Recently, WTO statistics officials stated at a press conference for the WTO Global Trade Outlook report that in the first half of 2025, Asia accounted for two-thirds of global artificial intelligence trade growth. The wave of intelligence is reshaping various industries at an unprecedented pace. AI technology is also moving from the consumer end to the industrial end, deeply integrating with traditional sectors such as energy and industry. In September 2025, the National Development and Reform Commission, together with the National Energy Administration, issued the "Implementation Opinions on Promoting High-Quality Development of 'Artificial Intelligence' in Energy," clearly proposing to initially establish an innovative integration system for energy and artificial intelligence by 2027, and by 2030, strive to make AI energy technology reach world-leading levels. 'AI energy' has risen to the level of a national strategy. In this transformation, as the 'main force' of the energy revolution, how can energy storage systems leverage AI to achieve intelligent upgrades? CHIPSENSE current sensor also will offer some solutions.

As a key node in the energy Internet, energy storage systems play an important role in improving efficiency, safety, and economic value through their intelligent development. The AI-driven battery management system (BMS) is becoming a crucial direction for enhancing the performance of energy storage systems by optimizing charging and discharging strategies and strengthening safety monitoring capabilities. The first step toward intelligence is 'precise perception,' because AI decisions rely on high-quality data, which depends on real-time sensor monitoring. Current measurement is the lifeline of BMS data. CHIPSENSE current sensors also for BMS.

Definition

A Battery Management System (BMS) is the core control system of a battery pack. By performing functions such as real-time monitoring, state evaluation, charge and discharge control, thermal management, balancing management, and fault diagnosis, it ensures the safe and efficient operation of the battery pack. It acts like the "brain" of the battery pack and is crucial for improving the lifespan, safety, and efficiency of energy storage systems.

The BMS works in coordination with the Energy Management System (EMS) and the energy storage converter (PCS) to achieve intelligent control of the charging and discharging processes.

One of the core functions of the BMS is status monitoring and data acquisition, which involves real-time collection of parameters such as voltage, current, and temperature of individual cells or battery packs. Key indicator calculations include: SOC (State of Charge): estimating the remaining battery capacity to guide charging and discharging strategies; SOH (State of Health): evaluating the battery's aging condition. Other functions are not discussed here due to space constraints; please refer to relevant materials if needed.

BMS Requirements for Current Monitoring

Current monitoring is the foundation for the BMS to achieve precise control and protection, with specific requirements as follows:

High Accuracy:

The accuracy of current monitoring directly affects the accuracy of SOC estimation and charge-discharge control.

Typically, the current monitoring accuracy is required to be within ±0.5% to ensure the reliability of battery management.

Dynamic Response:

Battery current can change rapidly, and the BMS current monitoring system must be fast enough (usually at the millisecond level) to capture dynamic current changes.

The maximum expected slew rate (bidirectional) needs to be known to ensure monitoring accuracy is maintained during rapid current changes.

Anti-Interference Capability:

The current detection signal is low voltage and must be connected to a high-impedance input, making it very sensitive to noise.

Appropriate shielding and grounding techniques should be used, and twisted-pair connections should be employed to minimize current mode interference.

Temperature Compensation and Calibration:

The zero offset error of the current sensor changes with temperature, which may vary depending on the device, and may also change over time.

Temperature compensation and adaptive calibration of the current sensor are required to address sensor aging issues.

Support for Multiple Ranges:

The application current in energy storage systems has a wide dynamic range, requiring support for current monitoring across multiple ranges.

When the maximum measurement range is exceeded, the smaller range will saturate, and a larger range should then be used. Special attention should be paid to the switching points between low-range and high-range sensors.

Fault Diagnosis Capability:

Capable of detecting faults in the current monitoring system, such as sensor failures, open circuits, or short circuits.

When a fault occurs in the current monitoring system, the BMS should promptly take protective measures to prevent damage to the battery.

Insulation and Safety:

High-voltage energy storage systems (such as 1500V DC side) have strict requirements for isolation voltage withstand (e.g., 3.8kV AC/1min) and long-term reliability.

Standard compliance: Certifications such as IEC61800-5-1 and IEC62109-1 are entry requirements for the industrial-grade energy storage market. All CHIPSENSE current sensor are meets these standards.

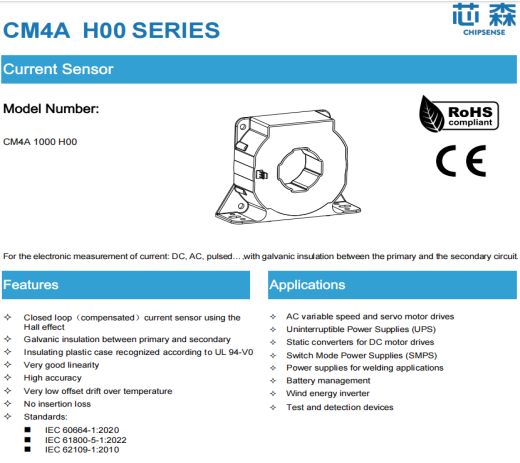

Regarding the above requirements, general Hall open-loop current sensors cannot meet the needs of BMS systems. Closed-loop sensors outperform open-loop sensors in terms of accuracy and dynamic performance and are fully capable of handling applications in BMS systems. There are many high-precision current sensors available on the market, and domestic sensors can now compete with internationally renowned brands, with some key parameters even surpassing those of major international brands, such as the CM4A series hall closed-loop current sensors from CHIPSENSE.

The CM4A series current sensors are independently developed by CHIPSENSE. CHIPSENSE uses the hall closed-loop (compensation) principle, detecting the magnetic field generated by the primary current through Hall elements and generating a compensation current through the secondary coil, achieving electrical isolation between the primary and secondary sides. CHIPSENSE current sensors are customers’ first choice.

Advantages of CHIPSENSE CM4A current sensor in Energy Storage BMS

High Accuracy: ±0.3% accuracy meets BMS's high-precision current monitoring requirements. The 0.3% error margin can improve SOC estimation accuracy and reduce energy waste. CHIPSENSE current sensor has very high requirements for accuracy.

Excellent Linearity: Linear error of 0.1%, ensuring precise measurements.

Fast Response: Response time of only 0.5μs, meeting BMS real-time monitoring needs.

Wide Frequency Band: 150kHz bandwidth can accurately capture current changes and supports real-time adjustment by AI algorithms.

Wide Temperature Range: Operating temperature from -40℃ to 85℃, suitable for various environmental conditions.

Safety Compliance: CHIPSENSE current sensor are certified IEC61800-5-1 / IEC62109-1 , meeting CAT III PD2 level insulation requirements.Practical Significance of 16kV Impulse Withstand Voltage and 3.8kV AC Isolation Voltage: Ensures protection of BMS hardware in case of lightning surges or short-circuit faults.

Electrical Safety Characteristics of CHIPSENSE current sensors:

AC isolation withstand test RMS @ 50Hz, 1min: 3.8kV

Transient withstand voltage 1.2/50μs: 16kV

Electrical clearance distance (between primary and secondary): 19.6mm

Creepage distance (between primary and secondary): 20.6mm

These insulation characteristics are crucial for the safety of the BMS system.

Typical Application Scenarios of Current Sensors in BMS

Charging and Discharging Management: Monitor current in real time and adjust the switching states of power devices (such as IGBTs).

Fault Diagnosis: Analyze current wave-forms to identify signs of internal battery short circuits or aging.

Energy Measurement: Accurately measure charging and discharging energy, supporting peak-valley electricity price arbitrage and demand-side response.

System topology diagram of CHIPSENSE CM4A hall current sensor in energy storage system

In AI-driven energy storage systems, CHIPSENSE CM4A closed-loop hall current sensor provides the BMS with reliable current monitoring data, thanks to its ±0.3% accuracy, 0.5μs response time, and 150kHz bandwidth, aiding in the achievement of:

Refined energy management: Improve SOC estimation accuracy and reduce energy waste.

Real-time overcurrent protection: Supports millisecond-level control to ensure battery safety.

Intelligent optimization: Provides high-quality data input for AI algorithms to enable dynamic adjustment.

Conclusion:

With the continuous growth of AI trade in Asia, more AI algorithms will be applied in the energy storage field. High-performance sensors like CHIPSENSE CM4A current sensor will serve as the key bridge connecting the physical world and the intelligent digital world, jointly building a safer, more efficient, and smarter future energy system. CHIPSENSE current sensor will keep developing in the future.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806