With the popularity of smart homes, in addition to common smart lighting, smart vacuum cleaners have become the 'cleaning assistants' in modern households, especially for the lazy. However, most smart vacuum cleaners available on the market are not that smart when they are 'working': they can easily get stuck in corners and become immobile. This high-intensity work can lead to motor overload, increased energy consumption, and even safety hazards such as circuit shorts. How can we ensure that vacuum cleaners are both efficient and safe? Besides high-end machines that come with LiDAR and cameras, there is another key player that works quietly – the current sensor. This article will delve into the core role of current detection in vacuum cleaners, compare different technical solutions, and provide a detailed analysis of a typical sensor chip and its applications. There is an case from CHIPSENSE current sensor.

Safety hazards of the sweeping machine

1.Motor overload: The main brush, side brush, or drive motor may get stuck due to foreign objects or tangled hair during the cleaning process, leading to a surge in current and damaging the motor.

2.Battery safety: Overcurrent, overcharging, or over-discharging during the charge-discharge process of lithium batteries can shorten battery life and even trigger safety accidents.

3. Circuit faults: Short circuits or poor contacts may cause the equipment to suddenly lose power or burn out.

Why does a robot vacuum need accurate current sensing?

Before discussing 'how', we first need to understand 'why'. For a robot vacuum, precise current detection is essential, and it directly relates to three core issues:

1. Battery safety and endurance management (BMS): How to accurately calculate the remaining charge (SOC) to prevent overcharging and over-discharging? How to immediately cut off power when the motor gets stuck and causes a sudden surge in current, preventing the battery from overheating or even catching fire?

2. Intelligent control and protection of motors: How can a vacuum cleaner automatically increase torque (suction or brush power) when encountering a thick carpet? How can it determine if the main brush is entangled with hair (load change), thus triggering a reverse or alarm?

3. System energy consumption optimization: How to precisely control power output in different working modes (silent, standard, powerful) to achieve optimal energy efficiency?

All these questions rely on real-time, high-precision, isolated measurement of motor current and battery current. And CHIPSENSE current sensors meet this needs. These issues are the problems that CHIPSENSE current sensor is dedicated to solving.

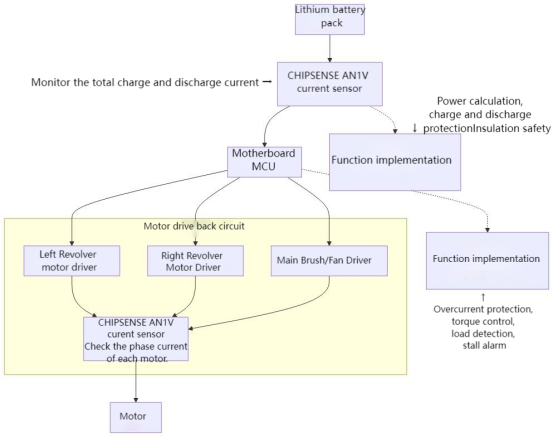

The Electrical Architecture and Current Detection Points of Vacuum Cleaners

The typical electrical architecture of a vacuum cleaner is simplified as follows, where the core task of the current sensor is to accurately measure the current at these points and convert it into a voltage signal that can be read by the MCU:

Comparison of Solutions: Hall Current Sensors vs Traditional Solutions

In engineering implementation, current detection mainly has two classic technical paths: shunt resistors based on Ohm's law and Hall effect sensors based on the principle of magnetic induction. There are significant differences in principles, performance, and applications between the two.

1)Shunt Resistor Solution

Principle:

Its core is Ohm's Law (V = I×R). A precision, low-resistance resistor (shunt) is connected in series to the current path to be measured, measuring the small voltage drop generated across that resistor when current flows through it. This millivolt-level voltage signal is then amplified by an amplifier, and the current value is calculated by the ADC of the MCU.

Advantages:

1.Low cost: The cost of a single resistor element is extremely low.

2.High precision: Very high measurement accuracy can be achieved at room temperature.

3.High bandwidth: Fast response speed with no delay, suitable for current detection at extremely high frequencies.

Disadvantages:

1.No electrical isolation: The measuring circuit shares a ground with the high-voltage bus being measured, posing a risk of high voltage leaking into the low-voltage control circuit.

2.There is ohmic loss: The loss is I²R. In high current applications, the resistor itself will heat up, not only causing energy waste but also affecting measurement accuracy due to temperature drift, which may even require additional thermal management.

3. High layout requirements: Measuring millivolt-level signals is easily affected by noise from other power circuits on the PCB, thus imposing strict requirements on layout and routing.

1)Hall Effect Current Sensor Scheme (taking CHIPSENSE AN1V PB511 series current sensor as an example)

Principle:Utilizing the Hall effect, the magnetic field generated by the current is concentrated onto the Hall chip through the magnetic core inside the sensor. The chip outputs a voltage signal proportional to the magnetic field strength, thereby indirectly measuring the current. Signal conditioning and amplification have been completed internally within the sensor.•

Advantages:

a.Natural electrical isolation: The primary side (current path) is insulated from the secondary side (signal output) (CHIPSENSE AN1V current sensor isolation withstand voltage up to 4.8kV), completely eliminating common ground issues, resulting in high system safety.

b.Nearly zero loss: Non-contact measurement, with extremely low primary side resistance (the Rp of CHIPSENSE AN1V current sensor is only 100μΩ), generating almost no heat and not affecting the measured circuit.

c.Easy to integrate: Provides modulated voltage output (such as Vout=2.5V±ΔV for AN1V), simple interface directly connecting to the MCU's ADC, greatly simplifying system design. The current sensor design of CHIPSENSE meets customer’s need.

Disadvantages:

a.High cost: The cost of a single sensor is higher than that of a shunt resistor.

b.Temperature drift: The characteristics of the Hall element and magnetic core can be affected by temperature. Although the chip internally compensates, its accuracy and temperature drift indicators are usually inferior to those of comparable shunt solutions.

c.Limitations on bandwidth and response time: Although CHIPSENSE AN1V current sensor bandwidth reaches 250kHz, which is sufficient for most applications, it still cannot be compared to passive shunt resistors. There is also a microsecond-level response delay.

Conclusion:

For smart vacuum robots, characteristics such as battery power supply (sensitive to losses), compact space, and the presence of high voltage motor circuits (high safety requirements) make the advantages of Hall effect current sensors (isolation, low loss, easy integration) precisely address their pain points, thus becoming a more ideal solution than shunt resistors. CHIPSENSE AN1V series current sensor is a typical product designed to meet such applications.

Solution Analysis:

Technical Characteristics of CHIPSENSE AN1V Series Current Sensor

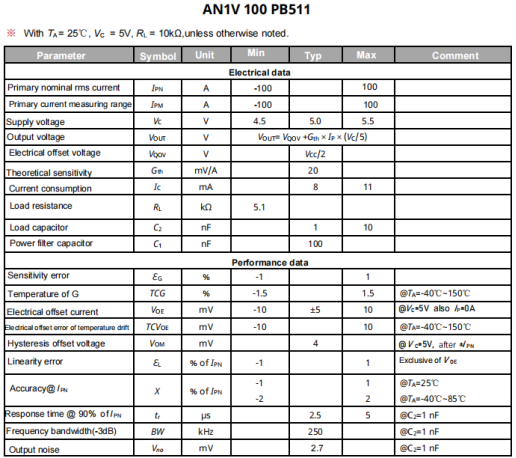

Taking CHIPSENSE AN1V PB511 series current sensor as an example, it is a micro Hall current sensor based on ASIC chip technology, achieving small size packaging and 100% domestic production. This series includes multiple models with a range from 50 to 300A. From its public specification sheet, we can clearly see how it meets the needs of sweeping machines.

1.Core working principle:

The output follows the formula: Vout = Vcc/2 Gth × Ip × (Vc/5). Here, Vcc/2 (approximately 2.5V) is the zero point voltage at zero current. When forward current flows, the output voltage increases; when reverse current (such as during charging) flows, the output voltage decreases. This design is very suitable for bi-directional current measurement at the MCU's ADC interface.

2.Key performance parameters (taking CHIPSENSE AN1V 100 PB511 model current sensor as an example):

Measuring range: ±100A, covering the operational range of the sweeper motor.

Power supply voltage: 4.5V - 5.5V, perfectly compatible with the system's MCU power supply.

Bandwidth: 250kHz, sufficient to accurately track the high-frequency PWM current waveform driven by the BLDC motor, ensuring the real-time nature of the control loop.

Accuracy: Overall accuracy better than ±2% across the full temperature range (-40℃ ~ 85℃), providing a basis for battery calculation and precise control.

Response time: ≤5μs, enough to send a signal to the MCU shortly after an overcurrent event to initiate the protection mechanism.

3.Safety and Reliability Design:

High Isolation Voltage: The primary and secondary sides of this current sensor can withstand 4800Vrms/50Hz/1min, far exceeding any potential pressure differential in the sweeping machine system, completely eliminating the risk of high voltage entering the low voltage control circuit.

Compliance with Safety Standards: Meets standards such as IEC 61800-5-1, satisfying the stringent safety requirements for household appliances.

Flame-Retardant Shell: The materials comply with UL 94-V0 rating, providing fire safety assurance.

Application Scenario: How Hall Sensors Protect Robotic Vacuum Cleaners?

1.Motor Overload Protection

Real-time Monitoring: Hall sensors monitor the motor current in real time and immediately trigger a protection mechanism to stop the motor or reverse to clear obstructions if abnormal current increases (such as stalling).-

Extended Lifespan: Prevents long-term motor overload to extend its lifespan.

2.Battery Management

Charge and Discharge Protection: Monitors battery charge and discharge current to prevent overcharging/over-discharging, ensuring battery safety and lifespan.

Energy Optimization: Real-time calculation of remaining power to optimize battery life and charging strategy.

3.Fault Diagnosis: Overcurrent Protection:

Immediately cuts off power supply when a short circuit or overcurrent is detected to avoid equipment damage.

Predictive Maintenance: Analyzes current fluctuations to predict potential failures in the motor or battery for proactive maintenance.

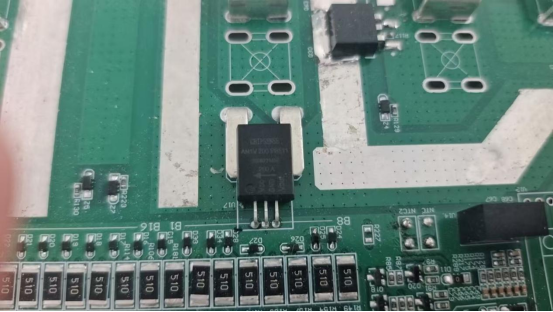

Specific technical proposal: Integration of AN1V 200 PB511 in the sweeping machine

1.Circuit design

Connect the sensor's IP and IP- in series to the main current loop of the motor or battery.

VOUT connects to the ADC pin of the MCU to sample current data in real-time.

Add decoupling capacitors (100nF) and filtering capacitors (1nF~10nF) to ensure signal stability.

2.MCU Algorithm

By sampling the VOUT voltage through ADC, calculate the actual current value: Current (A) = (VOUT - 2.5V) / (0.01 × VCC)Set a current threshold, and trigger the protection mechanism when it exceeds the threshold.

3.Safety Standards

The sensor complies with IEC 61800-5-1 and IEC 62109-1 standards to ensure high voltage safety and insulation reliability.

Risk Warning: Limitations of Hall Sensors

Magnetic Field Interference: Strong magnetic field environments may affect measurement accuracy, requiring reasonable wiring.

Temperature Drift: Zero point drift may occur under extreme temperatures, necessitating regular calibration.

-Cost: Compared to traditional solutions, Hall sensors are slightly more expensive, but they offer excellent cost-performance ratio.

Conclusion: Hall Current Sensors, the 'Guardians' of Robotic Vacuum Safety

ASIC-based Hall current sensors (like CHIPSENSE AN1V 200 PB511 current sensor) have become the core components for the safety protection of smart robotic vacuums due to their advantages such as high precision, fast response, and non-contact measurement. They not only monitor current in real-time and prevent overload but also optimize energy efficiency and extend the lifespan of devices, providing users with a safer and smarter cleaning experience.

Keywords: Hall current sensor, smart robotic vacuum, motor protection, battery management, ASIC technology, overcurrent protection, safety monitoring.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806