In recent years, China's new energy vehicle market has been booming, with even major internet companies venturing into the new energy vehicle industry. The number of electric vehicles is rapidly increasing, and the demand for charging stations is experiencing explosive growth, with 'every 5 cars having 2 charging stations.' The safety of charging stations has also become a matter of widespread public concern. The National Energy Administration organized the formulation of the mandatory national standard GB39752-2024 'Safety Requirements for Electric Vehicle Power Supply Equipment,' which will be officially implemented in August 2025. The new standard clearly stipulates that charging stations must be equipped with leakage protection functions to prevent electric shock accidents. The following text focuses on how current sensors based on magnetic flux gate technology can be applied to DC leakage protection for charging stations.

Electric vehicle charging pile

Electric vehicle charging piles are devices that provide electric energy replenishment for new energy vehicles. They are divided into alternating current (AC) charging piles and direct current (DC) charging piles based on charging type. AC charging piles are generally installed in private garages and classify as slow charging. DC charging piles are usually installed in public places, such as commercial parking lots and highway service areas, to meet the demand for fast charging. According to data from the China Electric Vehicle Charging Infrastructure Promotion Alliance, as of the end of July 2025, the total number of electric vehicle charging infrastructure (units) in China reached 16.696 million, a year-on-year increase of 53%. China has built the world's largest electric vehicle charging network.

Plan for installing leakage protection devices for charging piles

Leakage current refers to the phenomenon where electric current flows through unintended paths, which can lead to electrical shock accidents or electrical fires. The main reasons for leakage current in electric vehicle charging stations are:

• Aging equipment and circuit issues

After long-term use of charging piles, the circuit may cause leakage due to poor contact, damaged insulation, or aging components, triggering the leakage protection switch to trip.Some charging piles have issues such as improper grounding and abnormal insulation, which prevent timely disconnection of power during leakage, increasing the risk of electric shock.

• Environmental and installation factors:

A humid environment or damp cables can easily lead to short circuits, while high temperatures or overloads can also cause protection devices to activate. Improper installation (such as incorrect cable splicing or incorrect selection of leakage protection) may result in loose connections, increased resistance, and consequently heating up or even fire.

• Potential Dangers of High-Voltage Fast Charging

The voltage of DC fast charging piles can reach 750V. If the grounding fails or there is an insulation fault, the consequences of leakage can be more severe.When the charging gun head is damaged or the lock device fails, the exposed high-voltage parts may directly cause electric shock.

The new regulation of "Safety Requirements for Electric Vehicle Power Supply Equipment", section 5.3, mandates that charging stations must be equipped with a Residual Current Device (RCD) or an equivalent monitoring device. The rated residual operating current IΔn of the RCD (device) should not exceed 30mA, and strict requirements are imposed on both DC/AC charging equipment. Below is a comparison of the leakage protection schemes for charging stations:

| Solution | Principle | Advantages | Disadvantages |

| Type A RCD | Detection of alternating current residual current | Low cost, mature technology | Unable to detect DC leakage/pulsating DC leakage |

| Type B RCD | Detection of alternating current and direct current residual current | Comprehensive coverage of leakage current types | High cost, bulky size, high action threshold |

| Insulation Monitoring Device | Real-time monitoring of insulation resistance | Suitable for DC systems | Requires coordination with circuit breakers, slow response time |

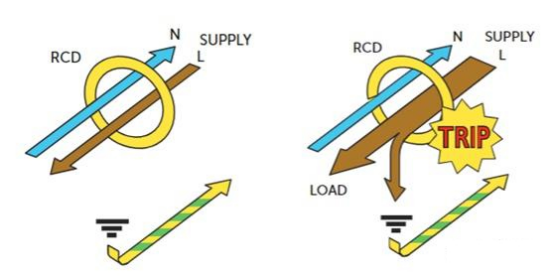

The Residual Current Device (RCD) is a safety device used in charging piles to monitor leakage current and quickly cut off the power supply. Its core function is to prevent electric shock, equipment damage, and electrical fires. The working principle is to detect the current difference between the live wire (L) and the neutral wire (N). When the difference exceeds a threshold (such as 30mA), it cuts off the circuit within milliseconds.

There will be DC leakage current in the communication circuit:

1)When a grounding fault occurs on the AC input side of the power grid, it will cause the appearance of a sinusoidal residual current with the same frequency as the power grid;

2)A grounding fault occurs in the AC/DC rectifier section: this will result in the appearance of pulsating DC residual current;

3)A grounding fault occurs in the DC/DC converter section: this will lead to the appearance of smooth DC residual current.

DC leakage has the following characteristics:

Low current: Usually in the level mA , but it is persistent and can accumulate into safety hazards.

High concealment: Traditional RCDs cannot detect it; early warning requires specialized sensors and algorithms.

Moreover, the RCD is ineffective for smooth DC leakage, making it easy to overlook hazards; additionally, GB 39752—2024 explicitly requires:

DC charging piles need to monitor leakage current in real-time, with an action threshold of ≤6mA.

Multi-circuit piles need to be independently monitored to prevent sticking faults.

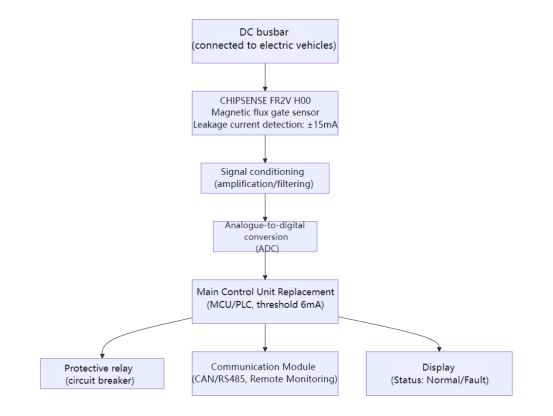

Therefore, here is a high-precision leakage current monitoring solution: a current sensor based on magnetic flux gate technology, used for precise measurement of DC residual current.

Application Scenarios

Leakage monitoring for DC charging pile busbars.

Isolation of multiple vehicle pile circuits and leakage alarms.

Framework diagram of the DC leakage current detection system for charging piles

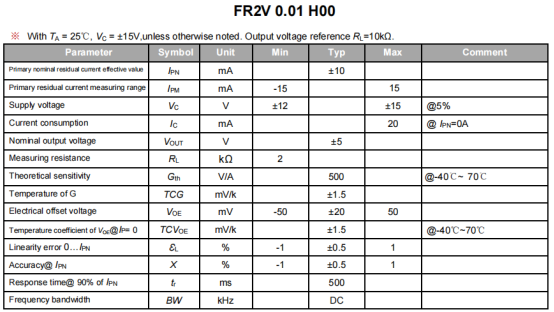

Currently, there are many high-precision, wide range, wide frequency response, high stability, and low temperature drift magnetic flux gate current sensors domestically, all 100% domestically produced and compatible with mainstream international sensor models. Taking CHIPSENSE FR2V series current sensor as an example, it includes models such as FR2V 0.01 H00, FR2V 0.02 H00, FR2V 0.05 H00, FR2V 0.10 H00, FR2V 0.20 H00, and FR2V 0.30 H00, with a residual current measurement range of 0.01-0.3A. The design highlights of CHIPSENSE current sensors that comply with the new regulations are:

High sensitivity:

Detects small DC leakage (such as early insulation aging), CHIPSENSE current sensor meeting the monitoring requirement of ≤6mA.

Electrical isolation:

Creepage distance of 7.2mm between the primary and secondary sides, CHIPSENSE current sensor in compliance with reinforced insulation standards (IEC 61800-5-1).

Fast response:

Outputs voltage signals within 500ms, combined with the control system for instantaneous power interruption.

Comparison of CHIPSENSE FR2V H00 current sensor with traditional solutions

| Solution | CHIPSENSE FR2V H00 | Traditional RCD | Type B RCD |

| Detection Range | ±15mA/±75mA | 30mA and above | 30mA and above |

| Response Time | ≤500ms | ≥20ms | ≥20ms |

| Accuracy | ±0.5% | ±10% | ±10% |

| Applicable Current Type | DC + AC | AC only | DC + AC |

| Cost | Medium | Low | High |

| Volume | Small | Small | Large |

| Early Warning | Supported | Not supported | Not supported |

System Integration Plan

Coordination with RCD: CHIPSENSE FR2V monitors leakage current → outputs analog signals → triggers RCD or alarm, achieving dual protection of early warning by FR2V fluxgate current sensor of CHIPSENSE and emergency power-off by RCD.

Multi-circuit monitoring: Each charging circuit is equipped with one CHIPSENSE FR2V current sensor , allowing for independent leakage protection.

Practical Application Case

Case 1: Leakage Monitoring Upgrade of a DC Fast Charging Station

Background: A certain charging station's DC fast charging piles frequently experience leakage due to insulation aging, which traditional RCDs cannot detect.

Solution:

Install CHIPSENSE FR2V 0.05 H00 current sensor on the DC bus to monitor leakage current in real-time.

Set a 6mA warning threshold, triggering a relay to cut off power when exceeded.

Effect:

Leakage fault detection rate increased by 95%.

Average response time reduced to within 1 second.

Case 2: Insulation Monitoring of Photovoltaic Energy Storage System

Background:

The insulation on the DC side of the photovoltaic energy storage system has deteriorated, leading to ground leakage and potential safety hazards.

Solution:

Install CHIPSENSE FR2V 0.10 H00 current sensor on the DC bus. - Combine with an insulation monitoring device for dual protection.

Effect:

Insulation fault warning time advanced by 24 hours.

Prevented 3 potential electric shock incidents.

Conclusion

Magnetic flux gate sensors provide an accurate solution for leakage monitoring of DC charging piles due to their high precision, fast response, and early warning features. Combined with traditional RCDs, they can achieve dual protection, meeting safety standard requirements such as GB 39752—2024. For charging pile operators and equipment manufacturers, CHIPSENSE FR2V H00 current sensor is not only a necessary choice for compliance but also a solid guarantee of safety.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806