Today (October 20, 2025) marks the first day of the 2025 Beijing International Wind Energy Conference and Exhibition (CWP2025), a major global wind power event. The theme of the conference is "Promoting Global Energy Transformation, Working Together for Sustainable Development." Global attention is focused on renewable energy. Next month also marks the 30th United Nations Climate Change Conference (COP30). The global wind power industry is facing multiple technological and policy opportunities. Under the goal of carbon neutrality, offshore wind power is a major force in the wind power industry. According to the GWEC2025 report, global offshore wind power installed capacity is growing at an average annual rate of 15%. Meanwhile, offshore wind power is moving towards high power, high reliability, and deep-sea operations. However, offshore wind turbines face risks of high temperature and humidity, salt spray corrosion, and lightning strikes. High current monitoring and adaptability to extreme environments in wind power grid-connected systems have become key industry priorities. CHIPSENSE current sensors also plays an important role in this field.

Wind turbine inverter

Wind turbine inverters are key components in wind power generation systems, responsible for converting and processing the electricity generated by wind turbines to meet the needs of the grid or loads. Their operating principle is to use an inverter bridge, control logic, and filtering circuits to convert low-voltage DC (e.g., 12V/24V/32V) or variable-frequency AC (e.g., AC) to standard 220V/380V 50Hz AC, suitable for use in household appliances or grid connection.

Due to their unique application scenarios, offshore wind inverters differ significantly from onshore inverters in terms of technology, materials, and reliability. Current monitoring requirements are also much higher than those of onshore systems. This is due to the high operational and maintenance costs, harsh operating environment, and higher demands on grid support capabilities of offshore wind power. CHIPSENSE current sensor has also put a lot of effort into product research and development.

Given the unique characteristics of the offshore environment, even more stringent requirements are placed on current sensors themselves:

1. Extremely high reliability and long life: Strives to last as long as the inverter, reducing replacement times.

2. Strong environmental adaptability: Resists corrosion from high salt spray and high humidity environments in the ocean, typically requiring a higher level of protection.

3. Excellent electrical performance:

High Precision: Maintains high measurement accuracy over a wide temperature range, ensuring control accuracy.

Wide Bandwidth: Enables rapid response to current changes to accommodate the high switching frequency control of modern inverters.

Excellent Anti-Interference Capability: The inverter's internal environment is highly susceptible to electromagnetic interference, requiring sensors to exhibit excellent electromagnetic compatibility.

4.Technology selection trends: Traditional current transformers (CT) are gradually being replaced by Hall effect current sensors and more advanced fluxgate sensors, which offer advantages in accuracy, linearity, size, and bandwidth. Core-less rogowski coils are also used to measure high-frequency transient currents.

Wind Frequency Converter

The inverter for an offshore wind turbine is the core control unit of a wind power generation system. Its primary function is to convert the mechanical energy captured by the turbine blades, which fluctuates in speed, into stable electrical energy that meets grid requirements.

The basic operating principle is:

1. Conversion: The alternating current (AC) with varying frequency and voltage generated by the generator is first rectified into DC.

2. Inversion: This DC power is then converted by the inverter unit into AC with stable frequency and voltage, which is then fed into the grid.

During this process, the inverter needs to implement complex functions such as maximum power point tracking (MPPT), active and reactive power control, and grid-connected harmonic control to ensure power generation efficiency and grid security.

Special Challenges of the Offshore Environment

Compared to onshore wind turbines, offshore wind turbine inverters face a more demanding operating environment:

High salt spray and high humidity: These conditions are highly corrosive, placing extremely high demands on the equipment's insulation performance and protection level.

Poor maintainability: Affected by weather and sea conditions, maintenance windows are short and costly, placing extreme demands on equipment reliability and longevity.

Vibration and shock: Continuous vibrations from waves and wind turbine operation require the equipment to possess excellent mechanical stability.

Core Challenges of Offshore Wind Turbine Grid-Connected Systems

Offshore wind turbine inverters and frequency converters are core components of the grid-connected system, fulfilling the critical task of converting wind energy into electrical energy and integrating it into the grid. Among these components, current monitoring is a key requirement for ensuring system stability and efficiency:

Inverter: Converts DC power to AC power for grid connection. Key requirements include DC bus current monitoring, ensuring inverter input stability and preventing overcurrent damage to the IGBTs.

Frequency Converter: Regulates wind turbine speed and grid voltage. Key requirements include AC output current monitoring, ensuring grid current quality and protecting grid security.

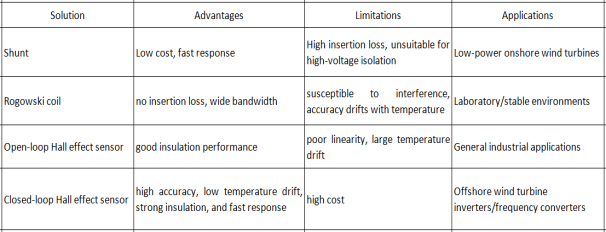

Comparison of Current Monitoring Solutions

Comparing the above table: Closed-loop Hall effect sensors offer significant advantages in accuracy, insulation performance, and environmental adaptability, making them a preferred solution for offshore wind power. Traditional current transformers (CTs) are gradually being replaced by Hall effect current sensors and more advanced fluxgate sensors, which offer advantages in accuracy, linearity, size, and bandwidth. Coreless Rogowski coils are also used for high-frequency transient current measurement. For closed-loop Hall effect current sensors, CHIPSENSE CM9A series current sensor, developed independently by CHIPSENSE, is a good choice.

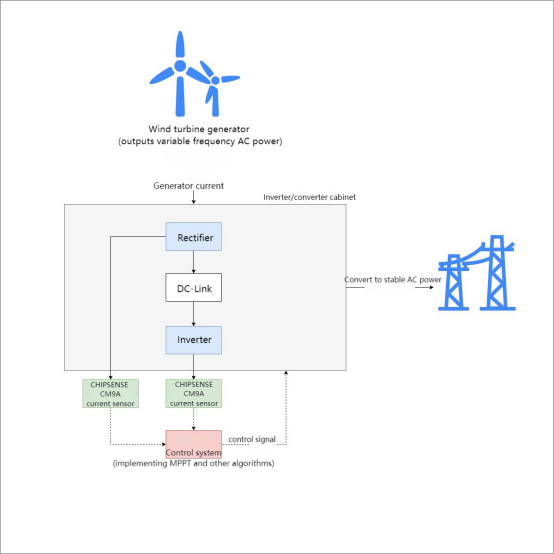

As shown in the figure above, CHIPSENSE CM9A current sensors are mainly deployed at two key points in the converter cabinet.

Generator side (rectifier side): Monitors the variable-frequency AC power output by the generator. Current measurement here is crucial for maximum power point tracking (MPPT). The control system adjusts the generator torque based on this signal to maximize wind energy capture efficiency.

Grid side (inverter side): Monitors the stable AC power input to the grid. Measurements here are directly related to grid power quality (such as harmonic content), active and reactive power control, and device protection (such as overcurrent and short-circuit protection).

Technical advantages

Closed-loop design: Real-time compensation, accuracy up to ±0.3%, linearity error ≤0.1%.

Adaptability to extreme environments:

Operating temperature range -40°C to 85°C, UL 94-V0 flame-retardant housing, CTI Class III A corrosion resistance.

62.68mm clearance and 65.55mm creepage distance, CHIPSENSE CM9A current sensor meeting IEC 61800-5-1 reinforced insulation requirements.

23kV transient withstand voltage and 6kV AC withstand voltage, resistant to lightning strikes and surges.

No insertion loss: Hall effect principle, no impact on system efficiency, response time ≤1μs.

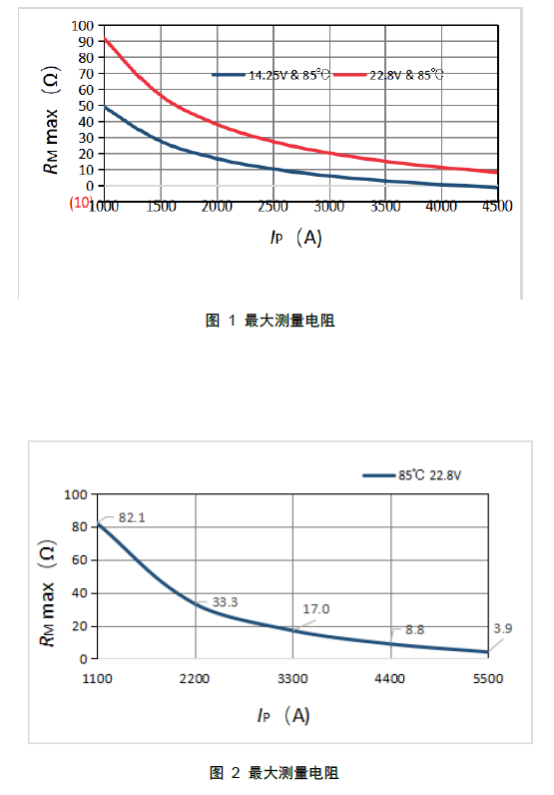

To ensure stable sensor operation within a system, note the following:

Proper configuration: CHIPSENSE current sensor's output signal is directly related to the value of the measuring resistor (RM). This must be accurately calculated based on the input voltage range of CHIPSENSE CM9A H00 current sensor the backend control system to achieve optimal signal sensitivity.

Conclusion:

As the global scale of offshore wind power installations expands, excellent domestic closed-loop Hall current sensors like CHIPSENSE CM9A current sensor will continue to contribute to the carbon neutrality goal and provide "Made in China's intelligence" solutions for clean energy under extreme working conditions.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806