The European Carbon Market Access (CBAM) is a carbon border adjustment mechanism implemented by the European Union to combat climate change. It aims to impose a carbon price on imported high-carbon-emitting products, comparable to that of the EU Emissions Trading Scheme (ETS), to prevent carbon leakage and promote global emissions reductions. Currently, the CBAM has entered the mandatory reporting phase, requiring photovoltaic product exports to provide embedded carbon emissions data. Starting in 2026, CBAM certificates will be required, gradually replacing free quotas and imposing a carbon tariff. This means that all products exported to Europe, including photovoltaic modules, inverters, and energy storage devices, must provide a Life Cycle Carbon Accounting (LCA) and ensure that the data is verifiable and traceable.

In other words, the future of photovoltaic power generation will no longer simply focus on "how much electricity is generated" but will also need to answer a more complex question: "How much CO2 is emitted behind this kilowatt-hour of electricity?" In carbon footprint accounting systems, the accuracy of all energy flow and consumption data ultimately determines whether a company can pass CBAM compliance reviews. CHIPSNESE current sensor also found this.

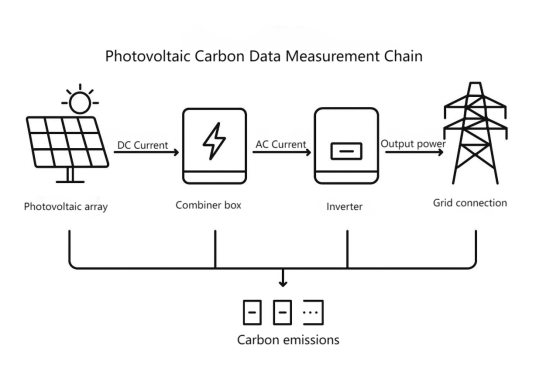

At the lowest level of the energy data chain, the performance and stability of current sensors are becoming a key factor in determining the credibility of carbon data.

The underlying logic of carbon accounting: From energy flow to carbon emissions

The core logic of carbon footprint accounting is based on the multiplication of energy conservation and emission factors:

CO2=E×EF

Where E represents energy consumption (usually calculated from current, voltage, and time), and EF is the emission factor. If measurement data such as current and voltage are skewed, the final carbon emissions results will be proportionally distorted. Therefore, the accuracy of carbon footprint accounting data depends on the precision, stability, and traceability of the underlying measurement chain. CHIPSNESE current sensors meet these requirements.

Carbon cost accounting has relatively high requirements. Carbon footprint accounting covers the entire process from raw materials to manufacturing. The EU has strict accounting requirements for indirect emissions (such as electricity consumption). Photovoltaic power station operating data (such as power generation efficiency, energy consumption, etc.) is the basis for accounting. Taking polycrystalline silicon cells as an example, for every 1% decrease in power generation efficiency, the carbon footprint increases by about 0.5%. If data collection is not accurate enough, it may lead to deviations in carbon footprint reporting and face high carbon tariffs or export restrictions.

The key role of current sensors in calculating the carbon footprint of photovoltaic power plants

To address the CBAM tariffs, in addition to adopting low-carbon technologies, such as replacing traditional silicon with granular silicon and using TOPCon cells to reduce unit emissions, sensors also play a key role in carbon footprint calculation, primarily through optimizing energy efficiency and reducing emissions. For example, current sensor errors directly affect inverter efficiency measurements, which in turn impact carbon footprint calculations. Inadequate sensor accuracy leads to deviations between the sampled current and the actual value. According to relevant data, a 2% MPPT tracking error can result in a 3% reduction in annual power generation and a 1.5% increase in carbon footprint. By detecting anomalies in the current waveform collected by current sensors (such as imbalance and glitches), hidden cracks or hot spots can be quickly located, avoiding power generation losses and indirect carbon emissions caused by module failure.

Furthermore, carbon footprint calculation is essentially a precise accounting of energy and material flows. In a photovoltaic power plant, the following power links must be monitored in real time:

| Links | Calculation objectives | Key monitoring parameters: |

| PV array → combiner box | Module output efficiency, mismatch loss | DC current and voltage; |

| Combiner box → inverter | Conversion efficiency,circuit loss | Bus current and voltage; |

| Inverter → grid connection point | Active/reactive power, harmonic content | AC current and voltage; |

| Energy storage system | Charge/discharge efficiency, energy return | Bidirectional current and voltage |

These parameters are measured through high-precision energy flow measurements using current sensors. The current sensors here act as "physical collection points for carbon data" in photovoltaic and energy storage systems, providing basic input for the carbon accounting system.

CBAM's Technical Requirements for the Measurement Chain

The EU Carbon Border Mechanism requires companies to submit a "Measurement Chain Integrity Statement" (MCIS), which includes the measurement equipment model, accuracy level, calibration cycle, drift data, and a verification report.

This means:

The measurement equipment must have an accuracy of ±1% or better;

The output characteristics must remain consistent over long periods of operation;

The equipment and its data must be reproducible and auditable by a third party.

The characteristics of closed-loop Hall effect current sensors (high precision, low temperature drift, and strong isolation) precisely meet this requirement.

They can provide authentic, repeatable raw data for carbon accounting in photovoltaic combiner boxes, energy storage converters, inverter systems, manufacturing test benches, and other applications.

Advantages of Closed-Loop Hall Effect Current Sensing Technology

In complex energy systems such as photovoltaics and energy storage, energy flow is often bidirectional and non-sinusoidal. Traditional shunt resistance measurements are susceptible to interference in high-voltage or high-frequency environments, making it difficult to maintain long-term accuracy.

Closed-Loop Hall Effect Current Sensing technology offers the following advantages:

High linearity and low temperature drift: The Linearity error of CHIPSENSE current sensors can be controlled to ±0.1%, making it suitable for long-term energy consumption monitoring.

Wide bandwidth and fast response: Bandwidth reaches hundreds of kilohertz, accurately reflecting dynamic energy changes in inverters and energy storage systems.

Electrical isolation: CHIPSENSE current sensors meet the requirements of standards such as IEC 60664-1 and IEC 61800-5-1, making it suitable for high-voltage bus-side measurements.

Long-term repeatability: Stable output signal facilitates traceability and calibration records within the measurement chain.

These characteristics make it a reliable "energy data collection unit" in the carbon accounting system, providing reliable input for subsequent carbon emission calculations.

CHIPSENSE CR1A Current Sensor Technical Features: Providing Compliance-Level Accuracy for Carbon Data

The CR1A H00 series is a Hall-effect-based, closed-loop (magnetically compensated) current sensor independently developed by CHIPSENSE. It can measure DC, AC, and pulsed currents. CHIPSENSE CR1A current sensor key technical parameters are as follows:

| Parameters | Value | Compliance Benefits |

| Linearity error, | ≤ ±0.1% of IPN | Supports±1% data accuracy required by CBAM |

| Overall accuracy, | ≤ ±0.5% | Suitable for lifecycle carbon accounting and energy consumption statistics |

| Temperature drift, | ±0.2mA(-40~85℃) | Ensures stable energy consumption data throughout the year |

| Response time, | ≤1 μs | Capable of capturing power fluctuations and energy transients |

| Bandwidth, | 200 kHz | Supports inverter high-frequency PWM signal measurement |

| Insulation withstand voltage, | AC 3 kV / 1min | Meets IEC 60664-1 and 62109-1 standards |

| Creepage distance, | 15 mm | Safe isolation, anti-interference, and overvoltage protection |

| Operating temperature | -40~85℃ | Suitable for outdoor photovoltaic power station operating environments |

These performance indicators enable CHIPSENSE CR1A current sensors to stably support energy flow collection, equipment efficiency assessment and emission factor calculation in the carbon accounting system.

How CHIPSENSE CR1A Current Sensors Supports CBAM Carbon Compliance

1. Providing Verifiable Raw Energy Consumption Data

CBAM filings require the provision of calculations for equipment energy consumption, efficiency, and emission factors. CHIPSENSE CR1A's high-precision current data can be combined with voltage signals to generate power and energy curves, providing a direct measurement basis for LCA models and meeting the EU ISO 14067 "measurement-based" data credibility requirements.

2. Supporting "Measurement Chain Integrity" Requirements

The EU CBAM document explicitly requires companies to submit a Measurement Chain Integrity Statement.

CHIPSENSE CR1A's closed-loop current sensor architecture, fixed turns ratio, and factory calibration parameters ensure traceability and repeatability of its signals. This allows it to be incorporated into a company's internal measurement traceability system and recognized as a "first-tier sensing unit" by carbon audits.

3. Reduce Carbon Emission Calculation Errors

Assuming a 100 MW photovoltaic power plant generates 130 million kWh of electricity annually, a 1% error in current measurement would result in a carbon accounting error of approximately 60 tons of CO₂.

The CR1A's ±0.5% accuracy of CHIPSENSE current sensor effectively reduces error accumulation, ensuring that carbon emission calculations remain within the CBAM tolerance range.

Conclusion: Measurement is the starting point for carbon compliance.

The key to CBAM isn't who has the lowest emissions, but whose carbon data is more reliable. Achieving this goal requires starting with the underlying measurement process, ensuring that every step of the energy flow is accurately recorded and verifiable. Closed-loop Hall effect current sensing technology, with its high precision, strong isolation, and traceability, provides a reliable physical foundation for carbon footprint accounting. CHIPSENSE has been providing customers with current sensosrs for different applications.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806