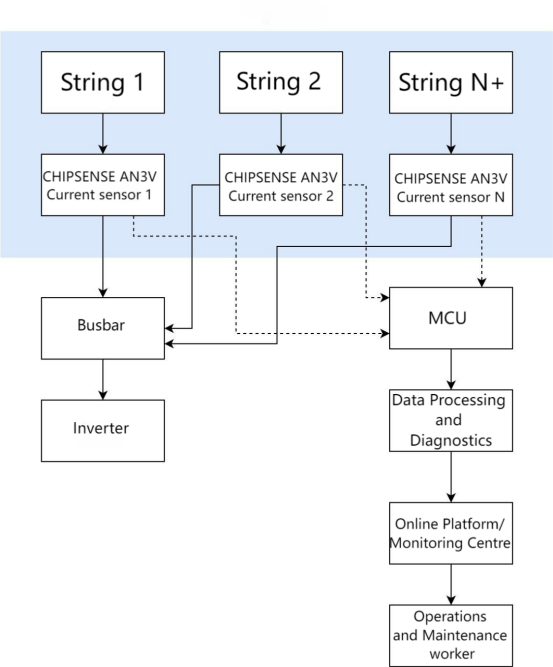

In string-based photovoltaic systems, the PV string combiner box connects the outputs of multiple PV strings in parallel before feeding them into the inverter. Its core functions include:

Combining: Aggregates the currents from multiple strings for consolidated output.

Monitoring: Continuously tracks parameters such as voltage and current for each string.

Protection: Provides safeguards including lightning protection, overcurrent protection, and insulation monitoring.

Communication: Transmits monitoring data to supervisory systems or cloud platforms.

In terms of monitoring, the precise and real-time monitoring of each string's current serves as an effective means for operations and maintenance personnel to swiftly identify anomalies such as string shading, hot spots, performance degradation, or wiring faults. CHIPSENSE current sensor also involve in it.

Here, cost-effective and highly reliable domestic current sensors may be employed. Within a 16- or 24-channel combiner box, a current sensor is connected in series with the positive output copper foil of each string. The output signals (VOUT) from all sensors are fed into a multi-channel ADC, where the MCU acquires real-time current data from each channel, enabling independent and synchronous monitoring of every string's current. The MCU continuously compares the current values across all strings. For instance, under identical illumination conditions, should a particular string's current (e.g., I₃) fall significantly below others, the system immediately identifies potential shading, hotspots, or wiring faults within that string. Historical data can also be analysed to flag strings exhibiting accelerated performance degradation, enabling proactive maintenance alerts. Upper and lower current limits may be set, triggering immediate alarms should sensors detect a string exceeding these parameters. Upon receiving this information, the operations platform forwards it to maintenance personnel. This process narrows fault localisation from ‘the entire power station ’to ‘a specific string’, significantly enhancing operational efficiency.

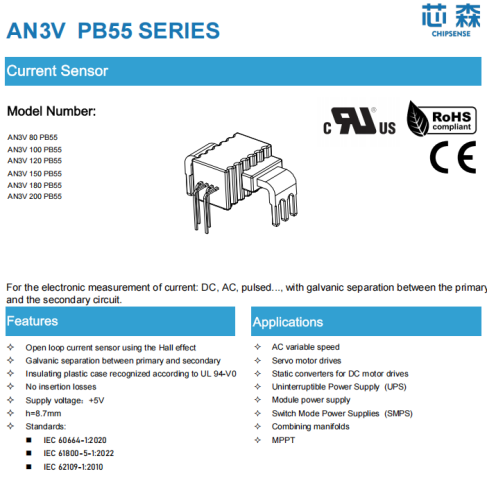

Take the AN3V series open-loop Hall current sensor from CHIPSENSE as an example.This current sensor is manufactured using automated production equipment independently developed by CHIPSENSE, ensuring high reliability and consistency.

Applicable models: CHIPSENSE current sensor AN3V 80 PB55 to AN3V 200 PB55 Covering mainstream string current scenarios

Core Capability:

CHIPSENSE current sensor with ±1% high precision and ±0.5% low non-linearity error, it can clearly distinguish minute current variations caused by shading, dust, or attenuation. For instance, where a normal string current is 10A, an abnormal string might be 8A or lower. A current sensor with ±1% accuracy can capture such changes.

Measurement range spans ±200A to ±375A, accommodating current fluctuations under varying light conditions and temperatures.

Powered by +5V supply with low power consumption (typically 6.5mA). The primary-side direct-through copper busbar (tin-plated copper material) exhibits extremely low resistance (0.21 mΩ), resulting in negligible insertion loss. Measurement does not diminish string output efficiency.

4.3kV AC isolation withstand voltage for 1 minute, with electrical clearance and creepage distance both exceeding 8mm. Complies with IEC 61800-5-1 and IEC 62109-1 standards (photovoltaic inverter safety standards), providing reliable reinforced insulation protection for the system. This constitutes a prerequisite for its application within combiner boxes.

Operates across a wide temperature range of -40°C to 105°C, withstanding extreme cold and high cabinet temperatures. Features a TCG of ±1.6% low-temperature drift, ensuring long-term stable and precise measurement performance in complex climates such as highlands, deserts, and coastal regions.

Case Study:

During routine summer inspections at a 100MW ground-mounted solar farm in Northwest China, suboptimal overall power generation efficiency was identified. Following the installation of CHIPSENSE AN3V current sensors on the combiner boxes, the monitoring system detected that the current in the second string of the fifth combiner box in Zone 12 consistently fell 25% below the average value.

On-site investigation: Oxidation of connectors caused increased contact resistance.

Post-remediation: The string's output returned to normal levels, boosting the plant's monthly generation by approximately 0.8%—a seemingly minor improvement, yet for a hundred-megawatt facility, this translates to tens of thousands of additional kilowatt-hours generated each month. CHIPSENSE current sensor play an important role in it.

Precautions:

Selection: Based on the string's maximum short-circuit current (Isc) multiplied by a 1.25 safety factor, select the IPM range. For example, if Isc=12A, an IPM ≥15A is required, fully covered by AN3V 80 PB55 current sensor of CHIPSENSE.

Installation: Primary busbars must be connected in the direction of the arrows to ensure correct output polarity;

System Integration: VOUT provides differential output (±2V). Use with an isolated ADC or op-amp for monitoring system integration;

Environmental Suitability: Creepage distance >8mm meets 600V reinforced insulation requirements (IEC 61800-5-1), suitable for high-altitude/high-humidity regions.

Conclusion

Outstanding domestic sensors such as the AN3V series current sensor from CHIPSENSE, with their SMT soldered integration, precise measurement capabilities, and safety isolation features, perfectly align with the core requirements of smart combiner boxes for multi-channel current monitoring, efficient operations and maintenance, and high reliability. They provide critical technical support for enhancing efficiency, reducing costs, and ensuring safety in photovoltaic power stations.

Naturally, the operations and maintenance of photovoltaic power stations do not rely on any single magical component, but rather on collectable data + executable processes + implementable tools.

CHIPSENSE current sensors is a good choice. That’s because it not only prioritise product safety and significantly reduce costs, but also deliver high operational efficiency for customers.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806