The recent implementation of GB44240-2024, "Safety Requirements for Lithium-ion Batteries and Battery Packs for Electric Energy Storage Systems," marks a historic turning point for my country's energy storage industry. This is my country's first mandatory national safety standard for lithium-ion batteries for energy storage. The standard sets specific technical requirements for insulation monitoring, leakage current detection, fault alarms, and protection mechanisms for energy storage systems. Insulation fault monitoring must simultaneously meet the three key requirements of real-time performance, high precision, and low-temperature drift. This article explores solutions for energy storage insulation monitoring using different monitoring methods. CHIPSENSE current sensors will also demonstrate its advantages within its own product range.

As a vital component of modern energy systems, the safe operation of energy storage power plants is crucial. Insulation failures are a common safety hazard in energy storage power plants, potentially leading to serious accidents and equipment damage. The following provides a comprehensive analysis of the causes, risks, and preventative measures.

1. Main Causes of Insulation Failure

Insulation failure is a common safety hazard in energy storage power plants. Its causes are complex and generally fall into the following categories:

1.1 Environmental Factors

Humidity and pollution: High humidity or suspended conductive particles (dust, salt spray, etc.) in the air can degrade the insulation performance of insulation materials, leading to leakage or short circuits.

Temperature fluctuations: Extremely high or low temperatures can accelerate the aging of insulation materials, resulting in a decrease in insulation strength.

1.2 Material Aging

Insulation Material Aging: Over long-term operation, insulation materials (such as cable insulation and busbar insulation) will gradually age due to heat, mechanical stress, or chemical corrosion, losing their insulating properties.

Manufacturing Defects: Air bubbles, impurities, or uneven thickness during the production process can lead to localized insulation weakness, creating failure points.

1.3 Mechanical Damage

Improper Installation or Maintenance: During cable laying and equipment installation, the insulation layer may be scratched or damaged, posing a potential safety hazard.

Vibration and Stress: Vibration or thermal expansion and contraction during energy storage system operation can cause the insulation layer to crack or peel.

1.4 Electrical Stress

Overvoltage: Transient overvoltages caused by lightning strikes, operational overvoltage, or system failures can break down insulation.

Partial Discharge: Long-term partial discharge can corrode insulation materials, gradually forming a penetrating path.

2. Insulation Failure Risk Analysis

If insulation failures are not discovered promptly, they can lead to the following serious consequences:

2.1 Equipment Damage

Short Circuit: Insulation failure can cause a short circuit, potentially burning out battery packs, inverters, or other critical equipment.

Arc Fault: In high-voltage systems, insulation breakdown can generate arcs, causing fires or explosions.

2.2 Safety Hazards

Electric shock risk: Insulation failures can cause the equipment casing to become electrically charged, threatening the safety of operators and maintenance personnel.

Secondary accidents: Fires or explosions caused by failures can affect surrounding facilities and increase losses.

2.3 Economic Losses

Downtime losses: Failures can cause the energy storage system to shut down, impacting grid peak and frequency regulation or ensuring power availability to users, resulting in economic losses.

Repair costs: Serious failures may require the replacement of a large amount of equipment, resulting in high repair costs.

3. Monitoring and Preventive Measures

To address the aforementioned causes and risks, the following technical measures can be employed for monitoring and prevention:

3.1 Insulation Monitoring Technologies

Online Insulation Resistance Monitoring: Real-time monitoring of system insulation resistance allows for prompt detection of insulation degradation trends.

Partial Discharge Detection: Ultrasonic or high-frequency current sensors are used to detect partial discharge signals and provide early warning of insulation degradation.

Infrared Thermal Imaging: Regularly monitor equipment hotspots to identify abnormal heating caused by insulation defects.

3.2 Environmental Control

Moisture and Dust Prevention: Utilize sealing, dehumidification, and filtration systems in the energy storage power station design to reduce the impact of environmental factors.

Temperature Management: Utilize heat dissipation systems or environmental control to prevent damage to insulation materials from extreme temperatures.

3.3 Material and Design Optimization

High-Performance Insulation Materials: Select aging-resistant and high-voltage-resistant insulation materials (such as cross-linked polyethylene and epoxy resin).

Redundant Design: Utilize double-layer insulation or insulation protective sleeves in key areas to enhance reliability.

3.4 Regular Maintenance

Insulation Performance Testing: Regularly perform insulation resistance and withstand voltage tests to ensure the equipment's insulation is in good condition.

Fault Simulation and Emergency Response Plan: Develop an emergency response process for insulation faults through simulation analysis.

4. Comparison of Insulation/Leakage Current Monitoring Solutions for Energy Storage Systems

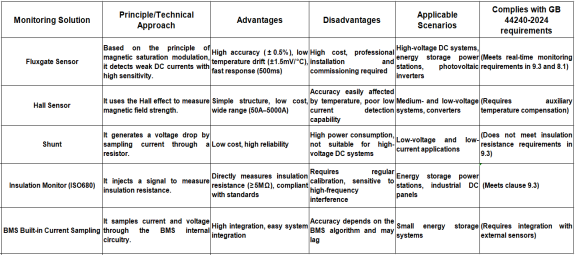

Insulation fault and leakage current monitoring are core components of ensuring safety. The following is a technical comparison of several mainstream monitoring solutions, based on standard requirements and actual application scenarios, for reference only:

As can be seen from the table, shunts no longer meet the requirements. Insulation testers are standard equipment for energy storage power plants, but they are sensitive to high-frequency interference and require integration with fluxgate sensors to enhance interference immunity. Therefore, a single solution cannot meet the needs of a complete energy storage system. The recommended combination is a fluxgate sensor + insulation monitor + BMS. The fluxgate sensor provides high-precision leakage current monitoring, the insulation monitor measures insulation resistance, and the BMS provides coordinated protection, creating a multi-layered safety and security system. Fluxgate sensors can be high-performance and stable domestic components, such as the FR2V H00 series from CHIPSENSE. The performance of CHIPSENSE current sensor rivals that of international brands, and their cost-effectiveness makes them a viable alternative to imported brands. They offer high accuracy (±0.5%) and low temperature drift (±1.5mV/°C), making them suitable for monitoring weak leakage currents (10mA–300mA). With a response time of 500ms, they fully meet the real-time monitoring requirements of GB 44240-2024.

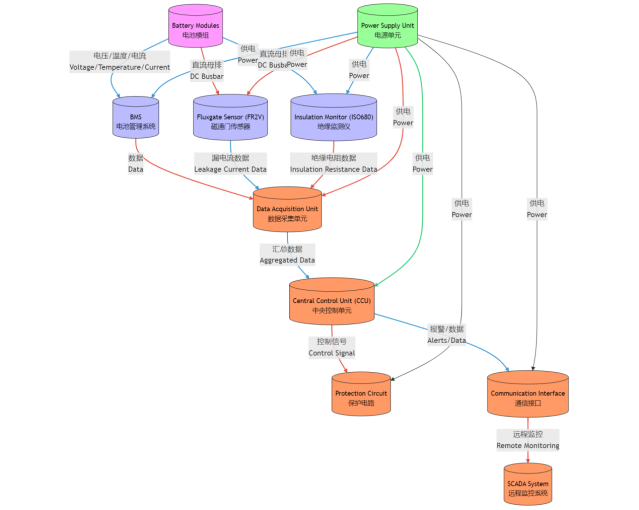

Energy storage system insulation fault and leakage current monitoring combined solution framework diagram

The FR2V H00 series is a current sensor based on fluxgate technology, independently developed by CHIPSENSE. The series current sensor of CHIPSENSE includes FR2V 0.01 H00, FR2V 0.02 H00, FR2V 0.05 H00, FR2V 0.10 H00, FR2V 0.20 H00, and FR2V 0.30 H00 models. Custom specifications are also available. These CHIPSENSE current sensors feature insulated primary and secondary terminals, measure DC leakage current, and output a voltage signal. Made of UL 94-V0 (black), CHIPSENSE offer high accuracy of 0.5% and very low zero-point temperature drift. They comply with IEC 60664-1:2020, IEC 61800-5-1:2022, and IEC 62109-1:2010.

CHIPSENSE FR2V fluxgate current sensors can be used in the following industrial applications:

Residual current measurement

Leakage current measurement in PV inverters (transformerless)

Leakage protection for PV arrays

Leakage detection in stacked DC power supplies

Wide-range single-phase or three-phase current detection (DC or AC, up to ±100A)

Failure mode detection of current sources

Symmetrical fault detection (e.g., at the output of an inverter)

The features of CHIPSENSE FR2V fluxgate current sensors:

Voltage output

Power supply: +12~±15V

Rated residual current RMS: ±10~300mA

Residual current measurement range: ±15~360mA

Operating range: -40~70°C

Accuracy: ±0.5%

Response time: 500ms

Insulation withstand voltage: 3kV

Linearity: 0.5%

The Installation and Deployment Note of CHIPSENSE FR2V fluxgate current sensors:

Although the sensor's secondary output is insulated from the primary, ensure that conductive parts are inaccessible during installation (by installing a protective cover).

Strictly adhere to the IEC 61800-5-1 standard and perform regular calibration. CHIPSENSE current sensor has always been like this requirement.

This sensor is suitable for DC system leakage current monitoring and is not suitable for high-frequency AC or transient current surges.

Conclusion:

Fluxgate sensors offer comprehensive advantages over Hall sensors and shunts in terms of accuracy, response speed, and insulation performance. They are the preferred technical solution for insulation fault monitoring in energy storage power plants and fully comply with the stringent requirements of GB 44240-2024. CHIPSENSE current sensor can be the customer's first choice. However, safety is not absolute; scientific monitoring and standardized operation provide the dual guarantee for risk prevention and control. In the future, as energy storage systems continue to become more intelligent, AI technologies and algorithms will be employed to predict leakage current trends, further enhancing energy storage safety. CHIPSENSE will also develop current sensors that meet customer needs as the times change.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806