A DC panel, also known as a DC power supply system, provides DC power to control, signaling, protection, and automation devices in locations such as substations, power plants, and communications rooms. Industrial DC panels are widely used in power systems, data centers, and communication base stations, providing stable DC power to critical equipment. Their efficient management is crucial for ensuring system reliability and reducing energy consumption. In particular, they can significantly save energy in high-voltage DC power supply solutions for data centers, contributing to the transition to green energy.

With the advancement of smart manufacturing in Industry 4.0, traditional DC panels suffer from monitoring lag, high operation and maintenance costs (difficult fault location due to manual inspections), and significant safety hazards. Intelligent upgrades can achieve millisecond-level fault warnings, improve energy efficiency, and reduce operation and maintenance costs. Through AI-powered diagnostics and remote monitoring, they significantly enhance system safety and management efficiency. They are an essential choice for the digital transformation of power systems. Accurate and secure current monitoring is the cornerstone of intelligent energy efficiency management. CHIPSENSE current sensors are also providing a more solid foundation for the market.

Core Requirements for Industrial DC Panel Energy Efficiency Management

Based on the latest industry technological developments, the core requirements for industrial DC panel energy efficiency management have evolved from simple energy conservation to system-level intelligent and refined management:

High-efficiency energy conversion: Achieve high conversion efficiency (e.g., over 98%), minimizing energy loss and ensuring every kilowatt-hour of electricity is used effectively.

Intelligent charging management: Automatically adjusts charging parameters based on battery status and power demand, preventing overcharging and undercharging and extending battery life.

Load balancing optimization: Ensures balanced current distribution when multiple modules are operated in parallel, extending equipment life and improving system stability.

Comprehensive energy efficiency monitoring: Real-time monitoring of system energy consumption provides energy efficiency analysis data, providing a basis for refined management.

Low-power design: Reduces system energy consumption and improves overall energy efficiency.

Adaptability and scalability: Meets the energy efficiency management needs of diverse industrial scenarios, supporting multiple communication protocols for easy system expansion.

Remote intelligent management: Enables remote monitoring and energy efficiency optimization, reducing operation and maintenance costs and improving work efficiency.

Current monitoring is a fundamental component of energy efficiency management for industrial DC panels. Its importance is reflected in the following aspects:

1. Ensuring safe and stable system operation

Current detection: Monitoring the charging and discharging currents of the DC panel to ensure normal operation is a key component of DC panel testing.

Real-time monitoring of current changes can promptly detect abnormalities such as overcurrent and short circuits, preventing equipment damage or system failure.

2. Optimizing Energy Efficiency Management

Current is a core parameter in energy efficiency analysis. Real-time monitoring of current and voltage changes in a circuit helps users understand the circuit's operating status.

Current monitoring data can be used to analyze system energy consumption patterns, identify energy efficiency bottlenecks, and provide data support for optimizing energy efficiency management.

3. Intelligent Charging Management

The DC panel system's AC monitoring unit monitors key parameters such as AC input voltage, current, and frequency in real time.

Current monitoring data is the foundation for intelligent charging management, enabling the system to automatically adjust charging parameters based on battery status.

4. Ensure Load Balancing

Current monitoring is key to achieving load balancing, ensuring balanced load when multiple modules are operated in parallel.

By monitoring the current of each module, current distribution can be adjusted promptly to avoid overloading a single module and extend system life.

5. Fault Warning and Prevention

Abnormal current flow is often a precursor to system failure. Continuous current monitoring can detect potential faults in advance, enabling preventive maintenance and reducing unplanned downtime.

6. Improve System Reliability

When the DC panel's AC power supply is interrupted, the battery provides continuous power, ensuring circuit breaker operation, control, protection, and monitoring.

Current monitoring ensures that the battery discharge current remains within a safe range during AC outages, ensuring system reliability.

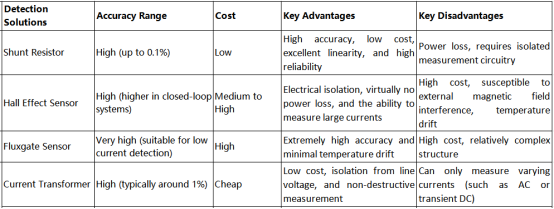

Comparative Analysis of Common Current Detection Solutions for Industrial DC Panels

In the intelligent transformation of industrial DC panels, accurate, safe, and reliable current monitoring is key to achieving energy efficiency management and status warnings. Selecting the right current sensor solution is crucial. The following are common current detection solutions:

Recommendations

For the intelligent upgrade of modern industrial DC panels, the choice of current detection solution directly impacts system safety, energy efficiency, and reliability.

Traditional current transformers have been eliminated from the core circuits of DC panels due to their inability to measure DC current.

Although shunt solutions are relatively low-cost, their inherent insertion loss and electrical isolation safety hazards make them inadequate for modern intelligent DC panels that prioritize energy efficiency and safety.

Fluxgate current sensors offer exceptional precision and are a high-end solution, but they are also relatively expensive and are suitable for detecting minute leakage currents.

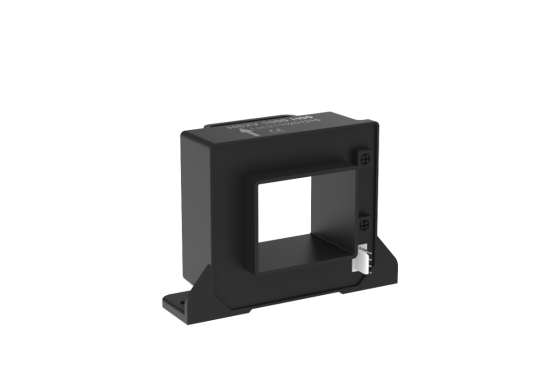

Hall-effect current sensors are currently the preferred solution for current monitoring in DC panels. They are isolated from the circuit being measured, offer excellent safety, and consume virtually no power. In DC panel systems, they are ideal for detecting currents such as busbar discharges, for example, the HS2V series current sensors from CHIPSENSE.

The HS2V series, independently developed by CHIPSENSE, is an open-loop current sensor based on the Hall effect principle. Featuring an insulated primary and secondary sides, it can measure DC, AC, and pulse currents, exhibits zero insertion loss, and is compact. The materials of CHIPSENSE current sensors are comply with UL94-V0 and are compliant with IEC60664-1:2020, IEC61800-5-1:2022, and IEC62109-1:2010 standards. CHIPSENSE this series current sensors includes multiple models with primary current ratings ranging from ±200 to ±1500A RMS and a primary current measurement range of ±600 to ±2500A. These CHIPSENSE current sensors are ideal for intelligent energy efficiency management of industrial DC power panels.

CHIPSENSE HS2V Series Current Sensor Core Features

High-Precision Measurement: Measurement error is only ±1% across a wide temperature range of -40°C to 105°C, meeting industrial-grade accuracy requirements.

Excellent Insulation Performance: Compliant with IEC 61800-5-1 and IEC 62109-1 standards, CHIPSENSE HS2V series current sensor offers an insulation withstand voltage of up to 4.9kV AC/9.9kV impulse, suitable for 550V reinforced insulation and 1100V basic insulation applications.

Fast Response: Response time is less than 5μs, enabling real-time capture of current changes and supporting dynamic load management.

Wide Range Coverage: CHIPSENSE current sensors available ranges from 200A to 1500A meet diverse application needs.

1. Battery Management (Core Application)

The heart of a DC panel is the battery pack (such as lead-acid or lithium-ion batteries). Precise battery management is paramount for energy efficiency and safety. CHIPSENSE HS2V current sensors plays a key role in this area:

Accurate Charge/Discharge Current Monitoring: Real-time monitoring of the battery's charge and discharge current ensures current values are within a safe range, preventing overcharging (which can cause battery damage and swelling) and over-discharging (which can lead to a rapid reduction in battery life or even render the battery useless).

Battery Capacity Calculation (SOC Estimation): By continuously and accurately measuring current and integrating it over time (Ah-hour method), the battery's remaining capacity (State of Charge) can be estimated with relative accuracy, providing critical data for the system to determine how long it can support the load.

Battery State of Health (SOH) Diagnosis: By analyzing current characteristics during the charge and discharge process, combined with voltage and temperature data, it can assist in determining the battery's health status, providing early warning of battery performance degradation and enabling predictive maintenance.

2. Busbar/Branch Current Monitoring

A DC panel consists of a main busbar and various feeder branches. CHIPSENSE HS2V current sensor can be used for:

Total load current monitoring: Installing an CHIPSENSE HS2V current sensors (such as the CHIPSENSE HS2V 1000 H00 or higher range model current sensors) on the main busbar monitors the total system current in real time, assessing the overall load and preventing overload.

Branch current monitoring: Installing an CHIPSENSE HS2V current sensors with an appropriate range on important feeder branches (such as those feeding the main protection device or telecommunication power supply) allows for precise monitoring of power usage in each branch.

Insulation fault monitoring assistance: When used in conjunction with an insulation monitoring device, accurate branch current measurement helps quickly locate ground faults.

3. Charging Module Output Current Monitoring

Monitors the output current of the charging module (rectifier) to ensure it operates within the optimal efficiency range. This also balances the load across multiple charging modules, extending module life and improving overall system energy efficiency.

4. Fault Diagnosis and Safety Warning

Short-circuit and Over-current Protection: CHIPSENSE HS2V current sensor has a fast response speed (5μs) and can quickly detect abnormal inrush current or short-circuit current, providing a signal to the protection circuit for rapid shutdown to prevent further accidents.

Abnormal Power Consumption Analysis: Through continuous monitoring, abnormally high current in certain circuits when unattended may indicate equipment failure or insulation problems, facilitating timely troubleshooting.

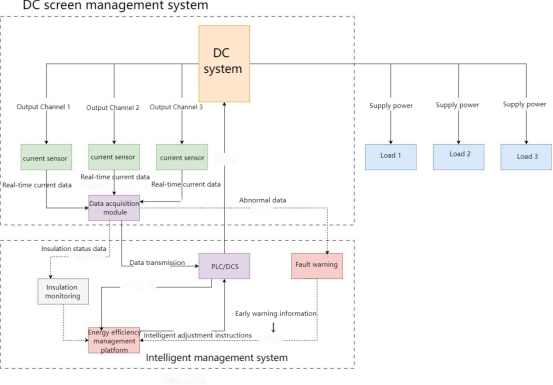

How CHIPSENSE HS2V series current sensor helps DC panels achieve "Intelligent Energy Efficiency Management"

1. Providing a High-Precision "Data Foundation"

Intelligent management relies on accurate, reliable, and real-time data. CHIPSENSE HS2V series current sensors provides precise measurement of DC, AC, and pulse currents, providing the fundamental current data stream for the entire energy efficiency management system. Without accurate data, advanced algorithms and analysis are useless.

2. Achieving "Visualization" and "Quantification"

By uploading CHIPSENSE current sensor HS2V-measured current data to a monitoring unit (such as a PLC or dedicated controller) and further integrating it into host computer software or a cloud platform, the following can be achieved:

Real-time Data Display: Bus voltage, battery current, and branch current are clearly displayed on the monitoring screen.

Historical Data Recording and Analysis: Generates current-time curves to analyze power usage patterns, providing a basis for optimizing operational strategies (such as peak-shifting charging). Energy Efficiency Report: Calculates total power consumption and power consumption by branch, generating energy efficiency reports.

3. Support for "Intelligent" Algorithms and Control

Data-based Optimal Control: For example, based on real-time load current and battery SOC, the charging module's output voltage and current are intelligently adjusted to achieve an optimal charging curve. This ensures fast and safe charging, saves electricity costs, and extends battery life.

Predictive Maintenance: As mentioned above, long-term trend analysis of battery current can predict battery performance degradation and schedule replacements in advance, avoiding system downtime caused by sudden battery failure.

4. Enhanced System Safety and Reliability

Electrical Isolation: CHIPSENSE HS2V current sensor's primary and secondary sides are insulated. This critical feature safely isolates high-voltage/high-current main circuits (such as battery busbars) from low-voltage measurement and control circuits, preventing high voltage from damaging control equipment and ensuring personnel and equipment safety.

No Insertion Loss: CHIPSENSE HS2V current sensor utilizes magnetic induction measurement, consuming no power. Unlike shunt resistors, which generate significant heat and voltage drop when measuring high currents, this improves system efficiency.

Range Selection: Select a model with the appropriate range based on the application described above. For example, a battery main circuit may require an CHIPSENSE current sensor HS2V 500/600 H00, while a branch circuit may only require an HS2V 200 H00. Ensure that the maximum measured current is within the sensor's range, with some margin. This is an key point for CHIPSENSE current sensors.

Installation Notes:

1. Directionality: Always follow the arrow directions indicated in the documentation to ensure that VOUT and Ip are aligned; otherwise, the readings will be reversed.

2. Filling the Vias: For optimal performance, the primary conductor (copper busbar or wire) should fill the HS2V's 40.5mm x 32.5mm vias as closely as possible to achieve the most uniform magnetic field, ensuring measurement accuracy and dynamic characteristics.

3. Safety Protection: As a built-in device, conductive parts (such as the primary busbar) must be inaccessible after installation and must be protected by a protective cover that complies with safety standards (such as IEC 61800-5-1). System integration: Reliably connect the CHIPSENSE current sensor HS2V output signal (usually a voltage signal) to a data acquisition module or monitoring device, and perform anti-interference processing.

Summary

In the practice of intelligent energy efficiency management for DC power panels, the HS2V series current sensors of CHIPSENSE serve as key sentinels in the system's perception layer. By accurately, securely, and in real time capturing the core parameter of current, they convert physical current signals into electrical signals that can be processed by digital systems. CHIPSENSE current sensor provides indispensable data support for real-time monitoring of DC power system status, detailed energy efficiency analysis, early fault warning, and optimized operation and maintenance strategies. They are a solid foundation for building intelligent, efficient, and reliable DC power systems.

CHIPSENSE is a national high-tech enterprise that focuses on the research and development, production, and application of high-end current and voltage sensors, as well as forward research on sensor chips and cutting-edge sensor technologies. CHIPSENSE is committed to providing customers with independently developed sensors, as well as diversified customized products and solutions.

“CHIPSENSE, sensing a better world!

www.chipsense.net

4F, Building C, ZHENGLING.Hi-TECH PARK(Core Space) , No. 2 Cuizhu 2nd Street, Xiangzhou District, Zhuhai, Guangdong Province, China

+86-756-8600806