Have you ever wondered or encountered this question: Why do different inverters have different power generation efficiencies under the same lighting conditions? The answer lies in MPPT, or Maximum Power Point Tracking (MPPT). Accurate current sensing is the foundation for MPPT algorithm optimization. How can we improve MPPT efficiency through high-precision current sensing technology, thereby increasing the power generation and operating returns of photovoltaic systems? Let's discuss this topic together.

The photovoltaic inverter is the core device of a photovoltaic power generation system, responsible for converting the direct current (DC) generated by photovoltaic panels into alternating current (AC), enabling grid-connected or off-grid power supply. The MPPT (Maximum Power Point Tracking) technology in photovoltaic inverters is a key mechanism for improving photovoltaic system power generation. It dynamically adjusts the operating voltage and current of photovoltaic panels to ensure they consistently operate at the maximum power point (MPP) on the IV curve. The core of the MPPT algorithm is to calculate the output power of photovoltaic panels (P = V×I) in real time and continuously fine-tune the operating point to find the maximum power point, ensuring that the photovoltaic panels consistently operate at their maximum power output. Therefore, the photovoltaic inverter has two core tasks: converting DC to AC and maximizing power generation.

During photovoltaic power generation, factors such as sunlight, temperature, and cloud cover can cause the output current and voltage of photovoltaic panels to fluctuate nonlinearly and constantly. Therefore, the MPPT system for photovoltaic inverters requires current and voltage sensors to provide real-time current and voltage data for power calculation and to help the MPPT algorithm find its maximum power point. According to relevant examples, under the same lighting conditions, inverters with MPPT can achieve 10%-20% higher power generation efficiency than those without.

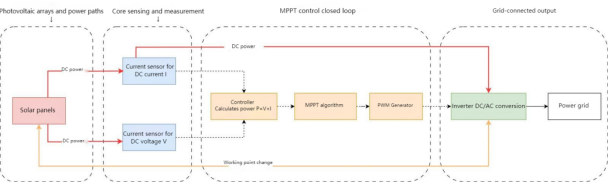

The following figure illustrates the application of sensors in an MPPT system:

High Accuracy

For MPPT algorithms, even small errors in current measurement can lead to significant deviations in power calculations. An accurate current value is essential for the algorithm to make correct decisions. Therefore, MPPT requires high-precision current sensors to provide precise current data.

Fast Response

MPPT algorithms (such as the perturbation-and-observe method and the incremental conductance method) require millisecond sampling cycles to adjust the operating point. The bandwidth of the current sensor must match the sampling frequency (typically >1kHz) to avoid phase delays that can cause tracking errors. Sensor signal processing delays (such as filtering and ADC conversion) can reduce system response speed and affect tracking efficiency in dynamic environments.

Low Power Consumption and High Reliability

Excessive sensor power consumption can reduce the system's net power generation, which is particularly critical in small off-grid systems. In outdoor environments, sensors must be resistant to aging and electromagnetic interference (EMI) to ensure long-term drift-free operation.

Insulation and Safety

High-voltage isolation: PV system voltages can reach hundreds of volts, so current sensors must provide high-voltage isolation (such as Hall-effect sensors) to ensure system safety.

Anti-interference capability: Electromagnetic interference generated by the inverter switching frequency (typically 10kHz to 100kHz) can affect current measurement, so sensors must have a good common-mode rejection ratio (CMRR).

Integration and Compatibility

Miniaturization: Modern MPPTs are often integrated within the inverter, so sensors must be small and easy to integrate into PCBs.

Digital interface: Support for digital outputs such as SPI/I2C simplifies communication with MCUs/DSPs and improves system integration.

Comparison of common technical solutions

| Solution | Advantages | Disadvantages: |

| Shunt resistor | Low cost, high bandwidth, | High power consumption, no isolation, accuracy affected by temperature; |

| Hall effect sensor | contactless, isolated, wide dynamic range, | high cost, requires calibration, temperature drift; |

| Fluxgate sensor | ultra-high accuracy (ppm level), low drift, | complex circuitry, high cost; |

| Rogowski coil | wide bandwidth, isolated | accuracy affected by wiring, requires compensation |

MPPT efficiency optimization requires current detection accuracy of at least ±1%. Closed-loop hall and fluxgate sensors are the best. Fluxgate sensors are relatively large and expensive. Here we recommend the CHIPSENSE CR1V series hall closed-loop current sensor.

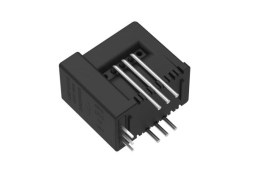

The CR1V series is a hall-effect principle-based closed-loop (compensated) current sensor independently developed by CHIPSENSE. CHIPSENSE CR1V current Sensor has a measurement range of 6-25A. Its closed-loop hall-effect principle, high precision, fast response, high isolation, and wide operating temperature range fully meet all the key requirements of the MPPT system for current detection. CHIPSENSE CR1V current Sensor is a good choice for MPPT.

The MPPT efficiency is mainly improved through the following features:

1. Accurate Current Measurement, Optimized Power Point Tracking:

High-precision current feedback: Accuracy reaches ±0.7%, with nonlinearity as low as ±0.2%, enabling accurate measurement of the PV array's output current. MPPT algorithms (such as the perturbation-and-observe method and the conductance increment method) rely on accurate current data to identify the maximum power point (MPP) on the P-V curve, minimizing power loss due to measurement errors. All of CHIPSENSE current sensors are high accuracy.

Avoiding false tracking: Low temperature drift (±0.05%/°C) and low offset voltage (±0.5mV @ 25°C) ensure stable sensor output under varying outdoor temperatures, preventing the MPPT algorithm from misjudging the power point. Fast response: The 200kHz bandwidth supports the high-frequency sampling required by the MPPT algorithm (e.g., the perturbation-and-observe method requires millisecond-level response). Tracking time: Response time is ≤1μs (at 90% of rated current) under di/dt = 50A/s, ensuring real-time adjustment under dynamic light conditions.

2. Fast Dynamic Response, Adapting to Light Changes

Real-time Adjustment: The closed-loop Hall effect sensor boasts a bandwidth of up to 200kHz and a response time of ≤1μs, enabling real-time detection of current fluctuations in the photovoltaic array caused by factors such as cloud cover and changing sunlight angles. The MPPT system can instantly adjust the operating point to maximize energy harvesting.

Reduced dynamic loss: Fast response prevents MPP deviations caused by sudden changes in illumination, improving tracking efficiency in dynamic environments (especially in overcast or cloudy conditions).

3.Wide dynamic range, compatible with diverse photovoltaic systems

Flexible Measurement Range: By adjusting the number of primary turns (e.g., 1, 2, or 3 turns), the closed-loop Hall effect sensor can cover currents ranging from microamperes to tens of amperes (e.g., CHIPSENSE CR1V 6 PB00 current sensor supports ±6A to ±18A). This adapts to PV arrays of varying sizes and ensures accurate MPPT operation in both low-light conditions (e.g., early morning) and high-light conditions (e.g., midday).

No Insertion Loss: Contactless measurement eliminates the power loss associated with shunt resistors, improving system efficiency. CHIPSNESE current sensors can do more than that.

4. High Reliability and Long-Term Stability

Anti-interference Capability: The closed-loop design suppresses external electromagnetic interference (EMI), ensuring that the current signal remains undistorted and the MPPT algorithm remains unaffected even in the inverter's high-frequency switching environment.

Long-term Stability: Low aging and drift (e.g., gain error drift of only ±0.05%/°C over temperature) ensure sensor performance remains stable over long-term operation, continuously optimizing MPPT efficiency. This is what CHIPSENSE current sensors expects.

5. Insulation Safety, Simplifying System Design

High-Voltage Isolation: The closed-loop hall effect sensor provides up to 2.5kV isolation, meeting the high-voltage safety requirements of photovoltaic systems (such as the IEC61800-5-1 standard). This eliminates the need for additional isolation circuitry, simplifies MPPT hardware design, and reduces system complexity.

Recommended Applications

Home/Small PV Systems (<5kW): The CR1V 6 PB00 is suitable for home/small commercial MPPT applications, accurately measuring low currents. Primary Turns: 1 turn: Suitable for high currents (such as the DC side of a grid-tied inverter). 2–3 turns: Suitable for low currents (such as micro off-grid systems). MPPT Algorithm Optimization: Perturb and Observe (P&O): Sampling frequency: 1–5 kHz (utilizing the sensor's 200 kHz bandwidth). Perturbation step size: 0.1–0.3 V (adjusted based on the array voltage range) to avoid MPP oscillation caused by excessive step size. Optimization: Utilizes the sensor's low temperature drift to reduce the complexity of the temperature compensation algorithm. Incremental Conductance (InC): Suitable for environments with frequent light fluctuations, leveraging the sensor's fast response (1 μs) to adjust the conductance ratio in real time.

Commercial/Medium-Sized PV Systems (5kW–50kW): CHIPSENSE CR1V 15 PB00 current sensor is suitable for three-phase inverters or parallel arrays. Primary Turns: 1: Suitable for high-power density systems. 2: Suitable for currents within the ±7.5A range. MPPT Algorithm Optimization: Hybrid Algorithm (P&O + InC): Utilizes P&O under static illumination and switches to InC under dynamic illumination, leveraging the sensor's wide bandwidth (200kHz) for fast switching. Sampling Frequency: 5–10kHz to match the sensor's response speed. Fuzzy Logic MPPT: Combines high-precision sensor data to build a fuzzy rule base for light-current-power tracking, improving tracking efficiency in complex environments.

Industrial/Large-Scale PV Power Plants (>50kW): CHIPSENSE CR1V 25 PB00 current sensor is suitable for centralized inverters or large grid-connected systems. Primary Turns: 1 (high current) or 3 (precision low current measurement). Output Stability: Accuracy as low as ±0.7%, ensuring MPPT accuracy at high power levels. MPPT algorithm optimization: Model-based MPPT: Leveraging high-precision sensor data, the PV array's I-V curve model is updated in real time to predict the MPP position. Algorithms such as Extreme Value Optimization (ES) or neural network MPPT are combined with historical data for optimization. Distributed MPPT: Each subarray is equipped with an independent CHIPSENSE CR1V current sensor to achieve localized MPPT, improving overall efficiency (especially useful in shadowed scenarios).

Expected efficiency improvement

| System Size | MPPT efficiency before optimization | MPPT efficiency after optimization | Expected improvement |

| Residential (<5kW) | 93%–95% | 96%–98% | 2%–4% |

| Commercial (5kW–50kW) | 90%–94% | 94%–97% | 3%–5% |

| Industrial (>50kW) | 88%–92% | 93%–96% | 4%–6% |

Conclusion

Closed-loop Hall sensors don't directly "generate" energy to improve MPPT efficiency. Instead, they provide high-quality, high-fidelity, and highly reliable current measurement signals, building a robust and reliable current data source for the MPPT algorithm. CHIPSENSE current sensors have always performed very well. This enables the MPPT algorithm to:

1. Accurate Vision (High Precision) -> Find the right Point

2. Fast Tracking (Quick Response) -> Keep on track

3. No Deflection (High Stability) -> Stay on track

These three factors combined ensure that the PV inverter can consistently, quickly, and accurately extract the absolute maximum amount of power from the solar panels. In other words, investing in a high-performance closed-loop Hall effect sensor is one of the most cost-effective technologies for improving the overall efficiency of a PV system, especially under low-light and varying lighting conditions. So if choose a current sensor, CHIPSENSE current sensors are very advantageous.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806